Eliminate or reduce flaring

Achieve zero flaring in your operations or minimize its impact

Net zero or otherwise—we'll help you reach your targets

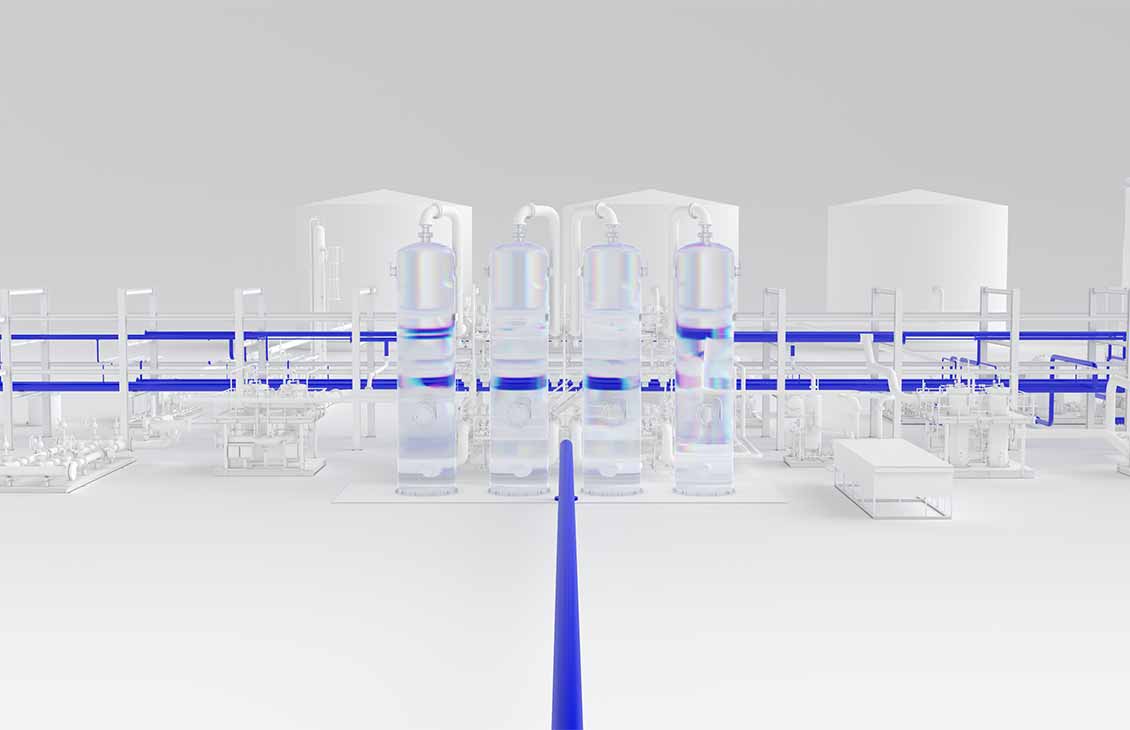

No matter what stage you’re at in decarbonizing your operations, we can help you achieve tangible results by eliminating or reducing the impact of your flaring activities. We have invested in industry expertise, partnerships, and innovative technologies to help you drive business performance while simultaneously reducing your environmental footprint.

Eliminate what you can. Flare efficiently when you must.

The energy industry faces a dual challenge of reducing emissions and meeting global energy demand. Eliminating or reducing flaring achieves both goals by freeing up energy that would otherwise be burned. We offer solutions to help our customers achieve zero flaring or minimize emissions in routine and nonroutine flaring operations. Where flaring is unavoidable, we work to maximize combustion efficiency and minimize CO2e emissions. Our team works to understand your goals and help you meet them with our end-to-end emissions solutions and quantifiably proven footprint-reduction technologies.

Aim for quick wins and long-term strategy

Target routine and nonroutine flaring emissions.

Eliminate where possible

Achieve zero flaring in your operations.

Minimize when necessary

Reduce flare volume and maximize burn efficiency.

Find commercially viable alternatives

Monetize gas that would otherwise be flared.

SLB End-to-End Emissions Solutions

Our experts deliver comprehensive services to help you measure, monitor, report, and ultimately eliminate methane emissions and routine flaring quickly and cost effectively. This includes gas-to-X technologies to help find alternatives for monetizing gas that would otherwise be flared.

BP Oman reduces >80,000 t of CO2 emissions for the Khazzan Project

Working together, BP Oman and SLB implemented a green completions technique that adapted a well cleanup solution from a greenhouse gas-producing activity to one that prevents GHG emissions.

The result was zero-flaring delivery of new wells to a central production facility.

Integrated approach reduces environmental impact from well testing activities and sets benchmark, New Zealand

In a collaborative multiphase effort, a customer and SLB implemented a well testing solution that reduced the environmental impact of these activities offshore New Zealand.

Learn how we helped implement a well testing solution to decrease total gas and condensate volumes flared and ensured no overboarding of treated fluid.

Talk with an expert

Contact usExplore related products and services

-

EverGreen

Minimal environmental impact well effluent burnerAchieve well test and environmental objectives with fallout-free, smokeless combustion of liquid hydrocarbons. View

-

Zero-Flaring Well Test and Cleanup

Lower emissions. Greater returns.Achieve flare-free operations using fit-for-purpose technologies and techniques View

-

Ora

Intelligent wireline formation testing platformExperience your reservoir like never before. View

-

Symmetry

process simulation softwareCapture all aspects of your models from reservoir to product distribution. View

-

Reda Multiphase HPS

Horizontal multistage surface pumpHandles up to 90% gas volume fraction; used for zero-flaring well tests, well cleanup, and production boosting. View