Video Minimize Well Construction CO2 Footprint

Decarbonize drilling operations with proven impact-reducing technologies.

Reduce emissions on the rig and from transport operations and use consumables with low embodied carbon

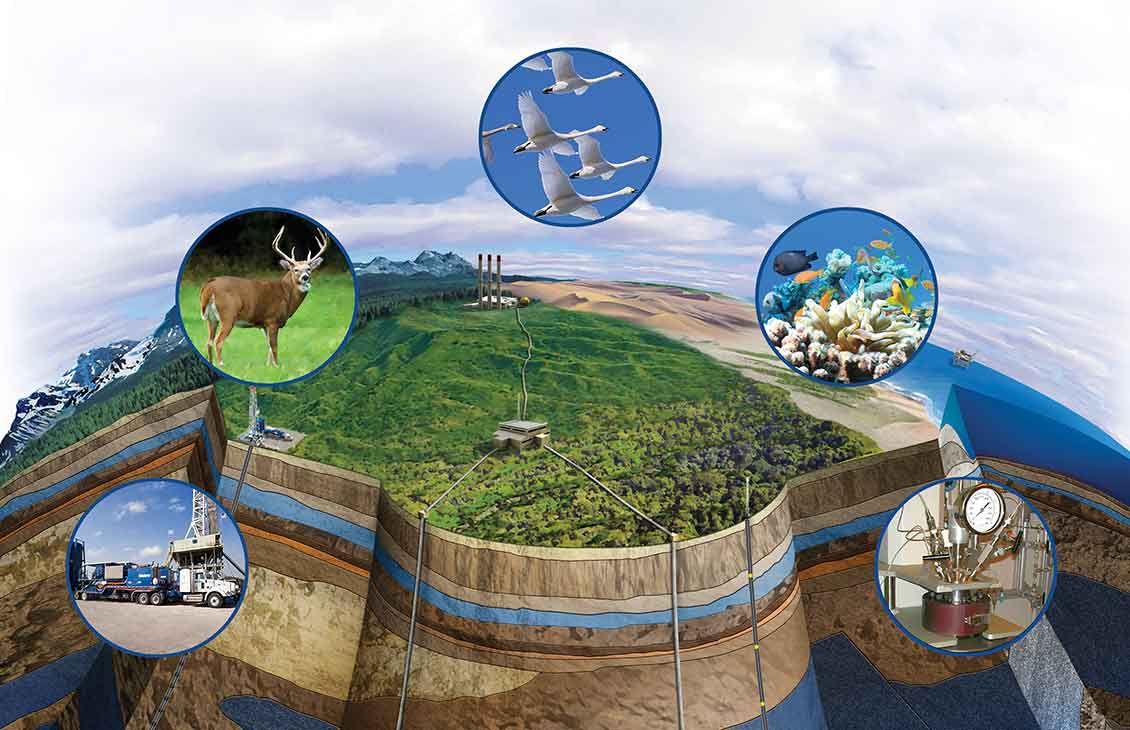

No matter where you are in the well construction process, offshore or onshore, we'll help you find ways to reduce CO2 emissions while maximizing the value of operations. We do this by understanding your sustainability goals and matching them with our technologies that quantifiably reduce footprint. These proven solutions help you make more informed decisions in decarbonizing your operations while driving superior business results.

Increase efficiency and reduce your energy consumption. Improving operational efficiency reduces fuel burned by the rig per well drilled. This consequently drives down emissions. We've quantified the impact of our most differentiated oil and gas technologies that have been proved to construct wells faster with less fuel consumption and lower emissions—even in the most challenging environments.

