Tech Paper Tubing Straddle System to Restore Oil Production Using Digital Slickline Conveyance: A Case Study

Rigless tubing repair proves to be a viable quick solution to maintain well production until a workover rig becomes available.

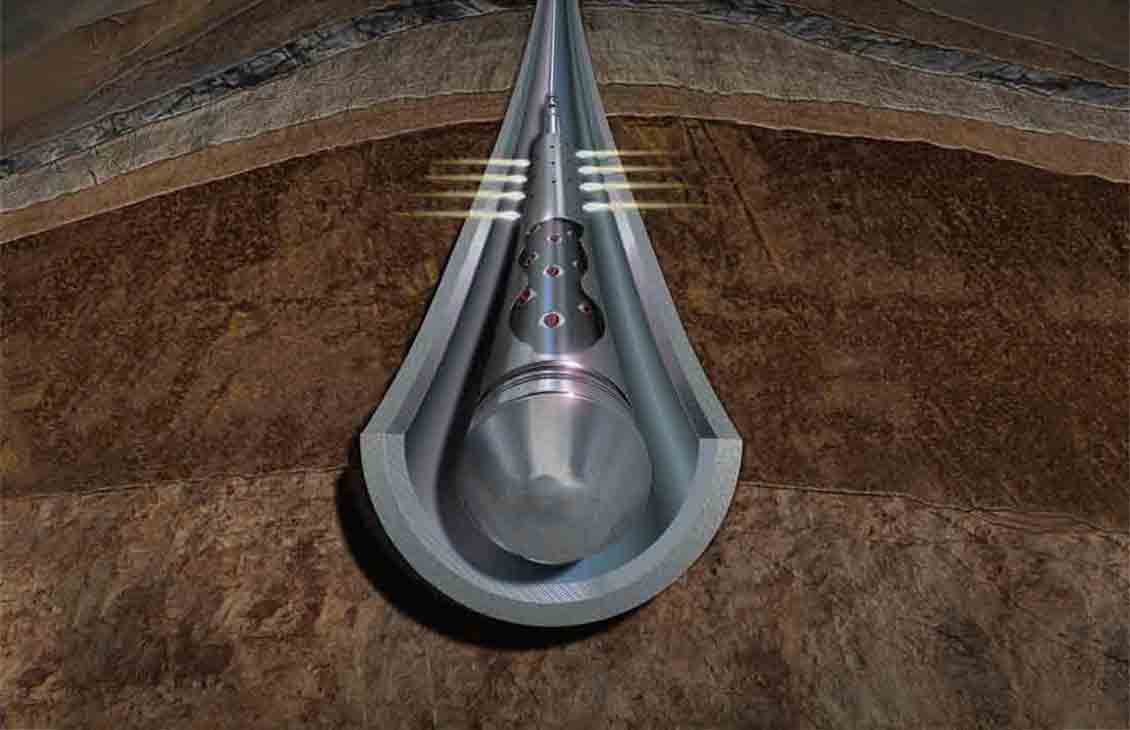

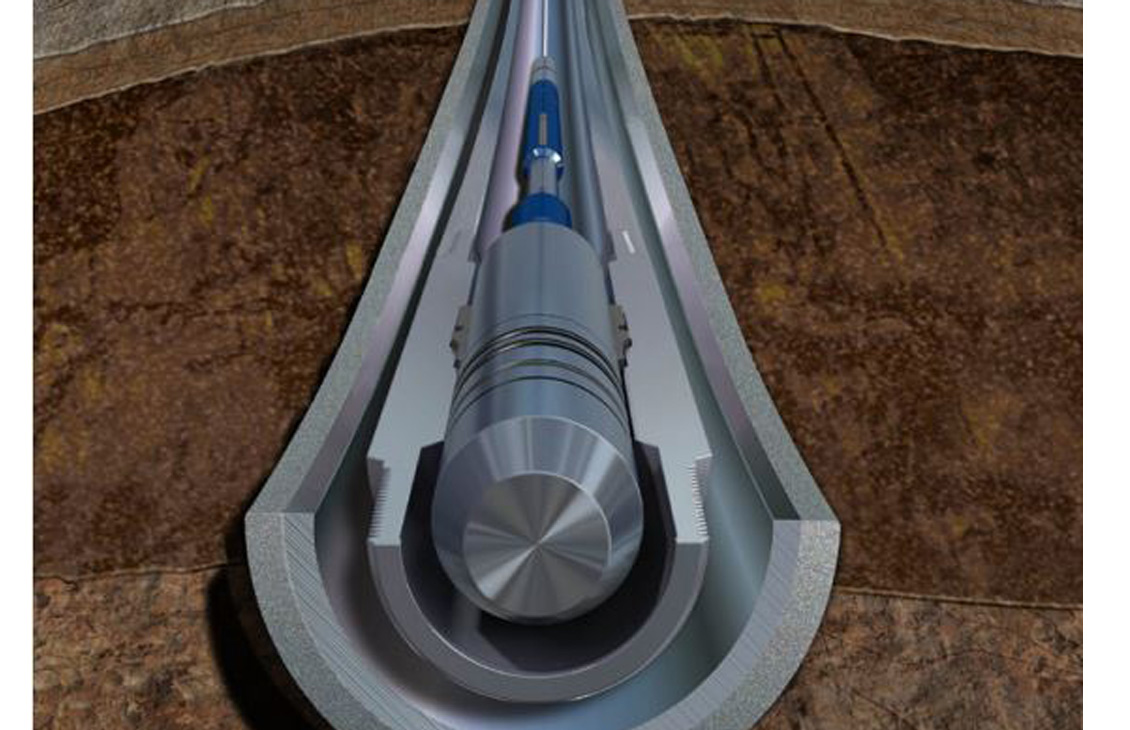

Digital slickline services

LIVE digital slickline services enable performing a wider range of slickline activities with control and certainty.

