Video Working for Mutual Value

Sarah Gay of bp joins Donnie Ross of SLB to explain how collaboration helps manage change and risk.

Integrating project preparation, prospect definition, drilling performance, and informed completions and production

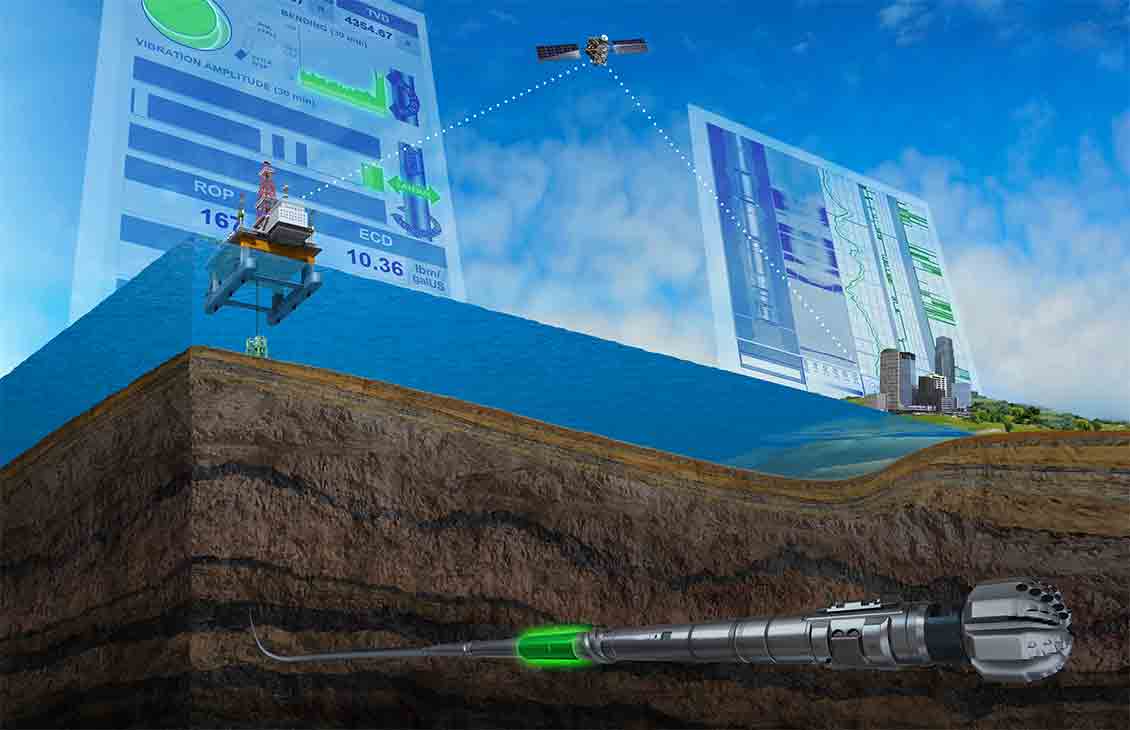

Deepwater project managers are required to juggle time, cost, and quality commitments. To combat expensive spread rates, you need to employ advanced drilling and evaluation technologies to most efficiently reach the well’s target depth and meet the project objectives. Deepwater programs are challenged to drill fewer wells while maximizing well information extraction. The numerous technical challenges coupled with the economics of deepwater projects make it essential to get things right the first time.

That’s where the people of Schlumberger come in. We have the unique combination of deepwater experience, expertise, personnel development programs, technology, and global presence to help operators deliver successful projects.

Drill, evaluate, and enlarge hole in one run while reducing wellbore stability risk to save considerable time and resources in costly deepwater arenas.

READ TECH PAPER

Competent, multiskilled, certified people are a pillar of deepwater success. Our rigorous deepwater certification process ensures that only specially trained, experienced engineers are assigned to deepwater projects. We use an interactive system that records and tracks Schlumberger deepwater personnel from their first day of employment, mapping expertise and experience by

This unique tool matches the best-qualified personnel to projects based on individual skill sets and experience rather than on personnel location. Familiarity

with rig-specific activities and processes reduces the amount of

learning required in the environment and improves service delivery.

And our deepwater-certified personnel never stop learning. They undergo a continual learning process in workshops and through hands-on experience to learn the latest domain concepts and theories.

We apply our prior experience and local knowledge to your projects to help you navigate local regulatory requirements and take the best logistics decisions for working in remote locations. Breaking down communication silos and interfaces, one integrated service project manager (ISPM) coordinates activities, including with third-party providers.

An integrated services model (ISM) is available when we work together on multiple services and extends to managing third-party services. There are multiple examples and variations of the ISM service and it is dependent on client and project needs and requirements.

We assign people, equipment, and resources according to the needs of each project. In some cases, dedicated personnel and downhole equipment will travel with the rig, and the local Schlumberger bases provide the technical support. This minimizes any equipment availability uncertainty and allows for full accountability.

Proactive preparation reduces the potential for NPT and increases efficiency and safety of operations. Our project-startup guidelines define the steps required for your specific deepwater mobilization and encompass industry standards, regulatory requirements, operator specifications, and HSE operating standards. Operational aspects include

We rank and plot risk exposure, complexity and processes, people and competency, and equipment on a readiness matrix. All parties are made aware of progress, which significantly reduces unplanned events, NPT, and operating costs over the long term.

