Case Study Operator Expands Operating Envelope Using Improved Packers

Customizable packers save 1–2 days per multizone completion and enable operator to expand operating envelope

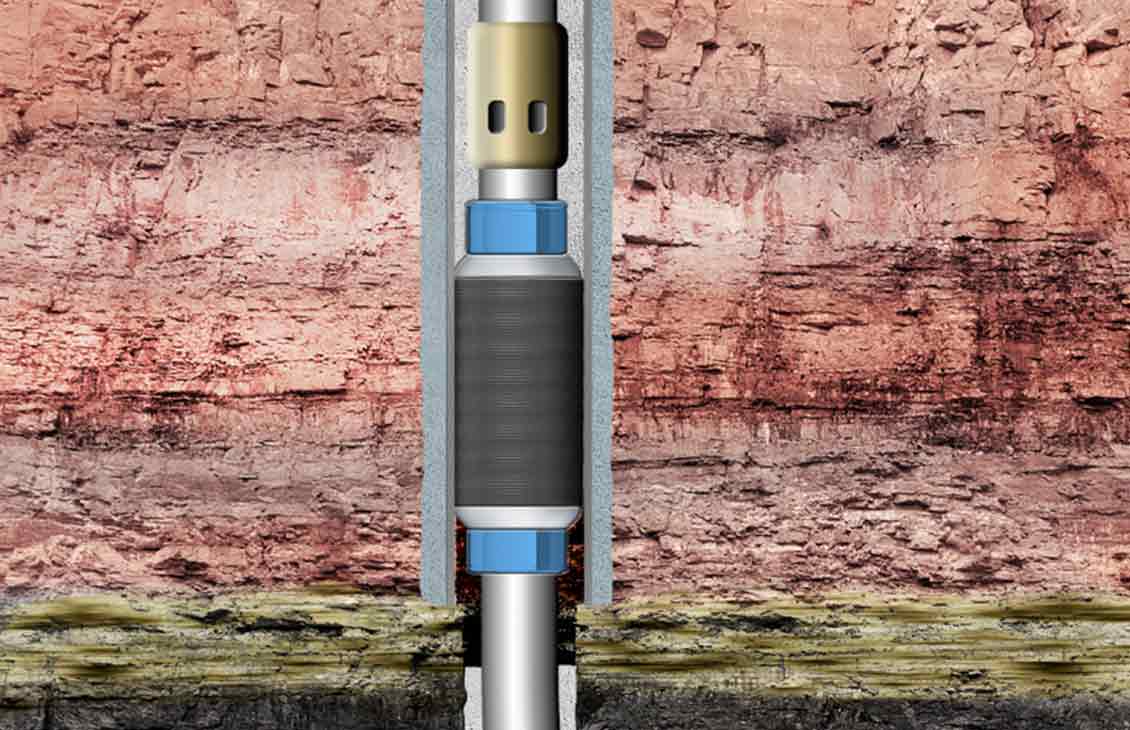

Manage downhole risks with robust sealing technology

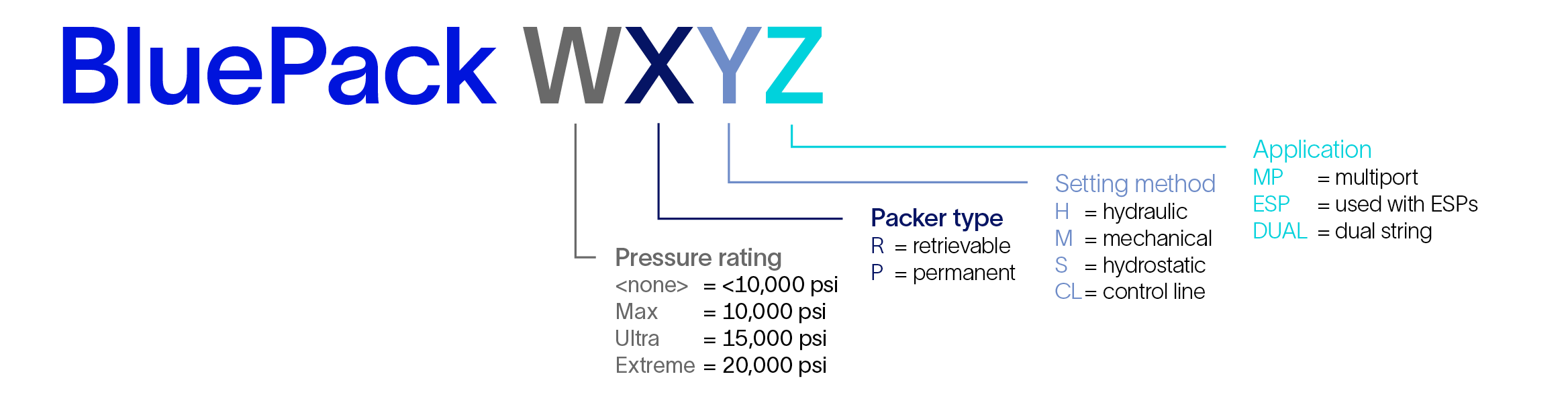

