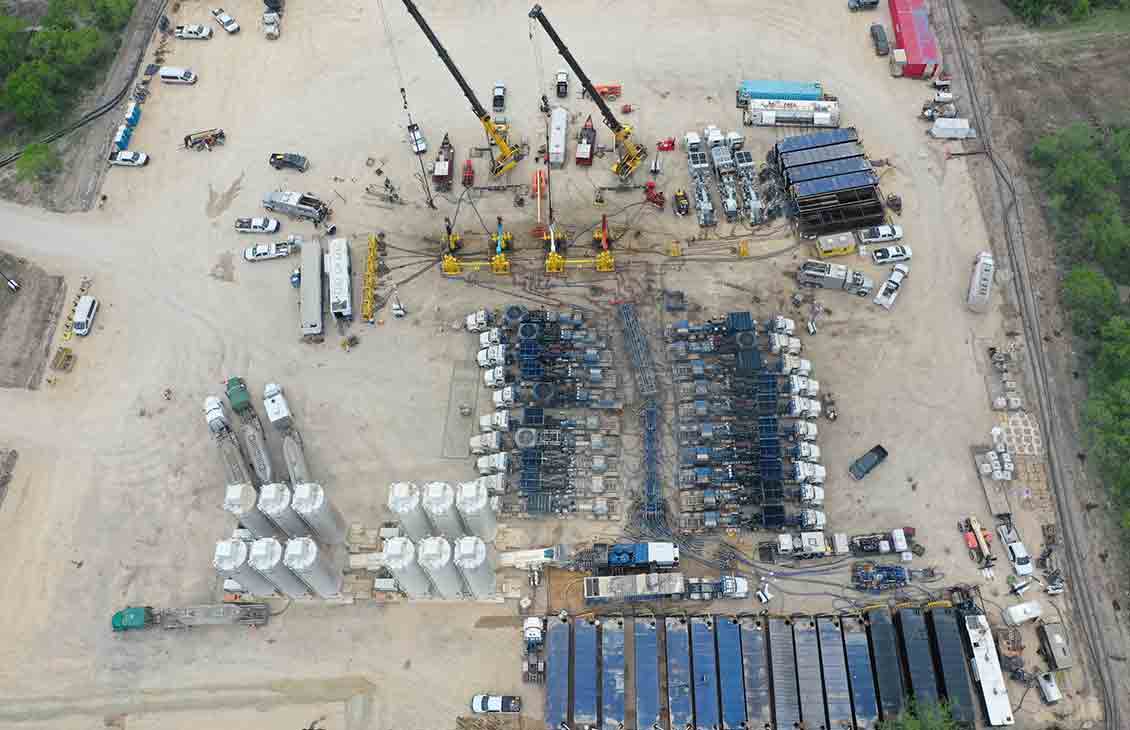

Case Study 20% More Pumping Time per Day During Zipper Fracs, Bakken

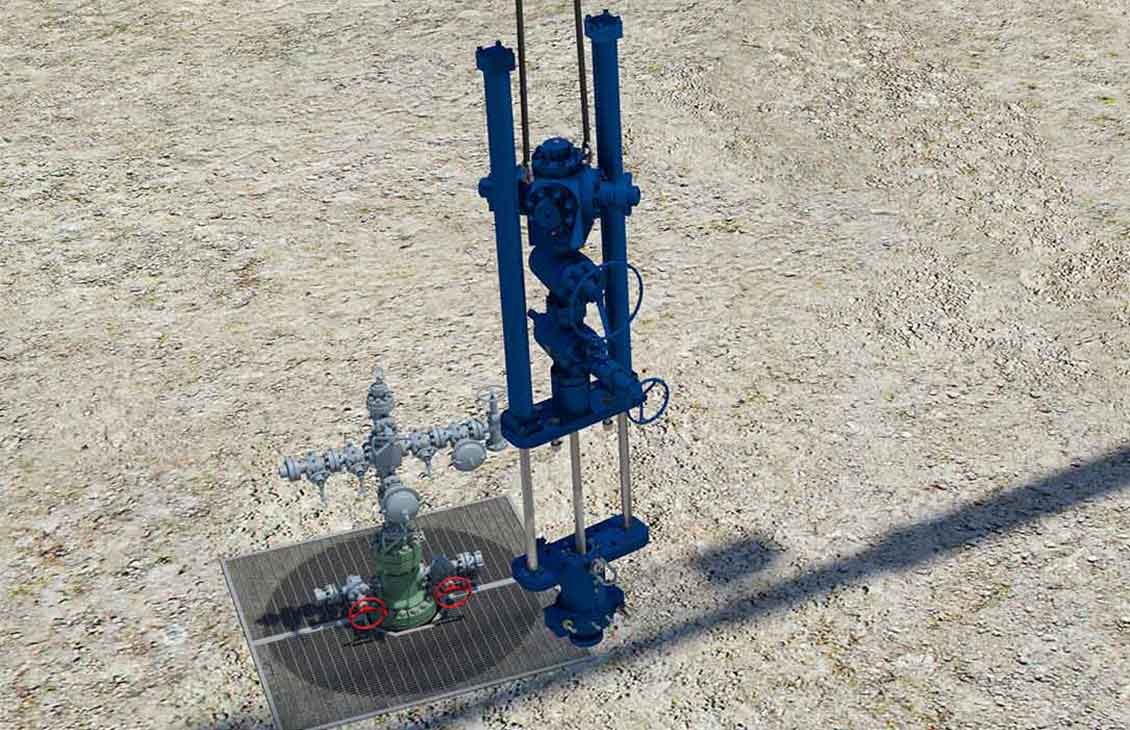

Automated digital control of frac tree and manifold valves reduces downtime, risk, and environmental impact.

Maximize stimulation efficiency with reliable technology

