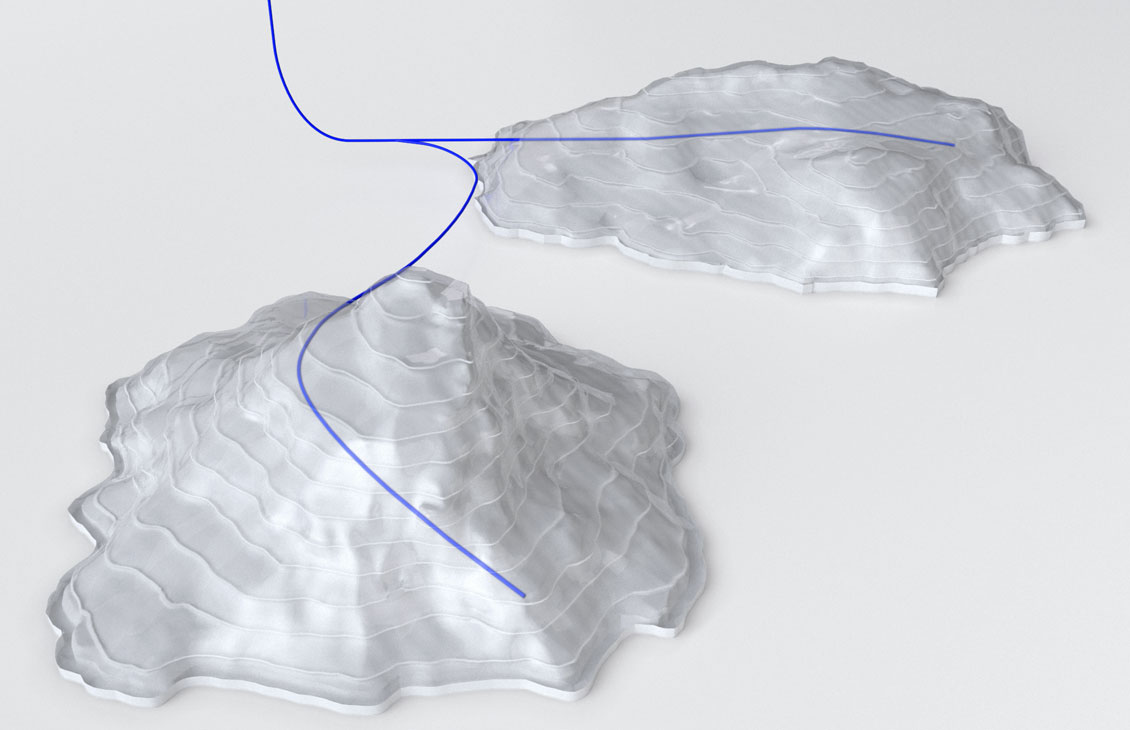

Video Case Study: Vår Energi Avoids Constructing Two New Subsea Wells

Retrofitting two wells as multilaterals avoided adding infrastructure, reducing our customer’s GHG emissions.