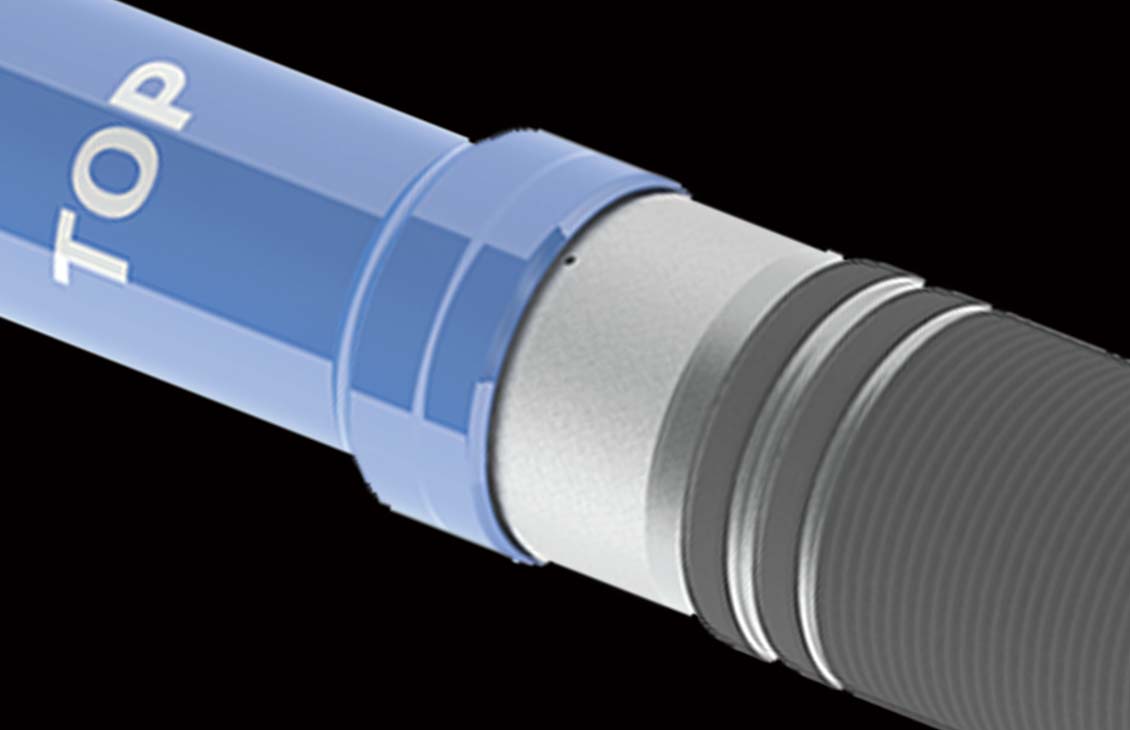

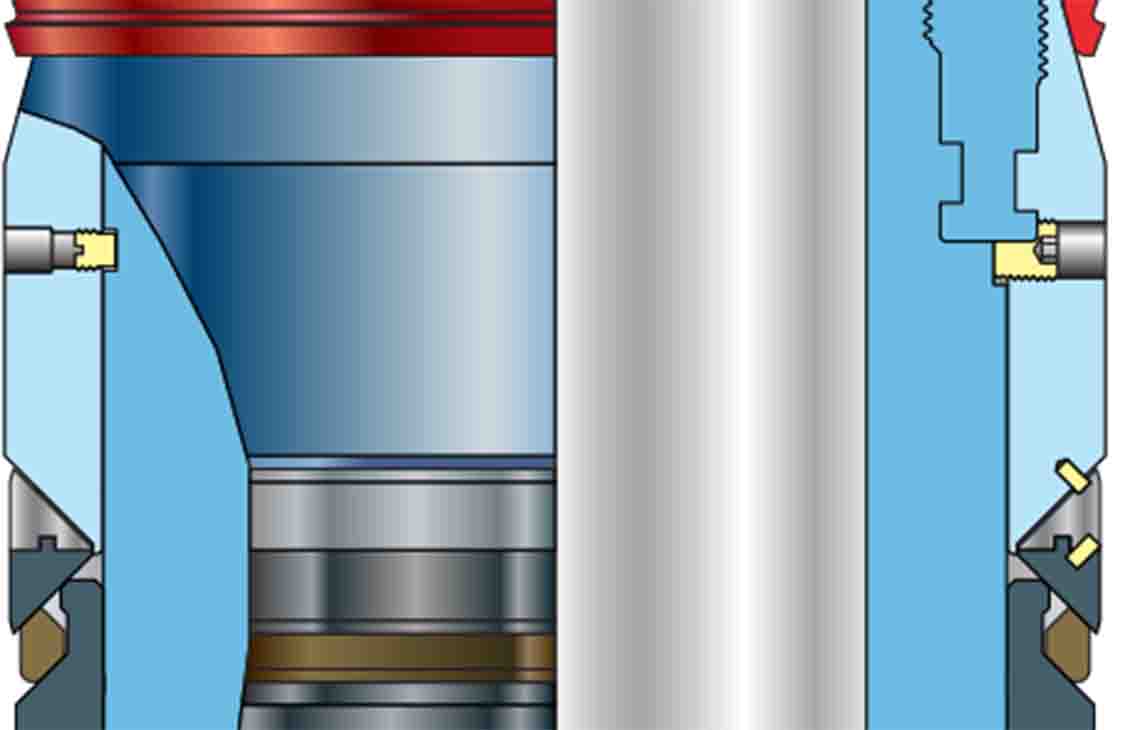

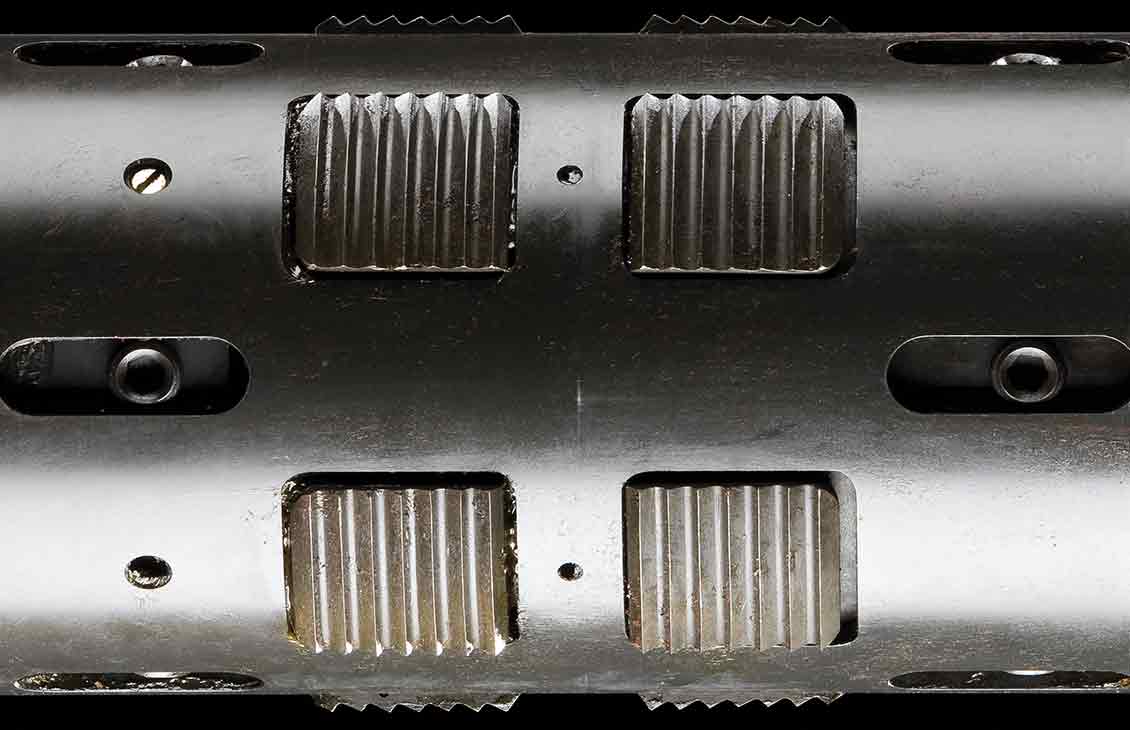

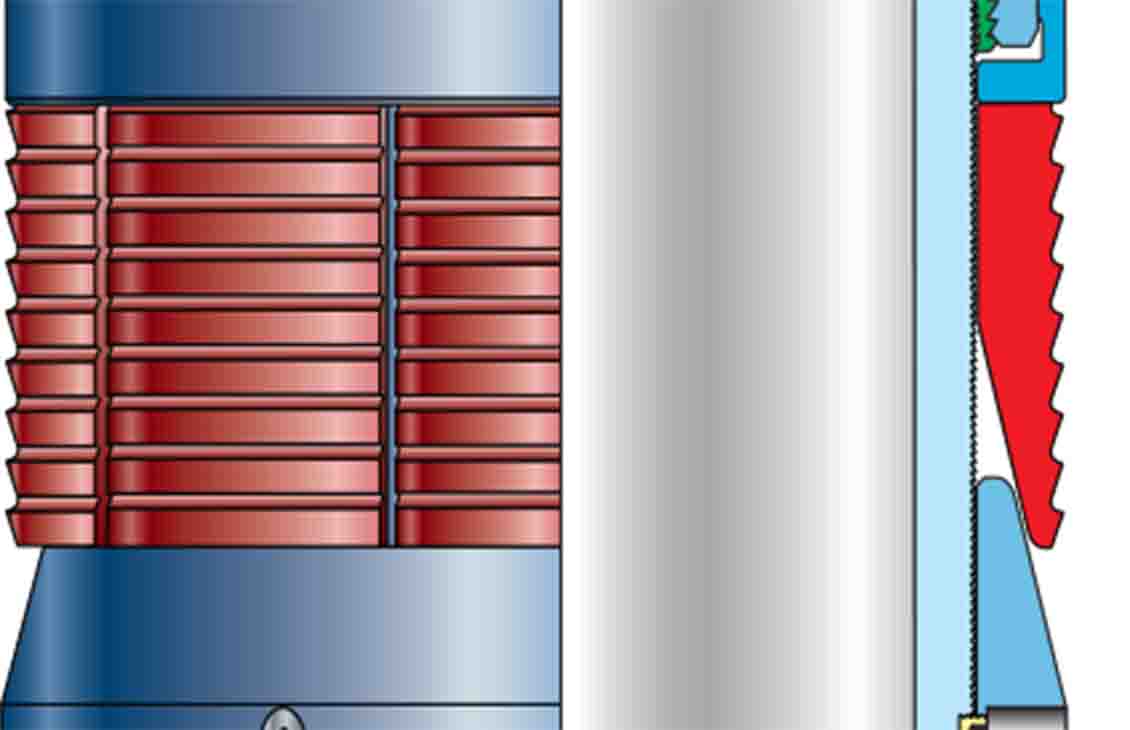

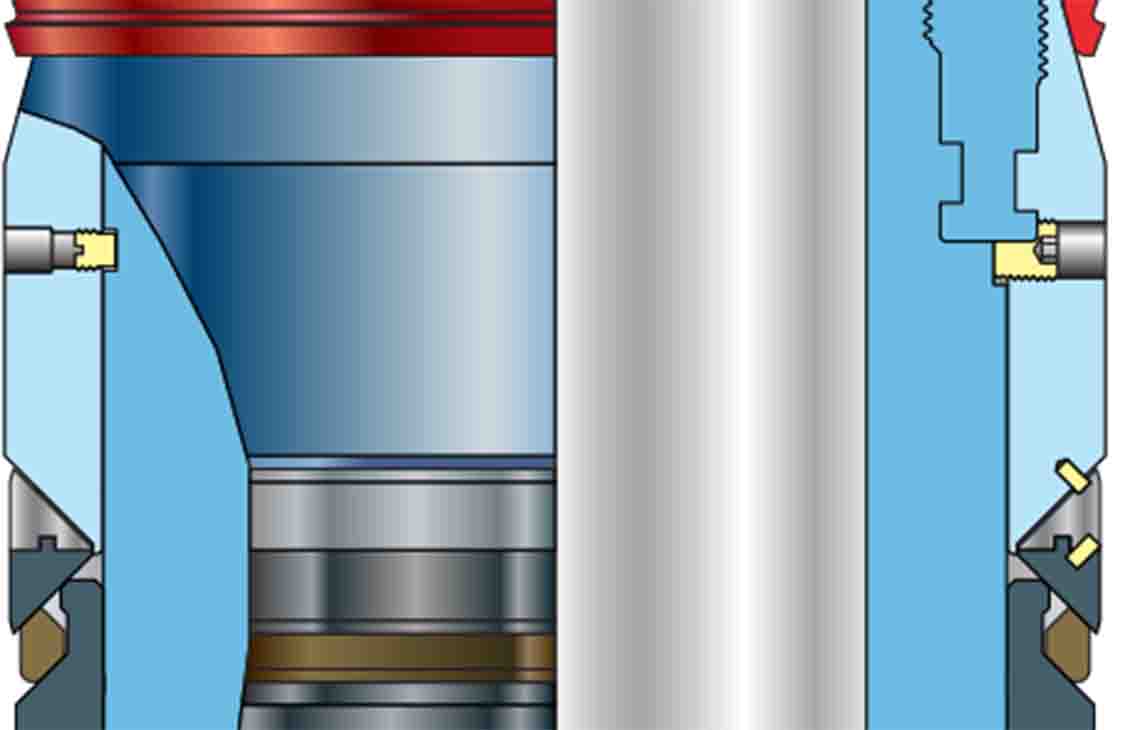

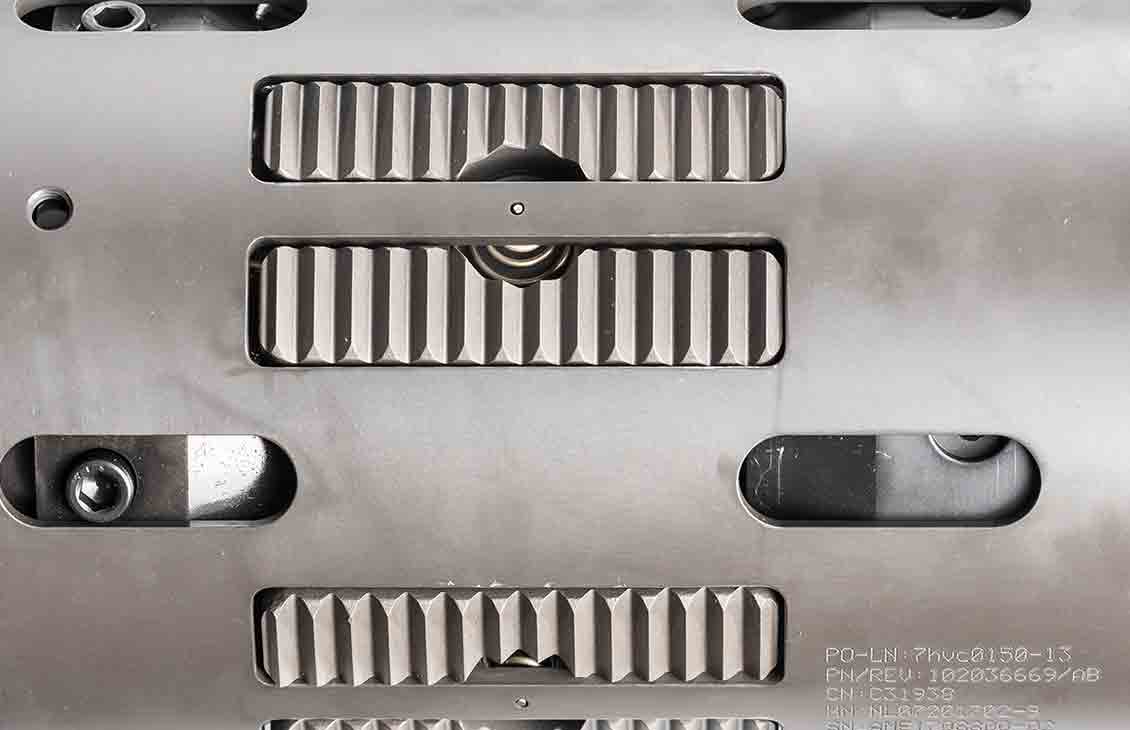

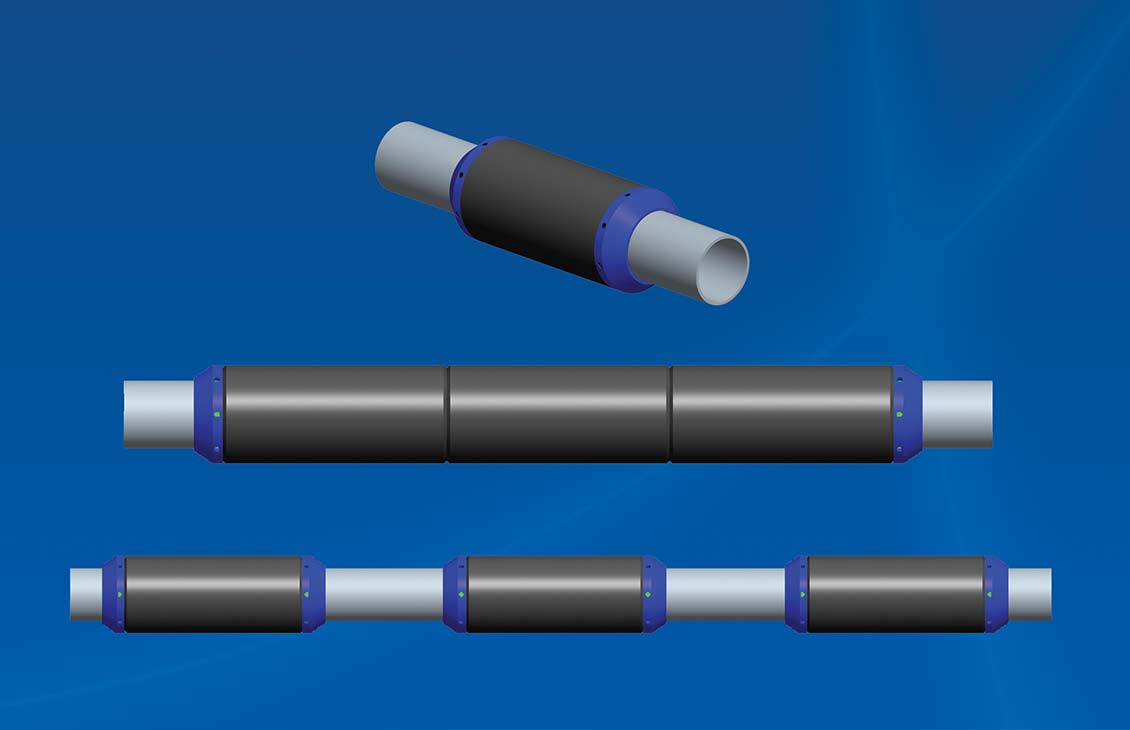

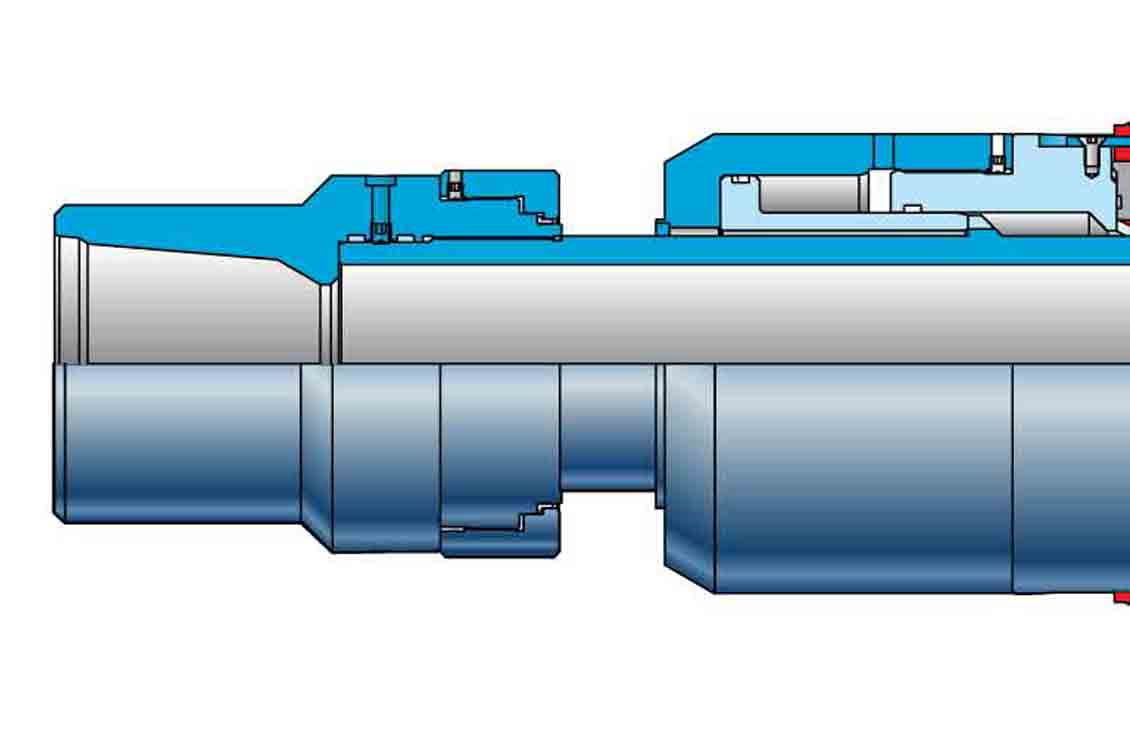