Streamline fracturing operations with reliable and efficient technology used in land and offshore applications.

Choose a more reliable alternative to multiple conventional small inline check valves on frac iron. View

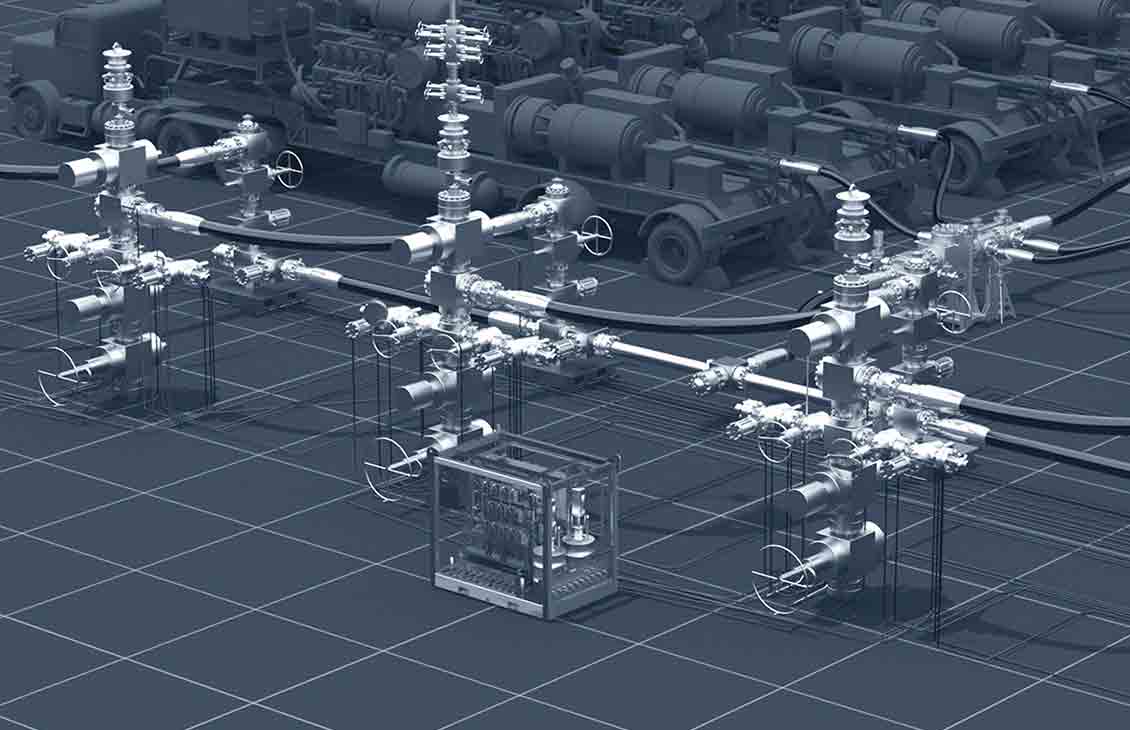

Increase hydraulic fracturing process control, reliability, and efficiency through automation. View