Collaborate to drive high performance sustainably for low carbon impact

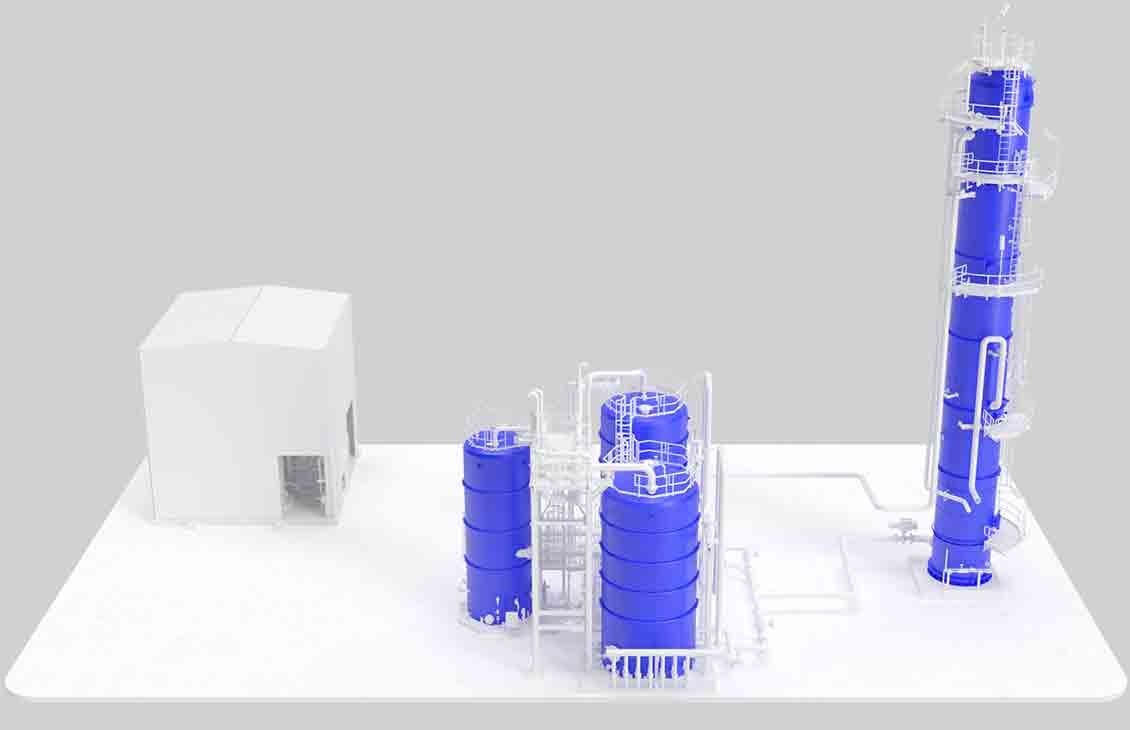

While individual technologies may meaningfully reduce your environmental impact, the biggest impacts occur when entire projects are planned collaboratively. Early engagement is key. When we work together to understand the project drivers early, we can help assess the relative impact of the available options. Our teams then design the solution that best fits your project’s needs. This way, the right technology is selected and deployed the right way to realize maximum benefits—for your business and a balanced planet.

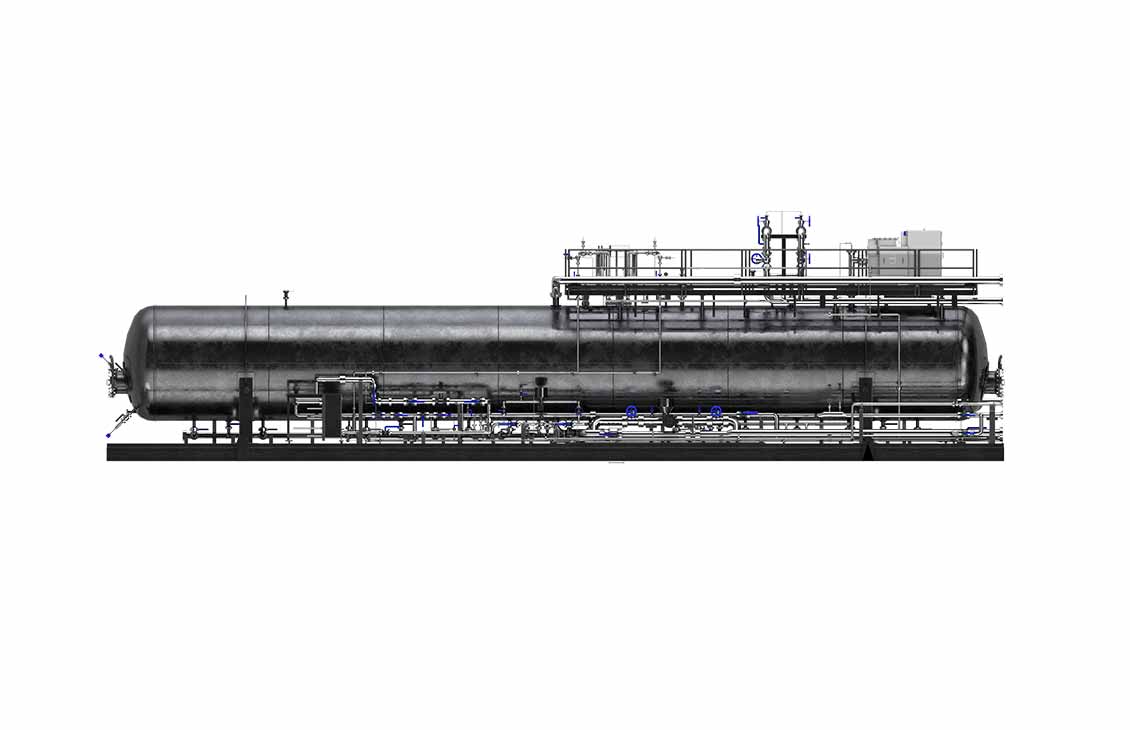

In production operations, our collaboration with customers has driven highly complex and differentiated subsea and completions solutions that have avoided thousands of metric tons of CO2 and have contributed to a large reduction in energy consumption. The results create maximum value while achieving cost-efficient production and lower carbon impact.

