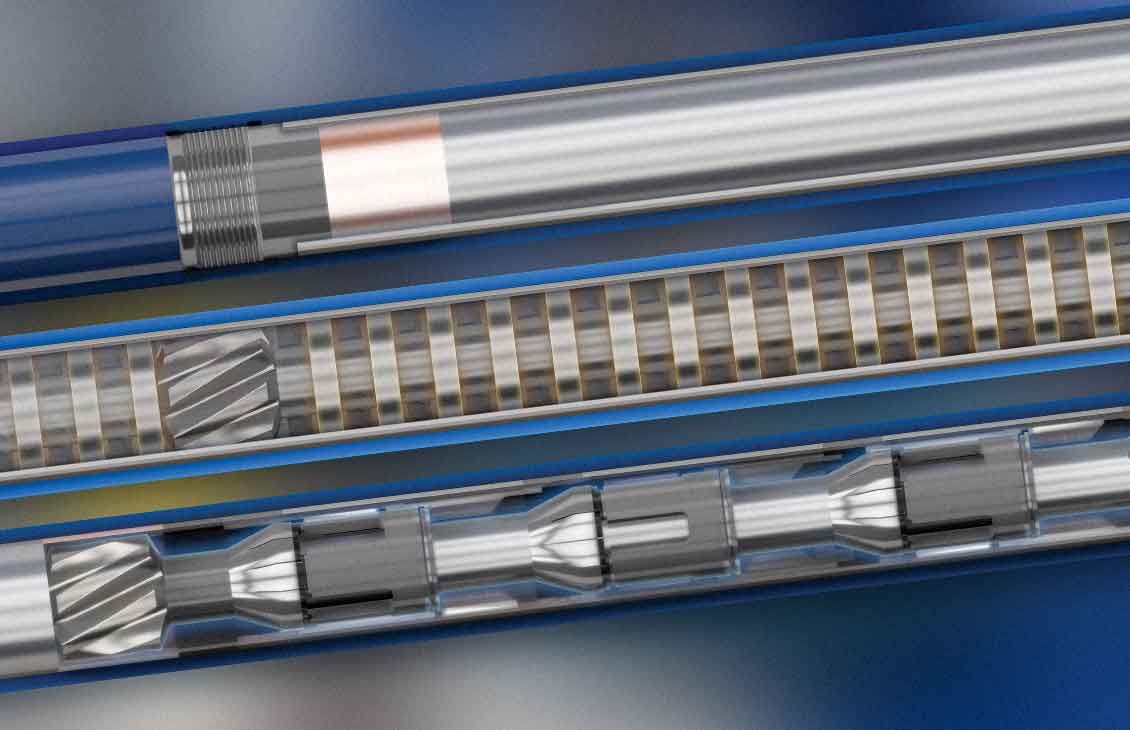

Case Study Dampening tool increases ROP and drills 4,552 in single run

HFTO Suppressor tool enables single 4,552-ft run

Reach and stay in the productive zone faster and more efficiently

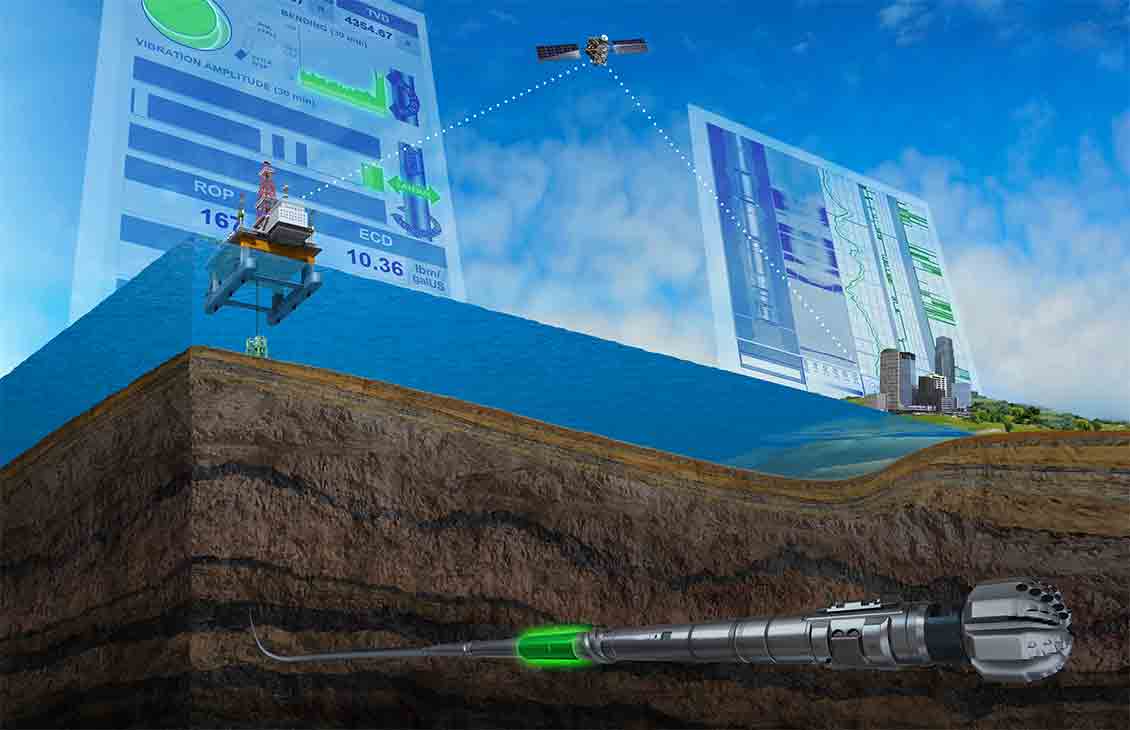

SLB provides the expert directional drilling services needed for high-quality wellbores that stay in the “sweet spot”—your optimal production zone. Our proven trajectory control technologies provide precise directional control using our LWD and MWD services that deliver high-quality data, enabling time-critical decisions for accurate drilling of extended-reach horizontal and complex directional wells.

We have unmatched capabilities that integrate well construction digitization and technologies such as at-bit steerable systems and definitive dynamic surveying. We invented the rotary steerable system, and we now lead the industry with groundbreaking autonomous directional drilling. Additionally, we closely collaborate with directional drillers and directional-drilling contractors using real-time analysis solutions to monitor downhole conditions, manage BHA dynamics, improve casing-point selection, and reduce drilling risks—all enhancing drilling optimization.

Our advanced BHA instruments can measure the path of the wellbore in three-dimensional space and map volumetric data on a reservoir scale; see up to 100 ft ahead of our innovative drill bits; make geosteering adjustments autonomously; and provide data links to communicate these downhole measurements to the surface. And it all enables the directional driller to optimize the wellbore path with pinpoint accuracy no matter the reservoir, no matter how complex the well, no matter how long the lateral. Read this case study demonstrating how SLB’s directional drilling capabilities extend your reach for better well economics.

Raul Suarez is our directional drilling expert. Learn how our capabilities, technologies, and systems can help you drill to TD in less time while staying in your optimal production zone.

Contact RaulEnhanced Technologies for Improved Well Economics with Repeatability, Reliability, and Reduced Carbon.