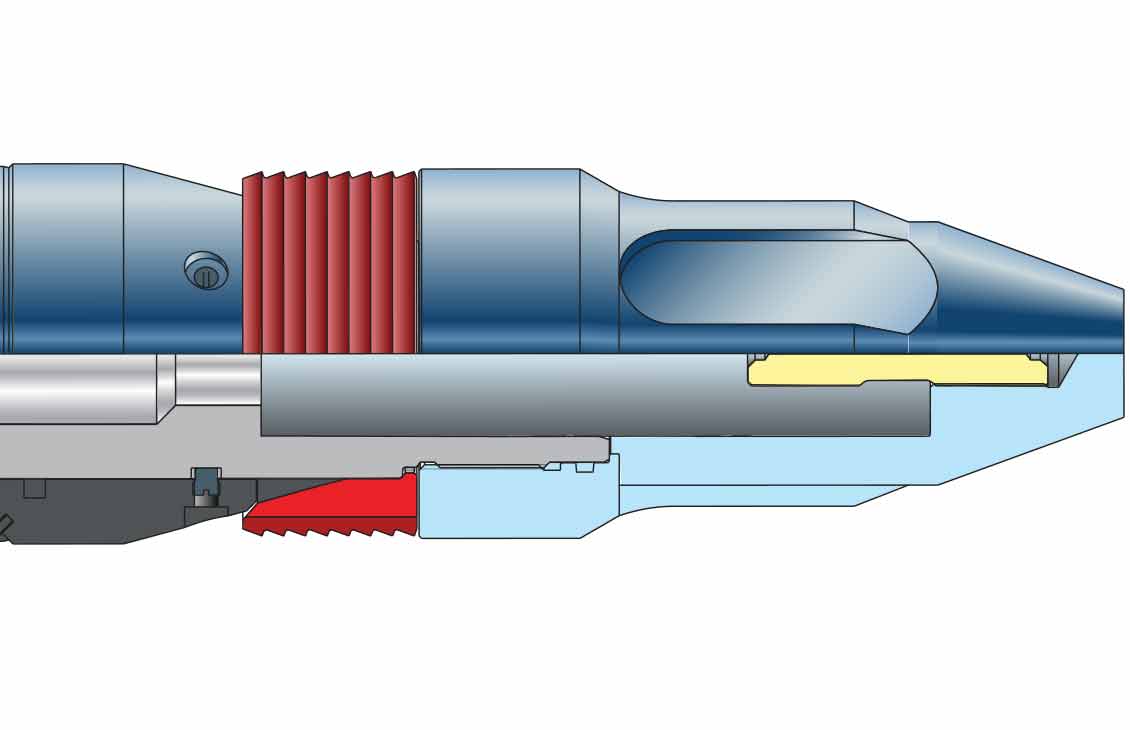

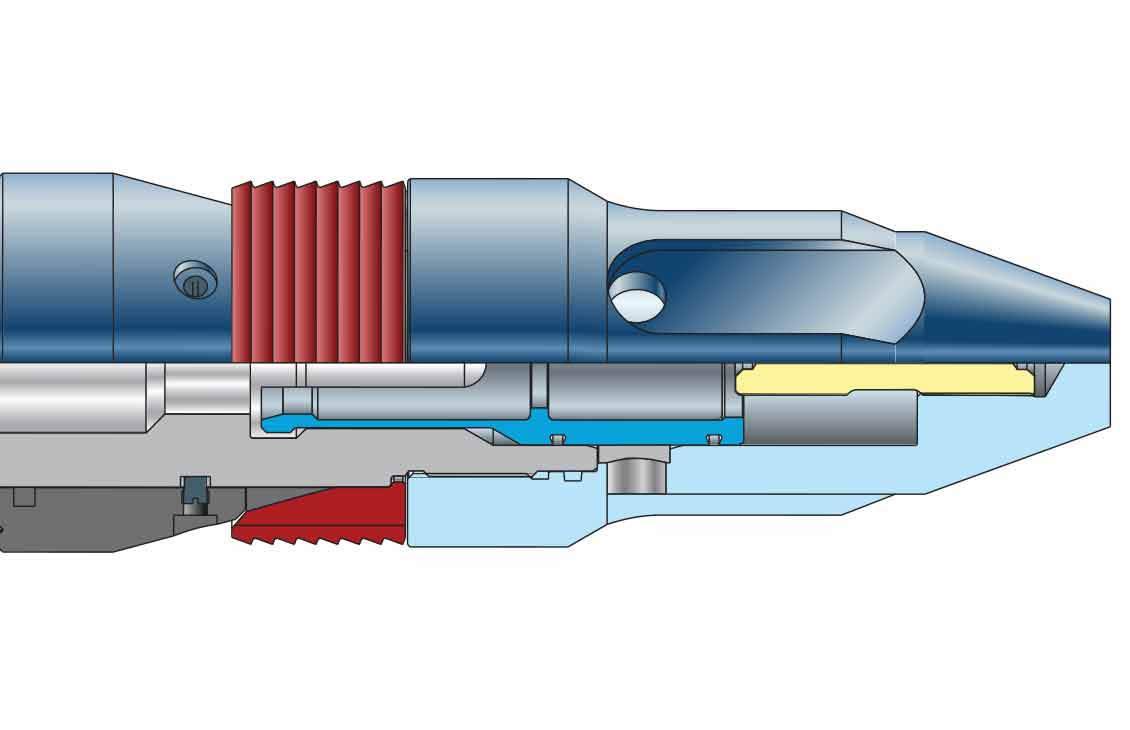

The modular architecture of our BluePack packer family simplifies engineering designs. Select the packer that's best suited for your well environment while configuring certain components and subassemblies based on the specific needs or