Simultaneously stimulate two wells using a single stimulation fleet to save time and cost without sacrificing well performance. View

Speed up multiwell pad rig-up with a flexible, erosion-resistant conduit that couples the frac manifold to the frac tree. View

Eliminate red zone activities and reduce greasing time with optimized remote valve maintenance. View

Streamline zipper frac operations and eliminate cut wireline by automating frac valves. View

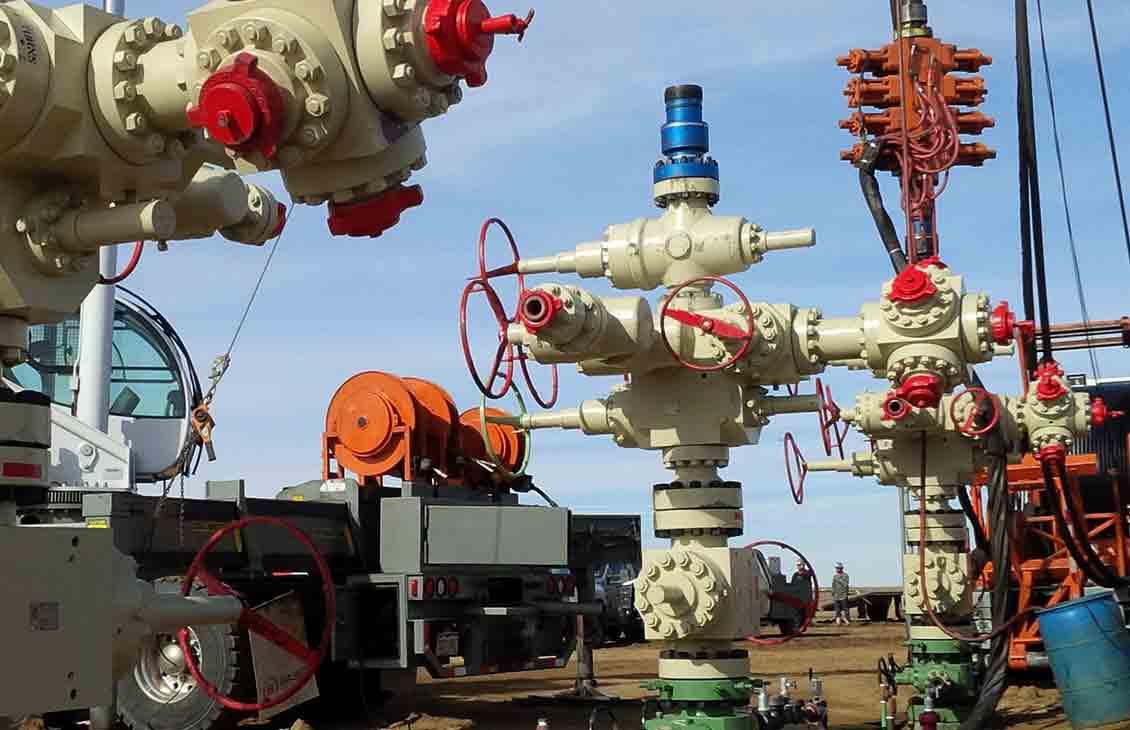

