Video What Makes a Good Reservoir to Inject and Store CO2?

Learn from Science Rob how rock porosity and permeability help us understand and optimize carbon storage.

Delivering reliable, cost-efficient, and long-term CO2 storage

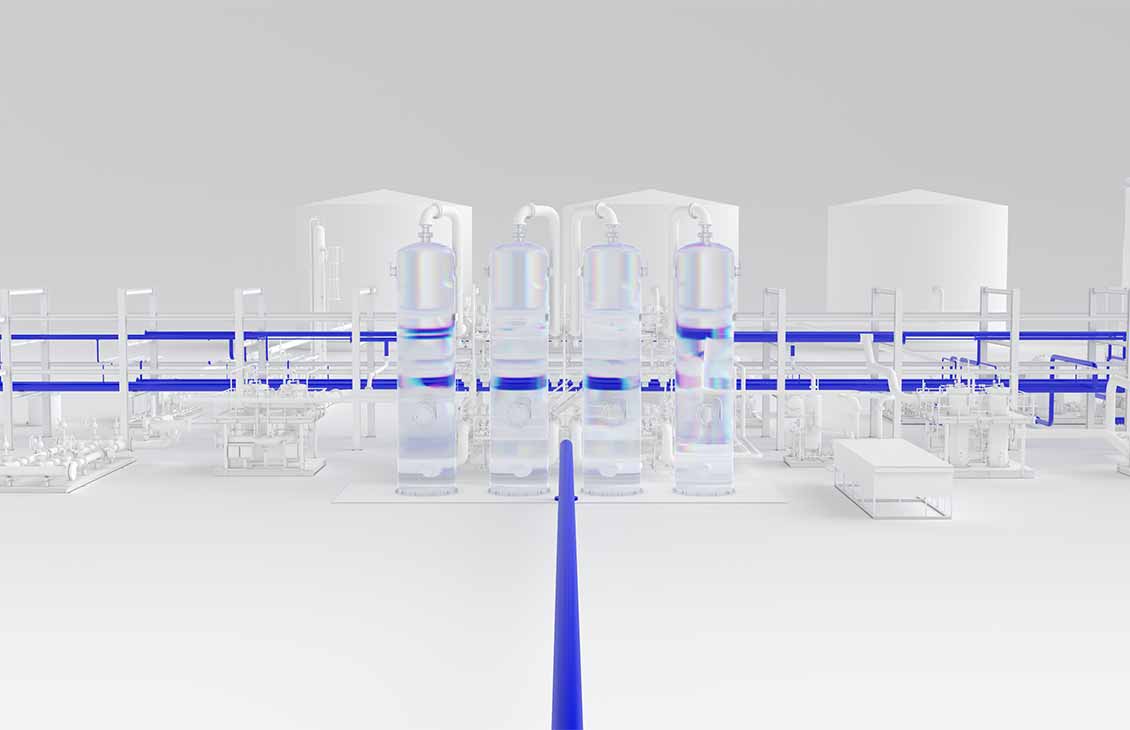

CO2 storage. Effective storage requires precise selection, planning, construction, operation, and monitoring of the sequestration site. Using the right experience, right know-how, and right technologies, SLB optimizes these storage phases to reduce your costs and risks.

SLB has more than 100 years of experience in mapping, measuring, and modeling underground rock formations. And we’ve participated in more than 100 sequestration projects in different geological contexts over the last two decades using innovative solutions. This experience gives us detailed insight into the varied challenges posed by CO2 storage. Integrating geoscience, engineering, and digital capabilities, we’re able to deliver a CO2 storage project anywhere in the world.