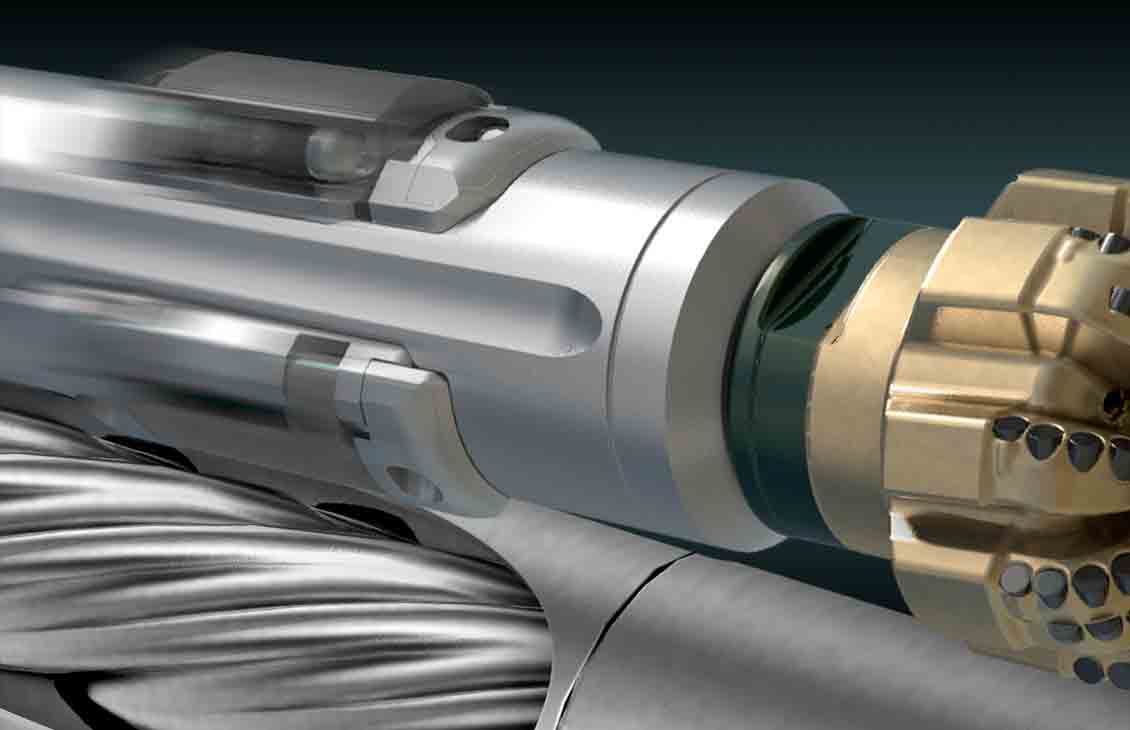

Integrated steering and cutting structure technology for unprecedented DLS capability, durability, and ROP.

RSS offerings for maximum directional control.

Achieve precise wellbore positioning on any rig type worldwide. View

Leverage increased abrasion resistance, higher DLS for tighter curves, and better directional control while lowering emissions. View

Maintain tight directional control through the magnetic zone of exclusion and monitor stick/slip, shock, and vibration. View

This high-powered system is the only fully rotating RSS that delivers higher ROP with more power, improved downhole reaction, and tighter directional control. View

Drill complex curves and trajectories and sidetrack without making an extra trip. View

Improve performance in ultraHT wells with a fully rotating RSS that operates normally at 200 degC [392 degF]. View

Actively and automatically maintain verticality from surface to TD through automatic inclination control. View

Real-time analysis solutions.

Monitor and analyze processes and downhole conditions in real time. View

Manage downhole conditions and BHA dynamics while drilling using actionable, integrated data displayed on a rigsite dashboard. View