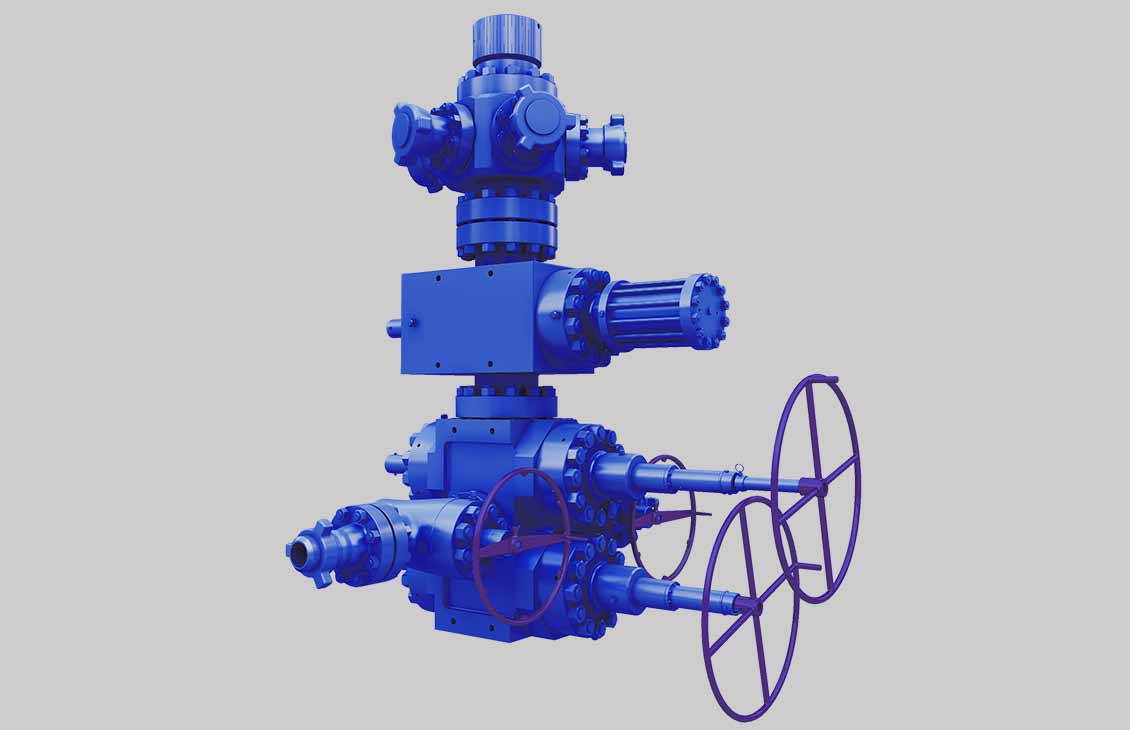

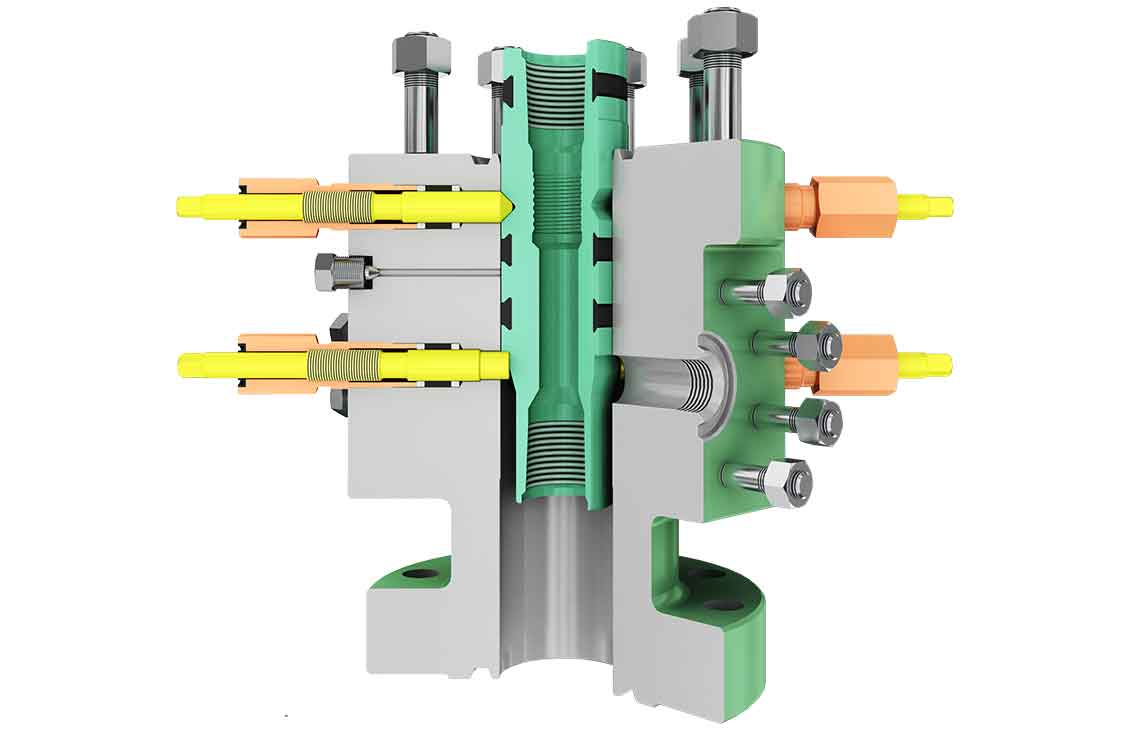

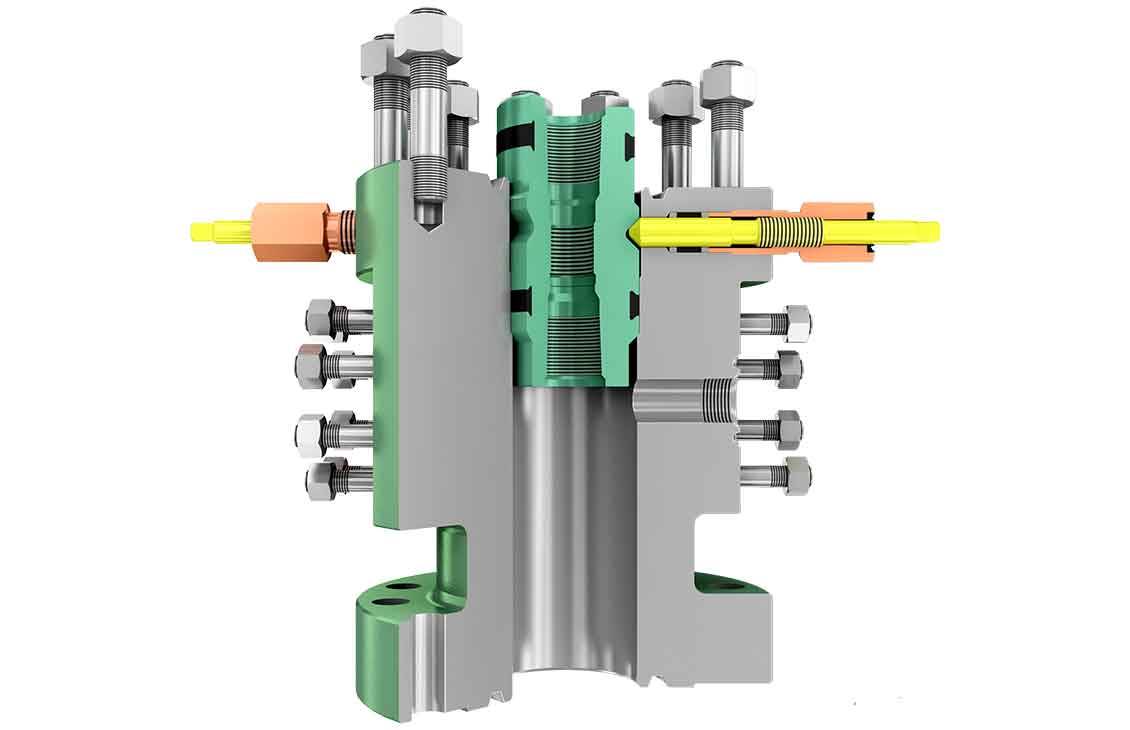

Optimize simultaneous multiwell operations with a shorter, lighter design compared with conventional frac trees. View