Watch how we helped Vår Energi avoid additional infrastructure for two new subsea wells and reduced greenhouse gas (GHG) emissions using rapid multilateral systems.

Separate acid gases from produced natural gas without chemicals. View

Natural gas sweetening via H2S, H2O, and bulk CO2 removal. View

Use both AC and DC power to significantly improve processing vs. conventional AC electrostatic technologies. View

Increase reserves access with laterals that enable well reentry and expansion while minimizing surface costs. View

Eliminate requirements for upstream separation or antisurge systems. View

Maximize oil and gas flow through hydraulic fractures by creating infinite-conductivity channels in your proppant pack. View

Eliminate milling with a robust frac plug that isolates reliably and then dissolves rapidly to enable fullbore production. View

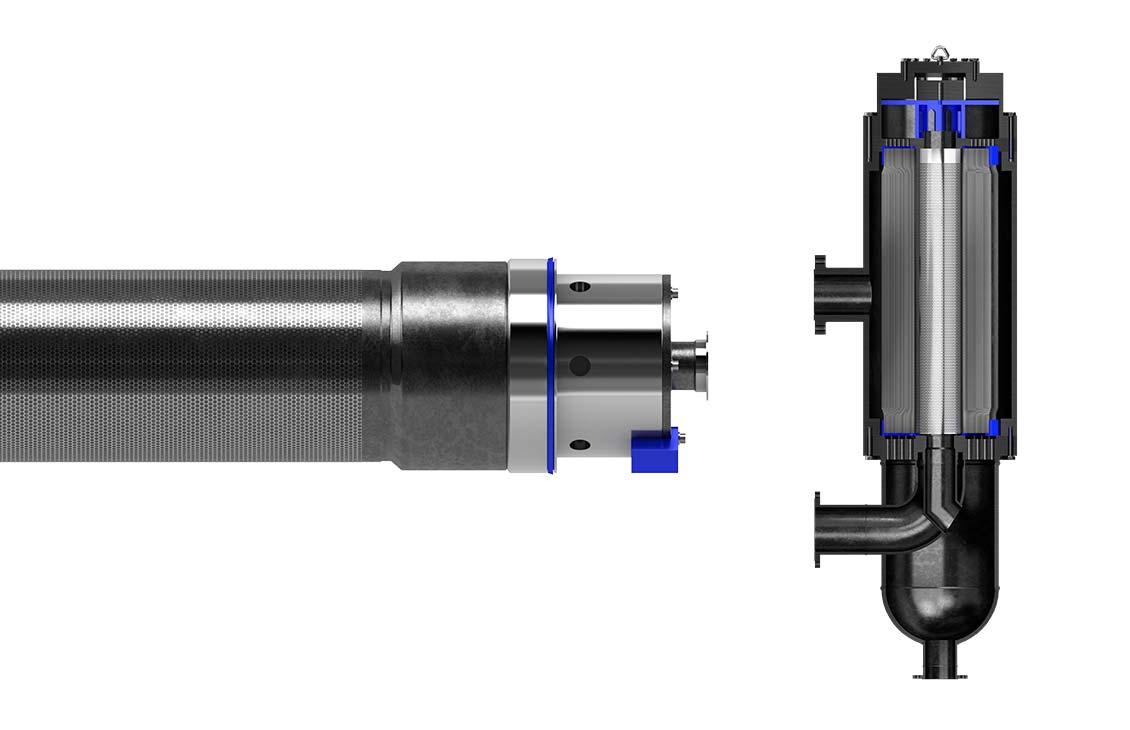

Increase ESP reliability and lifetime with a cooler, more robust high-efficiency motor. View

ESP Permanent magnet motors have power efficiency, power factor, and power density and help lower electricity consumption. View

Handles up to 90% gas volume fraction; used for zero-flaring well tests, well cleanup, and production boosting. View

Handle GVFs up to 100% mechanically and fluid viscosities from 1 to 4,000 cP at startup. View

Convert H2S in gas streams to solid sulfur ready for agriculture or disposal. View