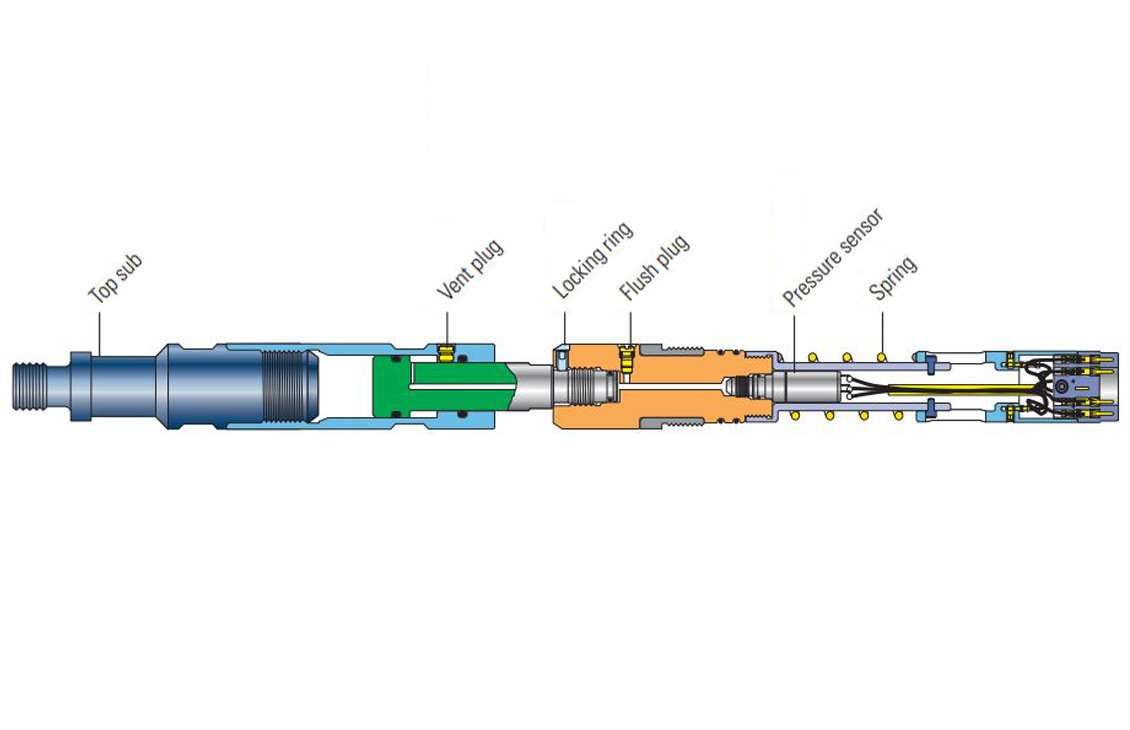

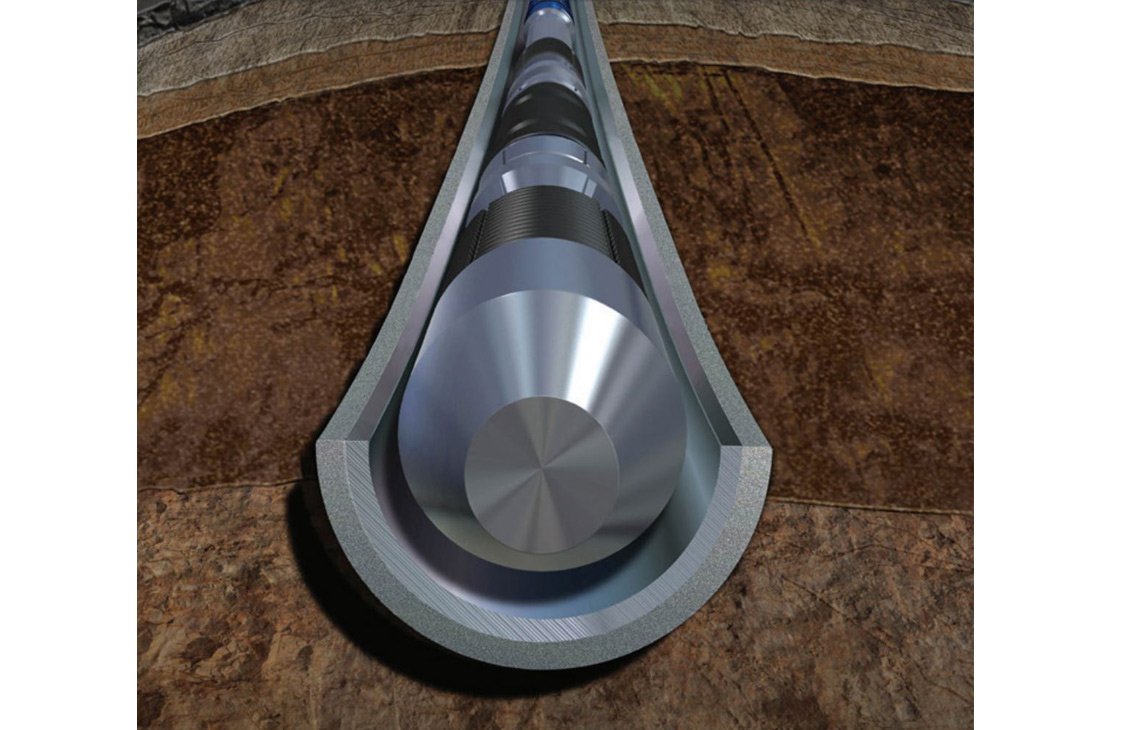

The integral coating of the cable enables two-way digital communication during deployment using a standard slickline unit and pressure control equipment. Sensors in the downhole digital cartridge measure cable tension, detect shock and well deviation, and monitor internal temperature.

The depth correlation capabilities of LIVE services confirm that operations are on depth and provide the exact position of the downhole tool at all times. With continuous depth correlation, your operations can be adapted in real time and the success of the job can be confirmed before pulling out of the hole.

Real-time downhole measurements that improve reservoir performance.