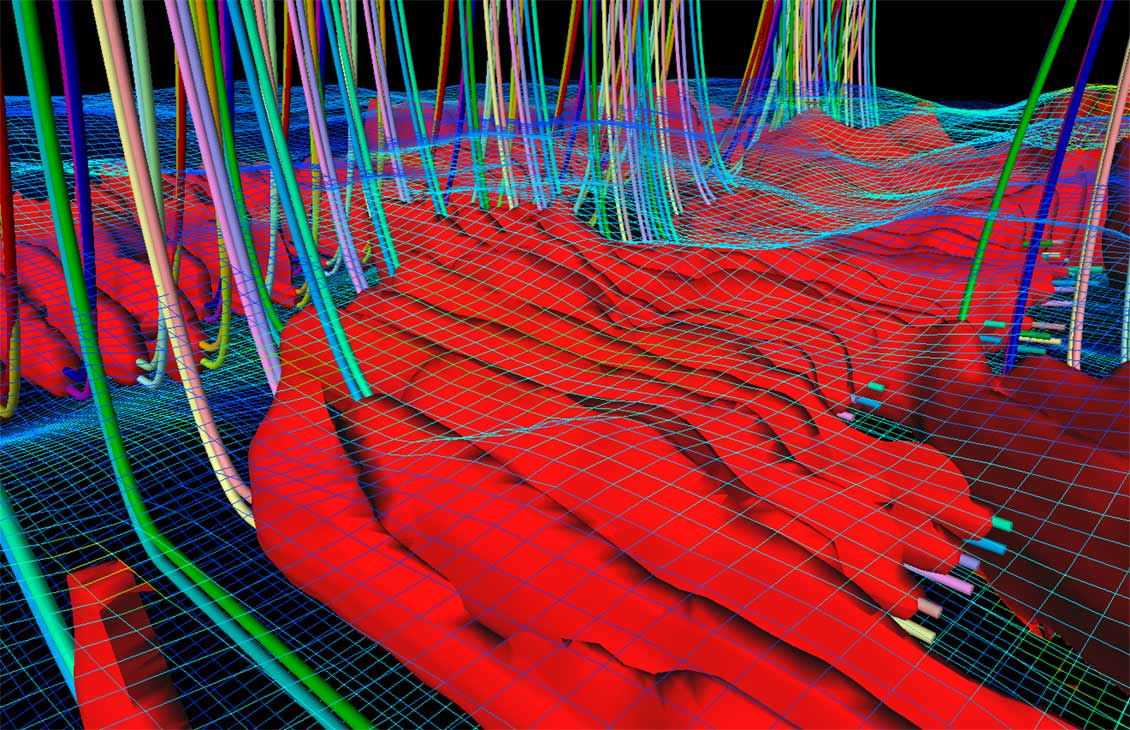

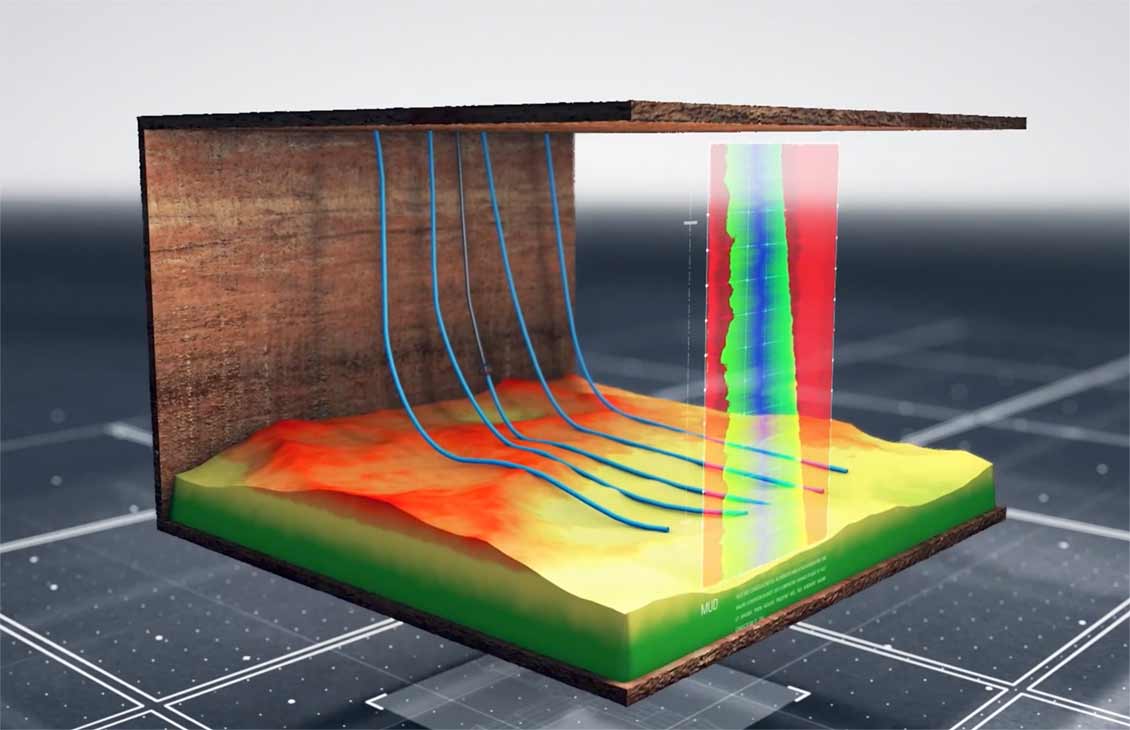

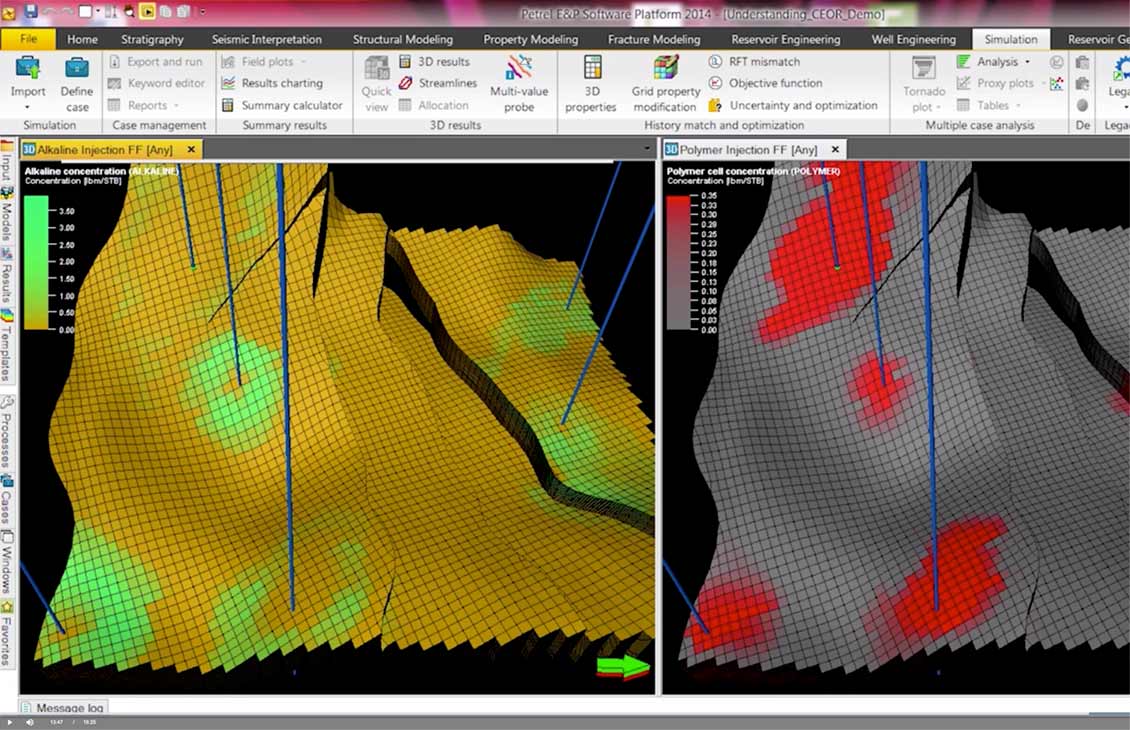

We use our industry-leading suite of modeling tools to progressively model the subsurface during site identification and appraisal. This results in reduced risk, a better understanding of project feasibility, and shorter timeline to final investment decision (FID).