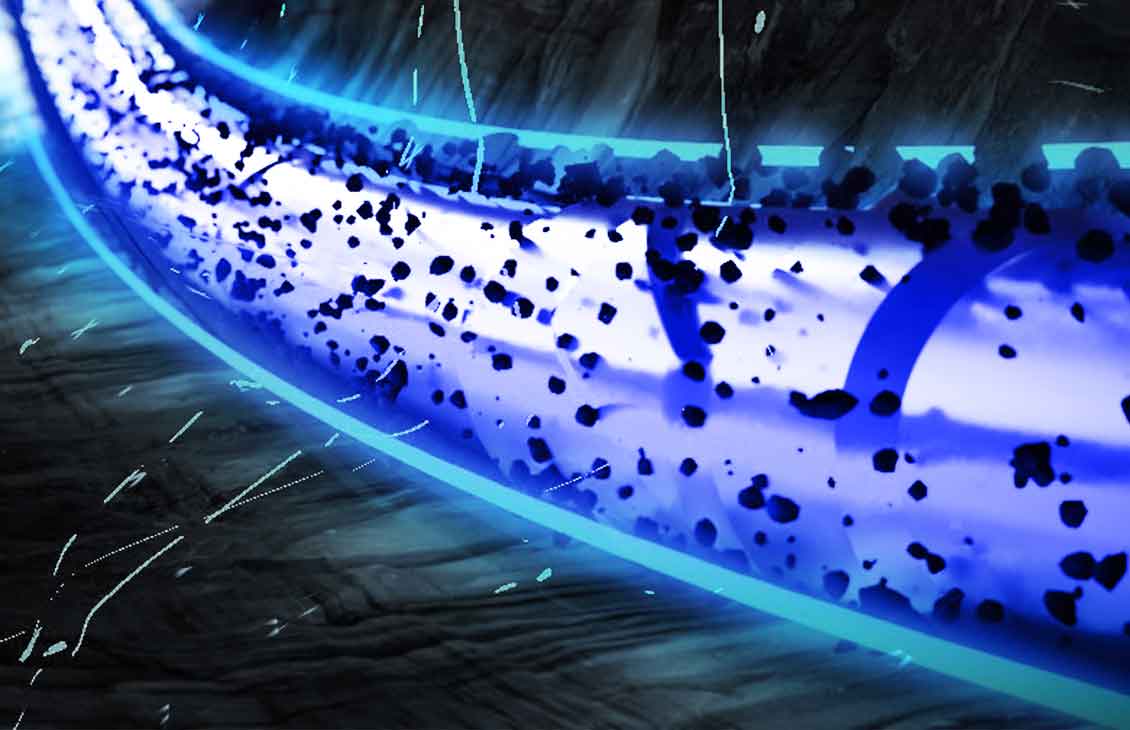

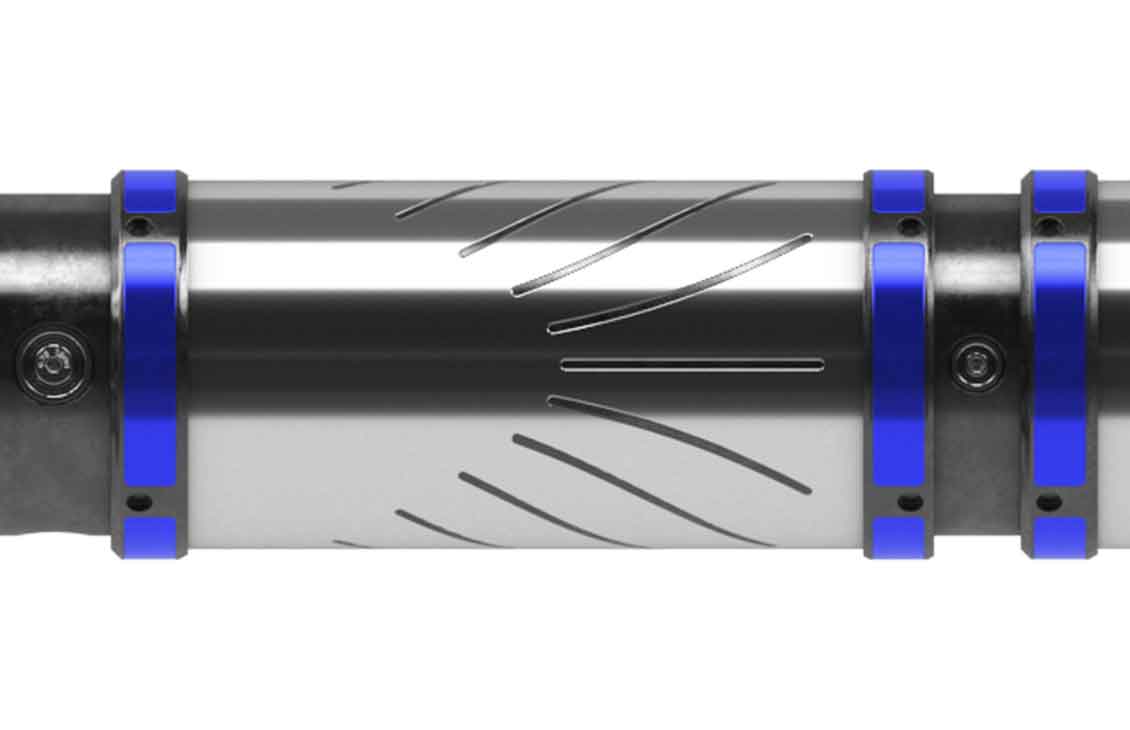

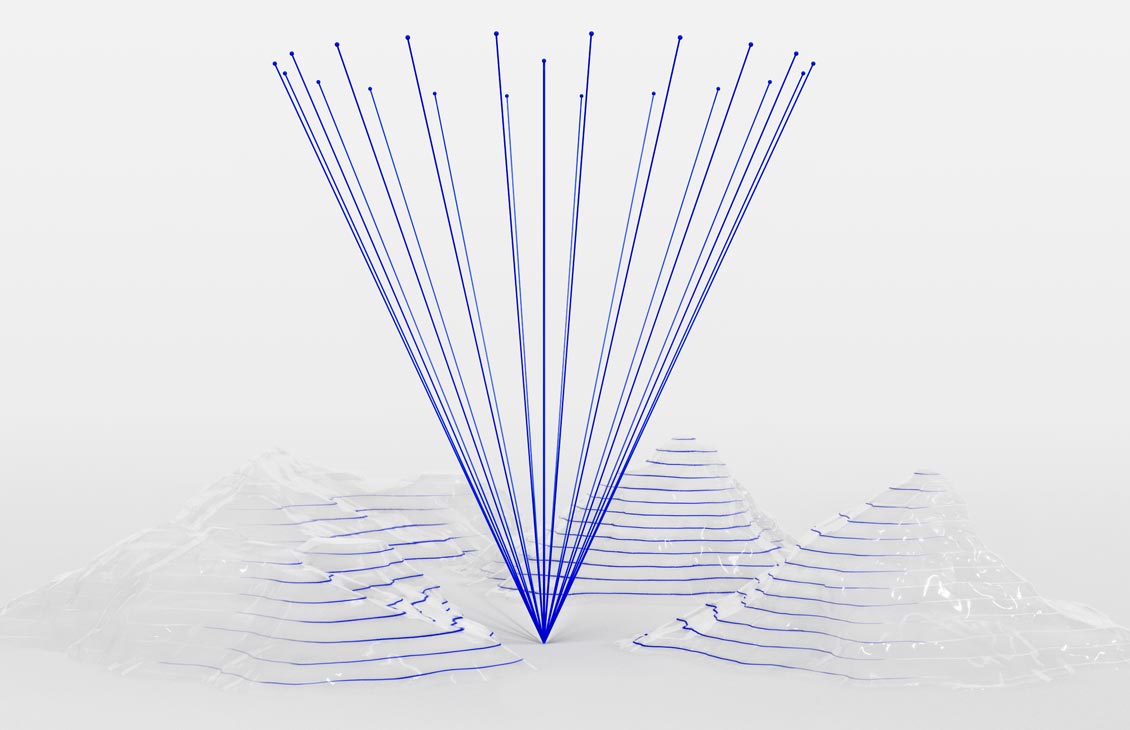

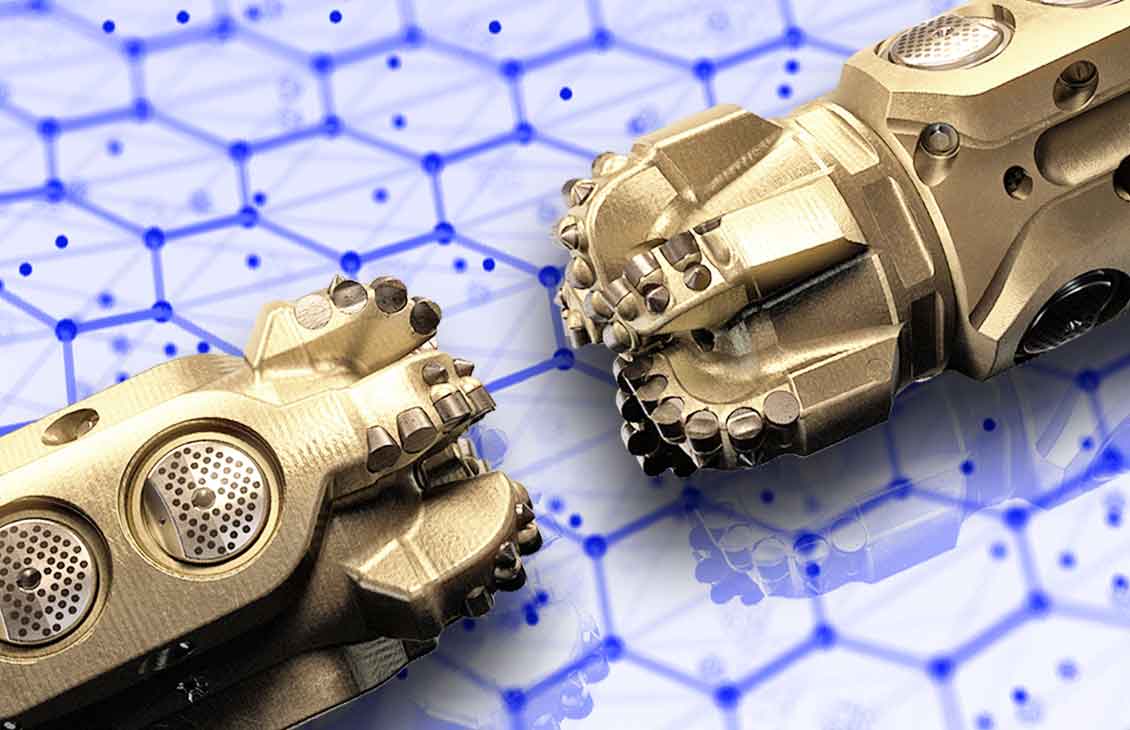

Our commercially available technologies that increase efficiency and reduce energy consumption include industry-first rotary steerable innovations such as NeoSteer at-bit steerable systems (ABSS), which minimize trips to drill curve and lateral sections, and Geosphere 360 3D reservoir mapping-while-drilling service, which maximizes reservoir contact in every well. These drilling efficiency enablers are supported by subsurface evaluation technologies such as Optiq Seismic fiber-optic borehole seismic solution, which virtually eliminates emissions related to borehole seismic acquisition. And our intelligent power management solution is a comprehensive system that optimizes rig power generation, reducing fuel consumption and emissions per kW.h generated, and offers a path to near-zero rig emissions by using hydrogen.