Enhance the quality and safety of mechanical operations with accurate depth measurement and downhole monitoring. View

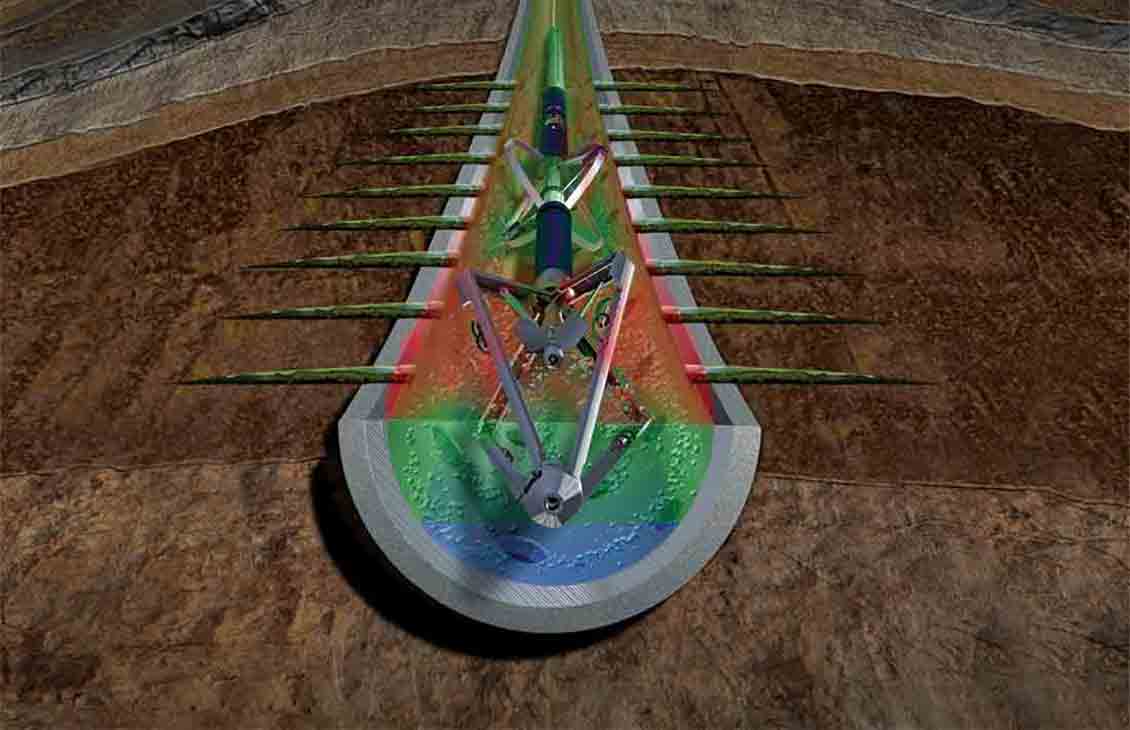

Perforate, punch tubing, and cut for pipe recovery—on depth and in real time. View

Run real-time production logs with the efficiency of slickline across a range of wellbore environments. View

