Modeling and simulations to enable realizing the full potential of an electric well completion are easier than ever with the Petrel™ E&P software platform and INTERSECT™ high-resolution reservoir simulator. At the completion concept selection stage, the Petrel Advanced Completion Optimization (ACO) module and rich functionality of the Petrel platform enable identifying the well design—single-bore or multilateral well, number of laterals, conventional, inflow control device (ICD), or intelligent completion—that will maximize recovery at the well or field level.

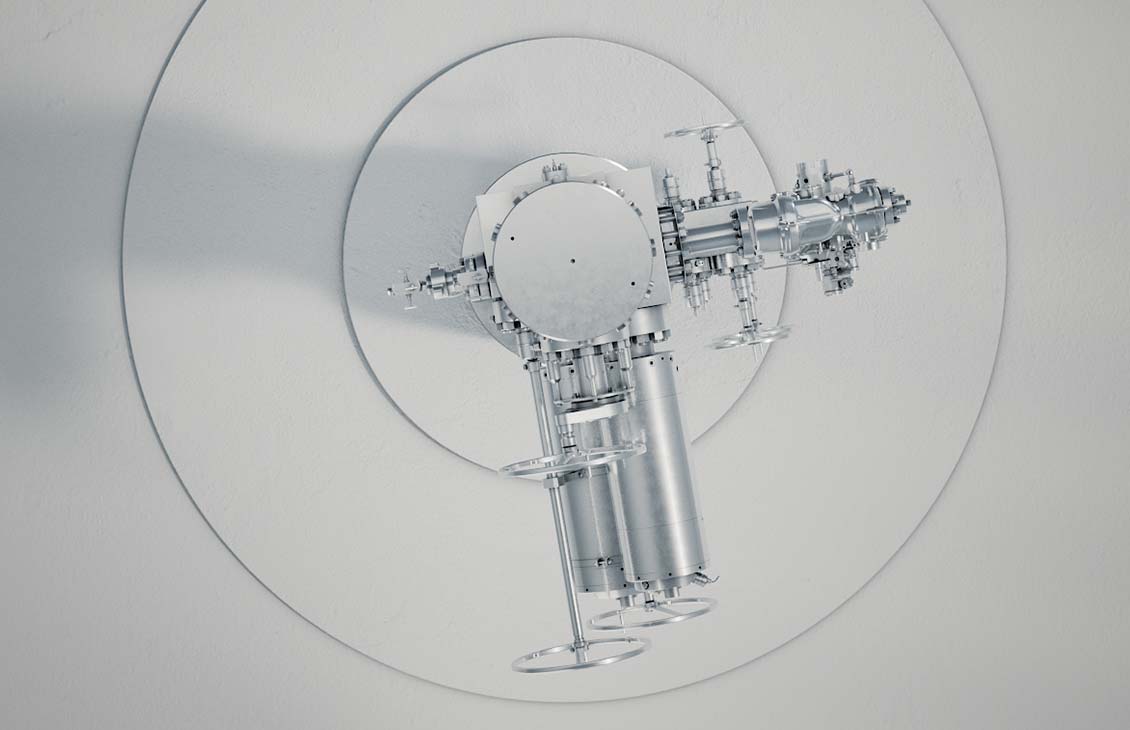

Considering an intelligent completion? Your reservoir and completion engineers can use Petrel ACO to optimize interval control valve (ICV) selection for maximizing hydrocarbon recovery and delaying breakthrough of unwanted fluids, such as water and gas. The workflow can assess use of ICVs with on-off, multiposition, or infinitely variable chokes—unique to SLB. Electric infinitely variable ICVs provide high-precision control of each interval’s production contribution.

An electric intelligent completion can improve recovery, suppress water and unwanted gas production, reduce well count, and enable decreasing or reusing surface and subsea infrastructure—while requiring only the power needed to operate a 100-W light bulb. Electric completions eliminate the constraints imposed by hydraulic and electrohydraulic completions on wellbore length and the number of intervals controlled per well.