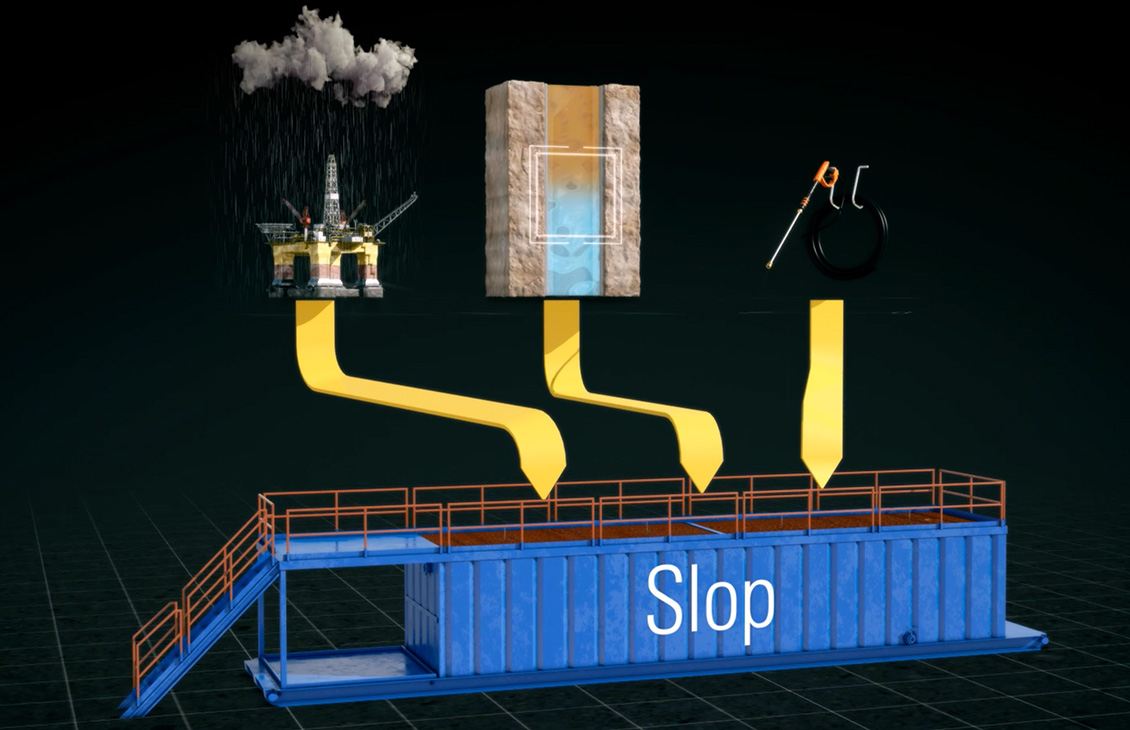

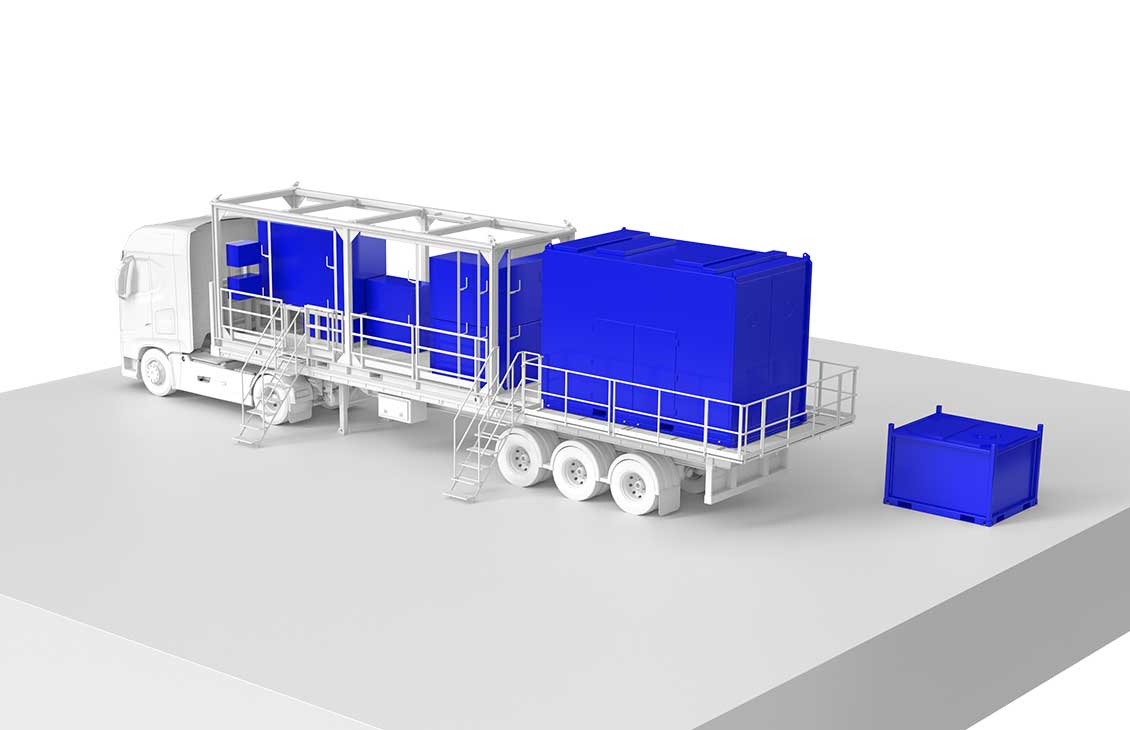

Handle less waste and make fewer trips to and from the rig. Cut your carbon footprint even more by reducing the amount of waste you process and transport. Our ATC automatic tank-cleaning technology and ENVIROUNIT offshore slop water treatment system minimize offshore waste generation and reduce emissions by requiring fewer supply boat trips compared with onshore waste handling.

Adopt low-carbon technologies that reduce embodied emissions in consumables. Additional Scope 3 emissions reductions are also achievable when you use fluids and products that produce less CO2e emissions during their design and manufacturing compared with traditional technology. Our impact-reducing technologies include cementing and fluid solutions, and this is just the start of our journey.

Transition to digital solutions for more consistency and higher-performing operations. We believe digital solutions and automation are key enablers that will unlock new levels of performance and maximize emissions reductions. For example, our Performance Live digitally connected service enables an ecosystem that delivers more consistent and higher-performing operations. These solutions can eliminate manual tasks, reduce crew size requirements, and quantifiably improve performance and reduce GHG emissions.

Reduce well construction emissions through planning, monitoring, and innovation. Our end-to-end approach to drilling emissions management can help you gain greater long-term impacts. See how our teams can design a rig- and operation-specific emissions monitoring and reduction approach using cost-effective solutions.

Mitigate the risk of CO2 degradation and leakage when cementing new CO2 injection wells or plugging and abandoning existing injection or production wells. View

Ensure zonal integrity for the life of the well with a flexible cement system that, if damaged, repairs itself on contact with oil or gas. View

Reduce offshore drilling waste stream by up to 90%, reduce trips to shore, lower emissions and fuel use. View

Minimize HSE risks, waste generation, and emissions. View

Leverage increased abrasion resistance, higher DLS for tighter curves, and better directional control while lowering emissions. View

Achieve real-time, high-definition wellbore architecture—from tophole to TD. View

Tailor a solution to meet your objectives for fuel efficiency, emissions, and engine life. View

Now you can drill with real-time insights on fluid volumes, bodies, faults, and lithology—at reservoir scale. View

Improve performance and consistency using a digital ecosystem enabling access to expertise anytime and anywhere. View

Experience your reservoir like never before. View

Improve efficiency of borehole seismic operations by eliminating the need for a dedicated seismic descent. View

Integrated steering and cutting structure technology for unprecedented DLS capability, durability, and ROP. View

Explore technologies and solutions that can help achieve zero flaring or minimize its emissions.