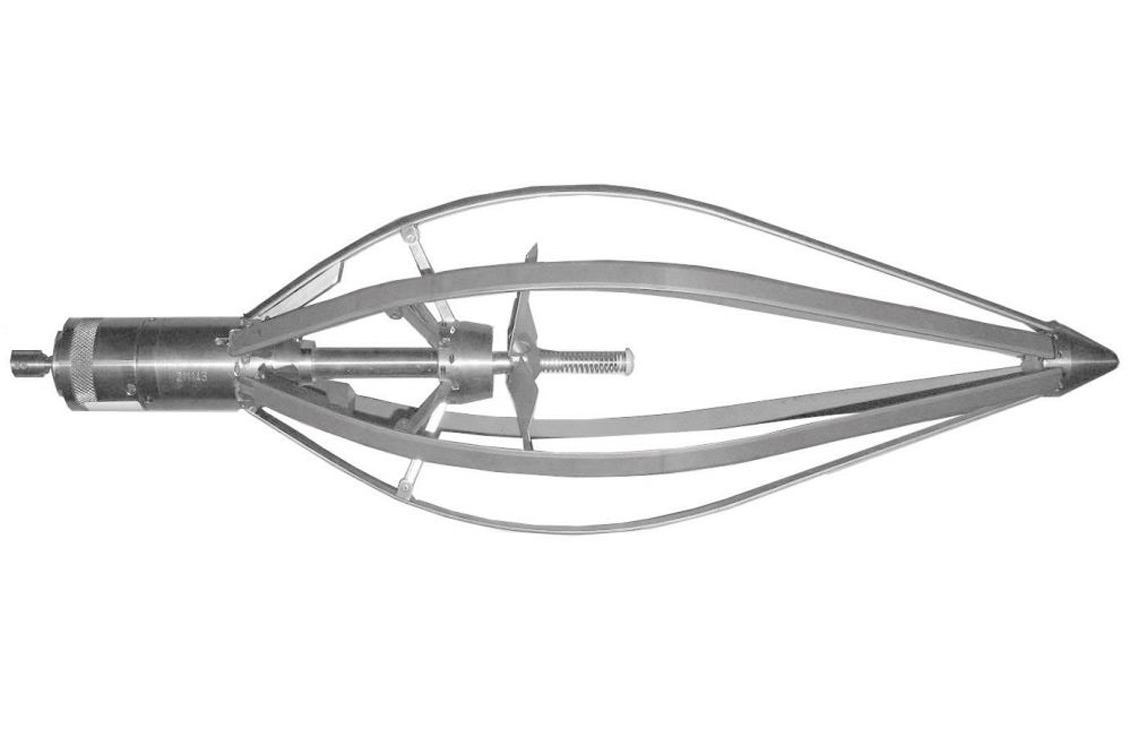

Components exclusive to the mechanical elements of LIVE services.

Inform wellsite decision making and optimize reservoir management and production in mature fields. View