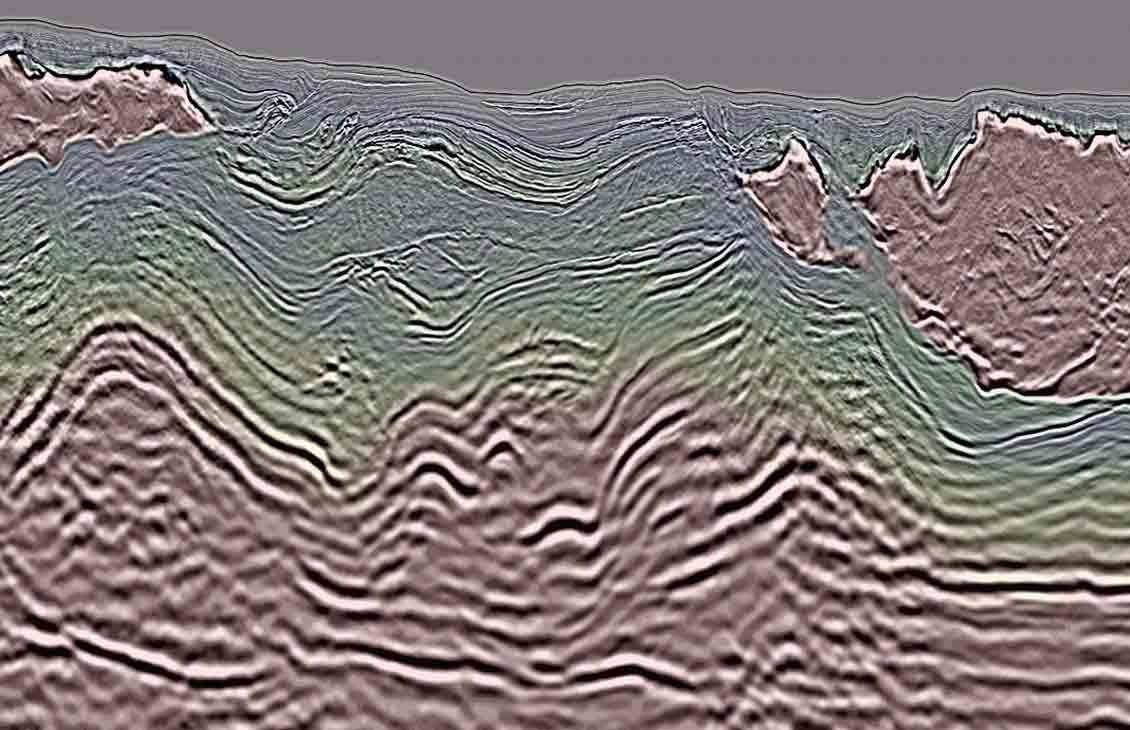

Improving reservoir characterization and knowledge management with 3D modeling of seismic and drilling data, formation evaluation logs, and well test data.

Derive high-resolution velocity and anisotropy models from seismic data using a two-way wave equation. View

Optimize casing design, column height estimation, seal integrity analysis, and overpressure compartmentalization. View

Monitor formation pressure while drilling to calibrate pore pressure models. View

Achieve accurate reservoir properties measurements and a better understanding of fluid and rock interaction. View

Collect virtually contamination-free fluid in a fraction of the time. View

Perform formation testing where previously not possible. View

Improve safety, efficiency, reliability, and sticking avoidance with a conveyance solution for every well environment. View

Enhancing recovery ratios and keeping surprises—and the downtime and costs they bring—to a minimum.

Manage downhole conditions and BHA dynamics while drilling using actionable, integrated data displayed on a rigsite dashboard. View

Expert directional drilling services for high-quality wellbores that stay in the “sweet spot”—your optimal production zone. View

Enhance performance and reliability, simplify operations, and decrease both personnel requirements and equipment footprint. View

Our solids control technologies and services maintain drilling fluid integrity and minimize waste. View

Acquire formation evaluation and drilling optimization data during drilling operations. View

Improve efficiencies, reduce costs, and minimize HSE impact in demanding applications, including HPHT, deepwater, and depleted wells. View

Designing completion configurations for the long term to help ensure efficient recovery of deepwater reserves.

Optimize recovery with digital data and production control that minimize interventions and help you manage water and gas production. View

Extend well production with gravel- and frac-pack services, fluids, screens, ICDs, and tools for openhole and cased hole wells. View

Reduce risks with systems for deep water, high pressures, and extreme temperatures. View

Metris permanent monitoring systems represent a step change in real-time reservoir and production surveillance. View

Monitor with distributed temperature sensing (DTS) and distributed acoustic sensing (DAS) systems. View

Minimize fallout of shaped-charge debris and reduce perforating gun shock. View

Using effective flow assurance and artificial lift strategies, plus real-time and remote monitoring and control technology.

Increase recovery for the life of your field with integrated solutions that have reliability built in. View

Increase recovery for the life of your field with industry-leading, reliable systems. View

Expand the operating limits of conventional systems with a range of products and services for artificially lifted wells. View