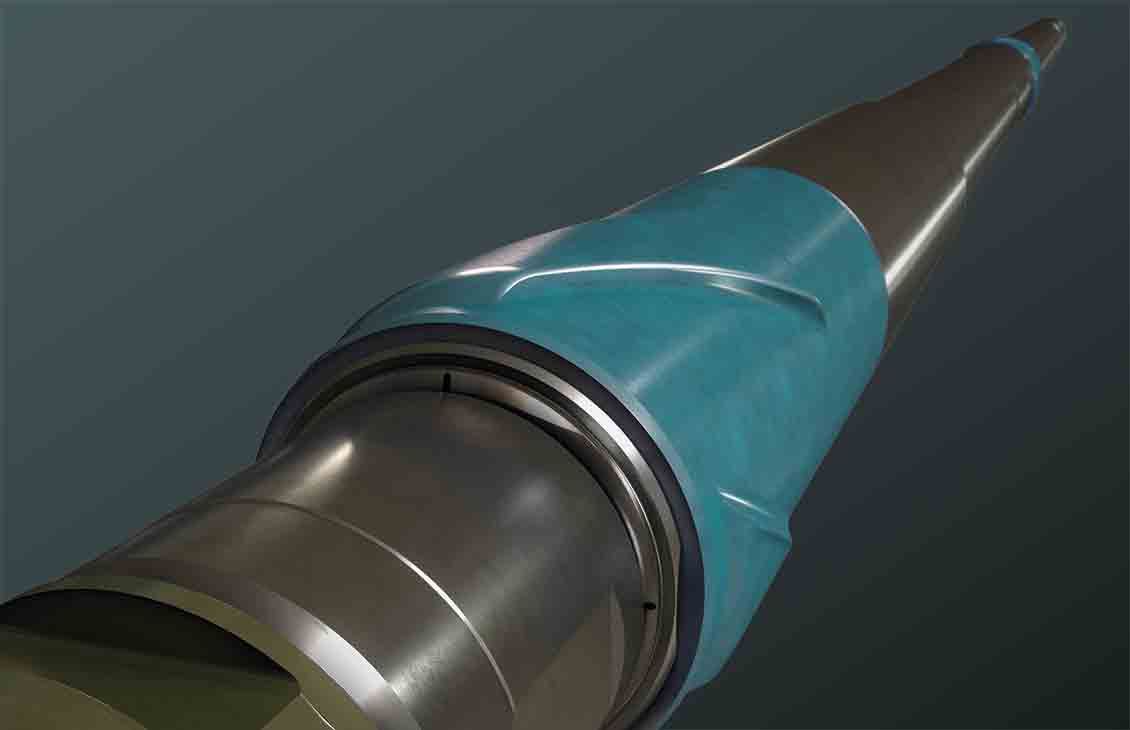

The dampening tool minimizes risk of BHA tool failure and enables PDC cutters to stay sharp for faster drilling. View

Reduce impact loads produced during milling and drilling operations, increase ROP, and extend equipment life. View

Motors that enhance torque output and directional control.

We offer a large variety of fit-for-purpose positive displacement motors for high-volume and high-tier applications. These motors not only provide improved reliability for extended run intervals, they may also be paired with DynaForce DTX thin-wall motor power sections and DynaPower motors elastomers to deliver performance in the harshest drilling environments.

Additionally, combining our high-performance drilling motors with the ability to model application- or basin-specific motors means we can provide unique solutions to satisfy any customer need.

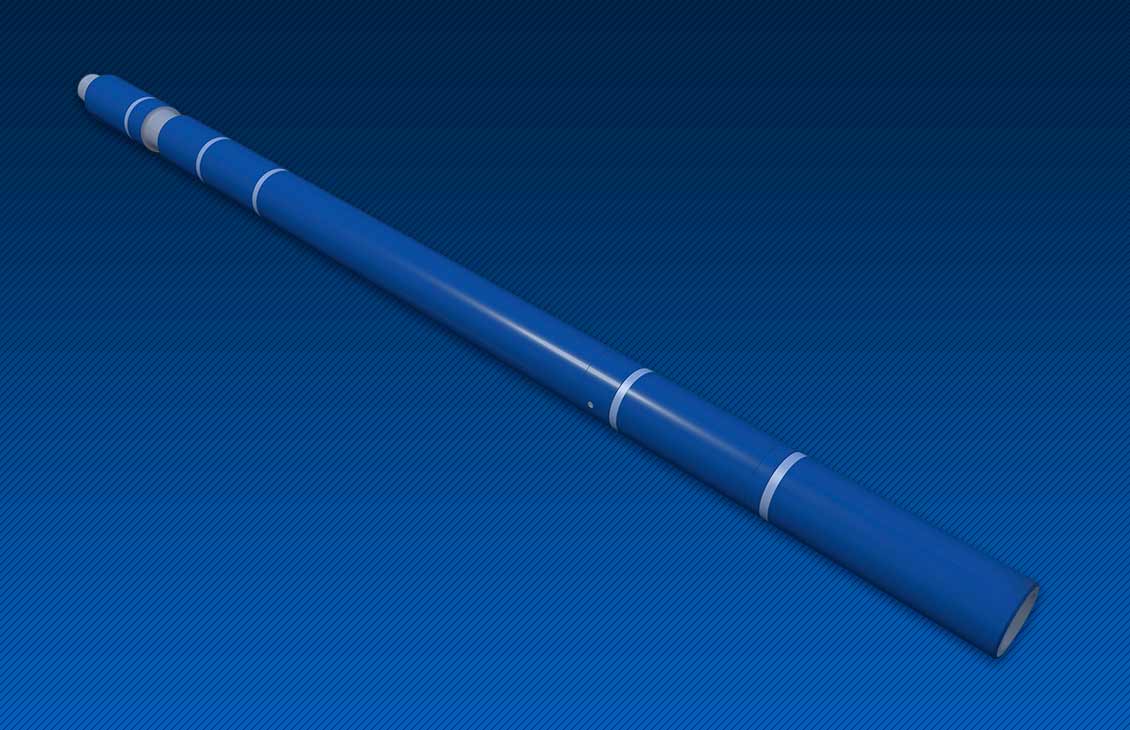

Neyrfor turbodrilling systems that increase rpm.

Maintain optimal power while on bottom and extend run time. View

Efficiently convert hydraulic energy into mechanical energy for improved ROP and efficiency. View