Take full control of arming, firing, aborting, and rearming. View

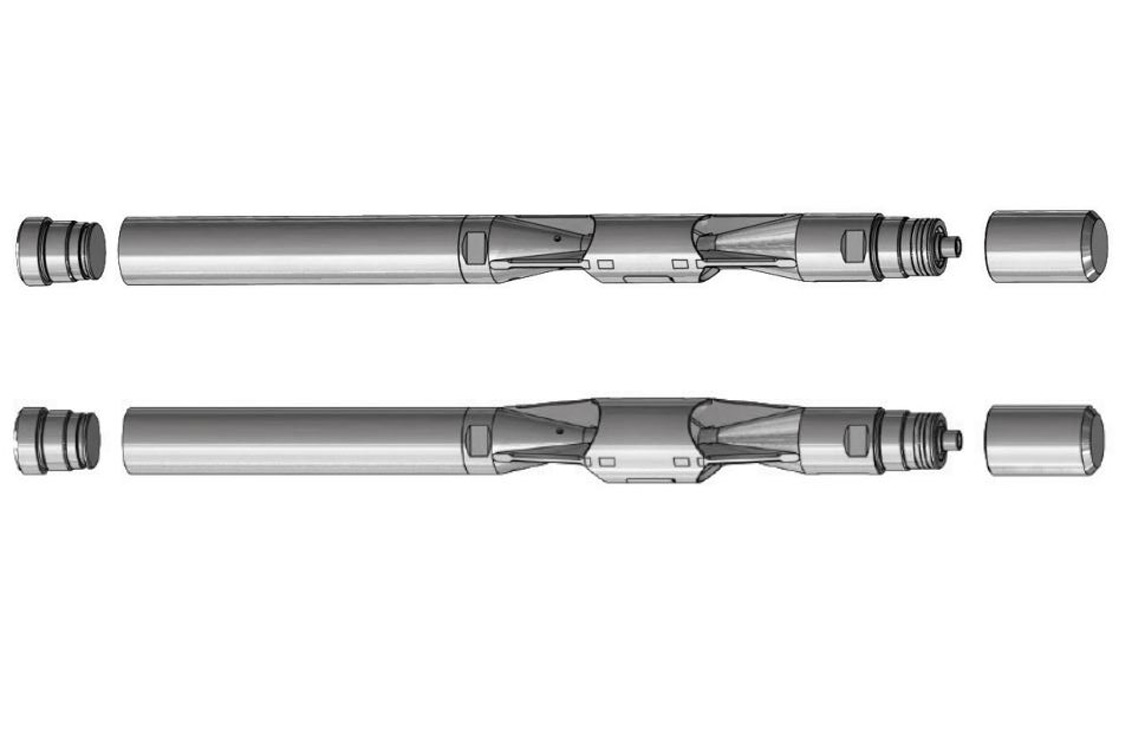

Enable controlled separation of the toolstring head and tool assembly, leaving a standard internal and external fishing profile downhole. View

Electrically release based on LIVE Act services tension measurements at the head of the toolstring. View

Combine with D-Set tool for simple mechanical jarring of the standard digital slickline toolstring. View

Control this industry-compatible electrohydraulic, battery-powered setting device from surface. View