SLB solutions cover the full spectrum, from planning and site development to injection and monitoring. With a tailored suite of CO2 technologies, we help to reduce risk and provide assurance for long-term storage.

We’ve developed modeling tools to predict CO2 plume migration. Combined with our data acquisition technologies during and postinjection, this results in an accurate representation of injected CO2 volumes.

Selecting the right storage site early on is key. This will help avoid unnecessary costs associated with appraising unsuitable sites. We developed a range of methods for screening geological basins and comparing different sites. Within your area of interest, we collect the available data and select candidates for further evaluation.

The key criteria:

Site appraisal describes the many measurements and models needed to confirm the suitability of a site. This phase is essential to understand the geology and behavior in great detail. We

Together, we develop a specific plan for reliable storage. This includes the well location, construction techniques, and monitoring methods.

Injection wells are engineered with the durability to deliver the CO2 to the storage target and isolate and protect the intervening formations. Our well construction services ensure the quality and stability of wells crucial to long-term integrity. And using Optiq fiber-optic solutions, we can evaluate CO2 injection, containment, and well integrity; monitor CO2 behavior; and more.

Before injection starts, we design and develop monitoring wells equipped with sensors. Baseline monitoring readings are then taken from the wells and surface systems. The injection phase typically lasts from 10 to 50 years, and throughout that time, we monitor the storage system to compare actual storage performance against predictions.

Three main types of monitoring are carried out:

CO2 storage is still an emerging technology. Regulation and best practices will evolve in the next decade. Whatever the requirements, at each site, the wells will need to be safely plugged for long-term integrity, the surface equipment removed, and appropriate monitoring continued. High confidence in long-term integrity will only be achieved by having a site that has been well chosen, well designed, well operated, and well monitored.

That’s what we do.

Enabled by our digital capabilities, technologies, and expertise, SLB was selected to use the DELFI cognitive E&P environment on the Norwegian CO2 project by the Northern Lights JV to streamline subsurface workflows and longer-term modeling and surveillance of CO2 storage. The JV was established to develop the world’s first open-source CO2 transport and storage infrastructure—accelerating decarbonization opportunities for European industries to store up to 5 million metric tons of CO2 per year based on market demand.

Nonaqueous solvent technology drives carbon capture cost reductions across hard-to-abate industries

This virtual course will familiarize management personnel across industries about CCUS. Topics include a discussion on the global outlook for CCUS, integrated workflows for projects, key technologies, case studies, and more.

Watch as our SLB experts discuss the challenges facing the CCUS industry and how we’re poised to ensure your project’s success.

Real-time monitoring and control with modular completion equipment and Optiq fiber-optic solution. View

Subsurface data acquisition, analysis, and modeling creates evaluation blueprint and future Class VI injection well permitting. View

Optiq Seismic solution efficiently acquired data across four wells using both multimode and single-mode fiber. View

Differentiated technologies and deep expertise to optimize your carbon capture and lower costs. View

SLB’s bold approach to a practical and viable carbon abatement solution. View

Planning the carbon storage site with capacity, injectivity, and containment in mind. View

Depend on SLB to maintain the integrity of your carbon storage for the future. View

Proactive and integrated monitoring to keep your carbon sequestration operations running smoothly. View

Projects fit to your objectives using consultancy, partnerships, and flexible business models. View

Capture all aspects of your models from reservoir to product distribution. View

Industry-standard simulator for ever faster high-resolution reservoir simulation with unrivaled quality. View

Better understand geomechanical risks and optimize production. View

Harness the power of light for multidomain measurements in a fraction of the time of conventional methods. View

Use the industry-standard tool for dynamic multiphase flow simulation. View

Industry-reference reservoir simulator for black oil, compositional, thermal, and streamline reservoir simulation. View

Enable discipline experts to work together and make the best possible decisions—from exploration to production. View

Unite planning and operations in a multidimensional environment. View

Accelerate your path to net zero with flexible, reliable, collaborative, and cost-effective solutions across the CCUS value chain.

Explore more