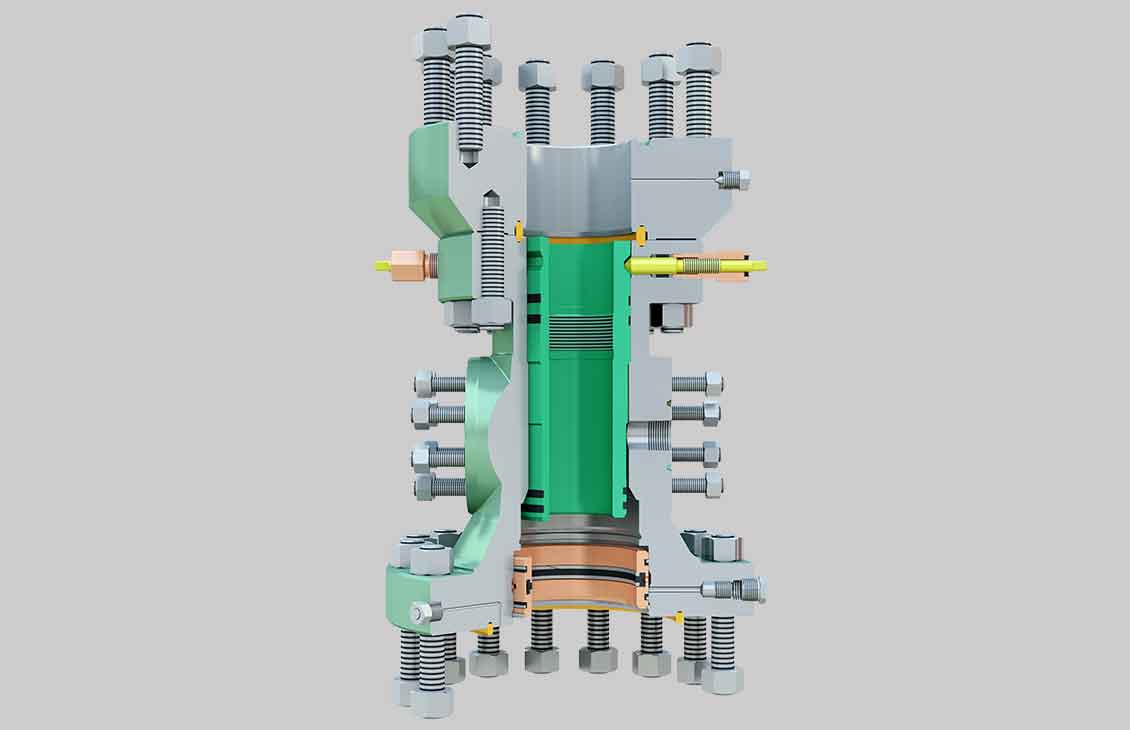

Handle hydraulic fracturing pressures up to 15,000 psi and minimize leak paths with a compact Cameron composite frac tree. View

Maximize corrosion and erosion protection, streamline maintenance, and minimize NPT and related costs. View

Eliminate unnecessary rig-up and rig-down between frac stages with flexible, modular frac manifolds controlling fracturing fluid flow. View

Automate frac valve operation but maintain a contingency to minimize NPT. View

Improve reliability and reduce potential leak paths on multiwell pads with a safer, faster alternative to conventional frac iron. View

Replace risky hammer unions for connecting high-pressure frac hoses with faster setup, safer clamp system. View

Optimize acidizing, fracturing, sand control, and scale control in deepwater wells in extreme environments. View

Deploy flexible, high-capacity stimulation equipment rapidly to meet specific needs for offshore fracturing or acidizing operations. View

Rapidly design a lightweight, modular equipment package optimized for fracturing or acidizing from an offshore supply vessel. View

Designed for jobs from simple acid stimulation to complex hydraulic fracturing operations in the North Sea environment. View

Enhance safety and efficiency of frac fluid delivery and flowback and well testing with services and equipment for rent or purchase.

Automate data delivery from unconventional wells. View

Prepare your well for production with efficient postfracturing services designed to manage frac fluid flowback and well cleanup. View

Install these emergency shutdown valves in line upstream of the testing units to control overpressure, high liquid level, or both. View

Burn natural gas or natural gas vapors with high-efficiency, flexible systems that are easily relocated between sites. View

Control and monitor valves and choke position and operation, and acquire data. View

Prevent hydrate formation and eliminate associated logistics and risk with an alternative to chemical injection into the process stream. View

Remove isolation plug remnants as well as fragments of casing, cement, and other large debris immediately after the fracturing stack. View

Control downstream pressure and fluid volumes during flowback and well testing. View

Remove sand and other small solids from flowback fluids, the production stream, or both, using centrifugal force. View