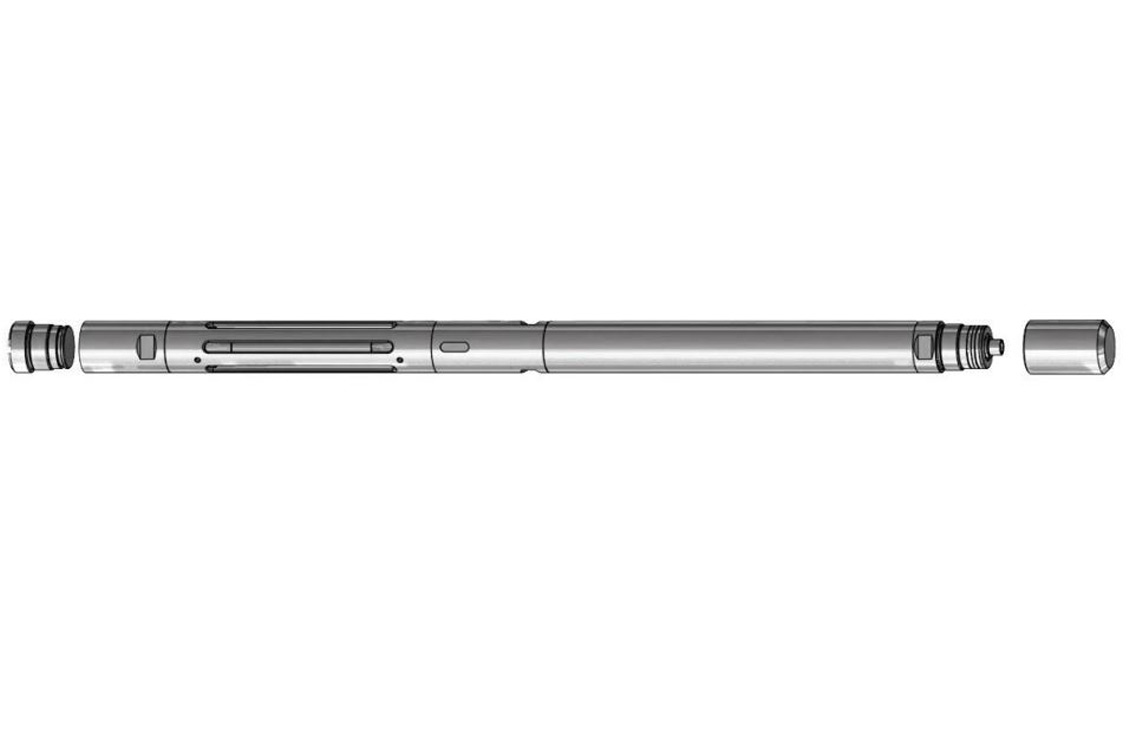

Provide flow measurement in casing or tubing by combining a mechanical spinner with the digital flowmeter cartridge. View

Deliver in-casing flow measurement using a mechanical spinner section combinable with a digital flowmeter cartridge. View

Acquire secondary spinner measurements in high fluid velocities. View

Control acquisition by the production logging tools downhole. View

Combine three key production logging sensors in one compact, reliable package. View