Separate oil, water, gas, and solids into individual streams for more accurate measurement and discharge control. View

Plan contingencies, manage certifications, and deliver equipment required to enhance safety in flowback and production operations. View

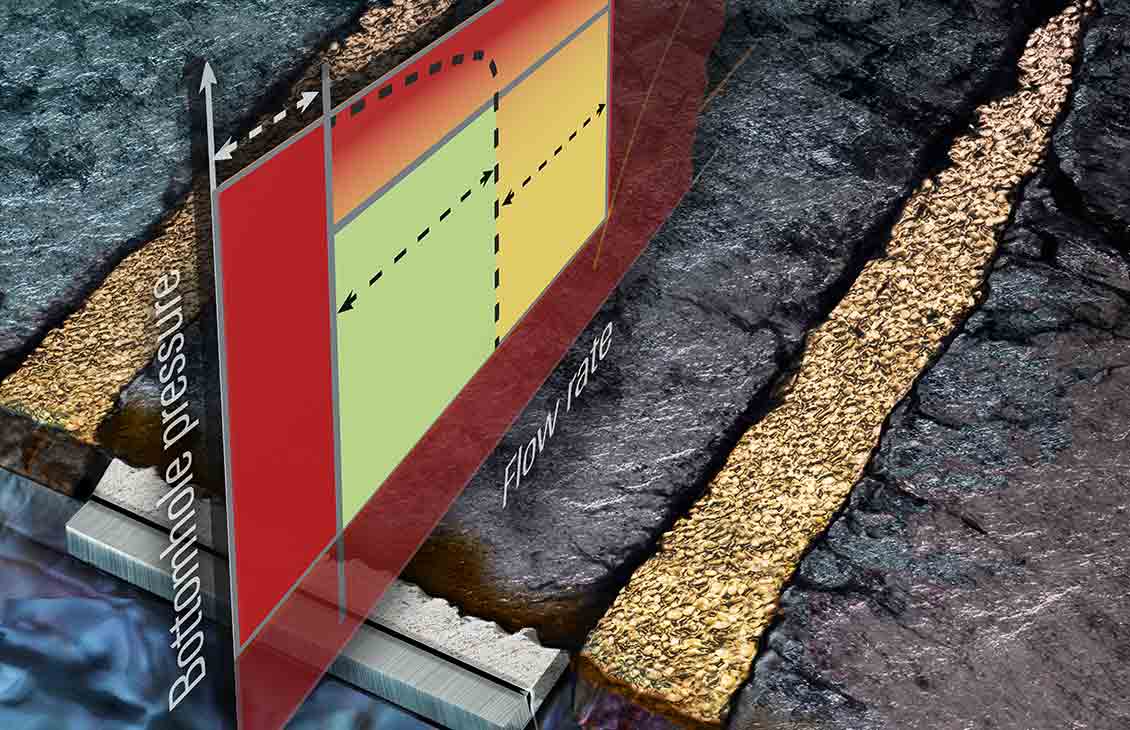

Optimize productivity in fractured wells with integrated modeling, monitoring, and control. View

Protect the tubing spool or CT string and minimize surface risks during high-volume, high-pressure, and high-rate fracturing operations.

Protect a Type C tubing spool from high pressure and erosion while extending the tubing spool pressure rating for hydraulic fracturing. View

Protect the CT string from abrasive fracturing fluid in pinpoint or CT fracturing operations. View

Hold pressures up to 15,000 psi to provide fullbore access and an alternative to the use of bore isolation tools. View

Hold pressures up to 15,000 psi and enhance safety and efficiency with an alternative to bore isolation tools. View

Save time, reduce costs, and mitigate risk to the frac tree during high-pressure fracturing treatments. View

Maximize total life cycle cost savings for flow iron fittings, plug valves, pup joints, and swivels used in hydraulic fracturing, cementing, well testing, and flowback.

Manage total life cycle costs for hydraulic fracturing, cementing, well testing, and flowback. View

Manage total life cycle costs for hydraulic fracturing, cementing, well testing, and flowback. View

Manage total life cycle costs for hydraulic fracturing, cementing, well testing, and flowback. View

Manage total life cycle costs for hydraulic fracturing, cementing, well testing, and flowback. View