challenges of the well. For example, you might customize the elastomer based on the chemical properties of the fluids that will be in the well.

This standardization not only leads to time and cost savings, it also improves operations by ensuring your employees are trained on a standardized deployment methodology.

Meet your requirements for noncomplex applications with low to medium pressure demands—with technical flexibility to match the way you work.

Save rig time with a single-trip sand control solution for single- and multizone completions. View

Install this economical packer for isolation in production or water injection wells to manage up to 5,000-psi pressure differentials. View

Isolate fluids and pressures up to 7,000 psi with an economical hydraulically set, straight-pull shear-release retrievable packer. View

Save rig time by running the QL packer as a production packer, gravel-pack packer, or sump packer in standard or H2S service. View

Achieve fast installation with this robust high-pressure production or isolation packer. View

Streamline running and setting in deviated wells with single-trip gravel-pack completions, and use any QUANTUM packer accessories. View

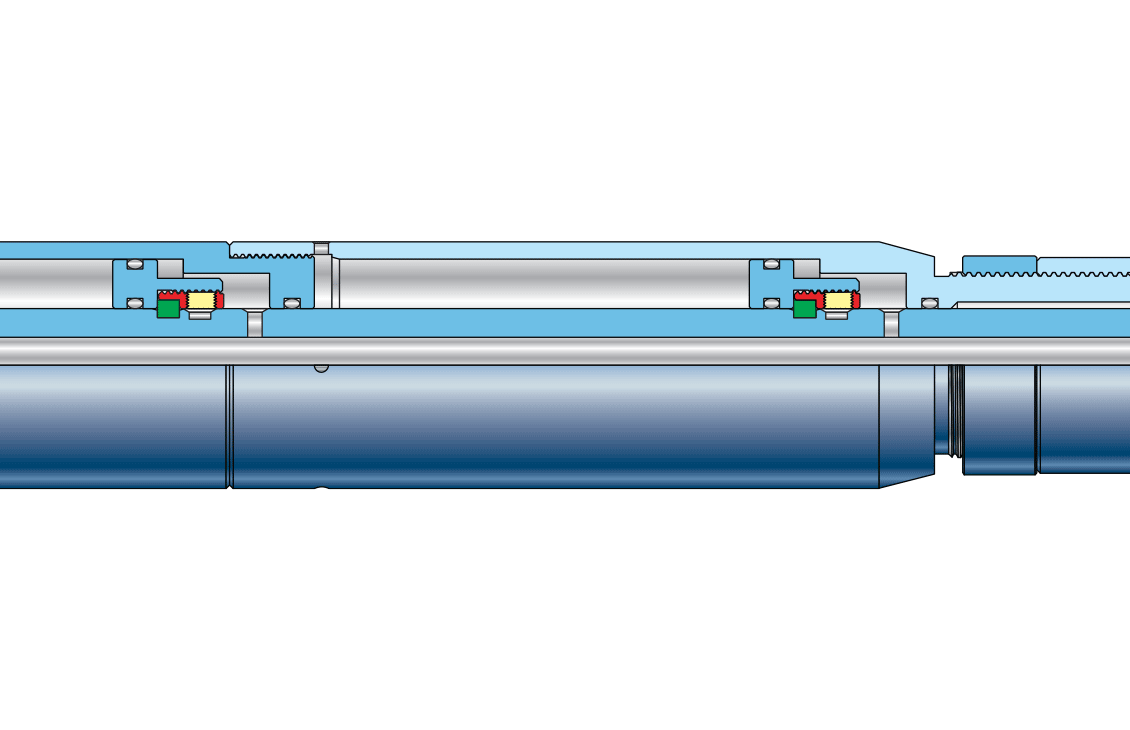

Enable passage of a second completion string, power for an ESP, or additional parallel ports for injection lines, gas vents, and ESP accessories.

Enable passage of multiple feedthroughs for chemical injection, gas vents, or ESP accessories at pressures up to 5,000 psi [34.5 MPa]. View

Install this economical packer for isolation in production or water injection wells to manage up to 5,000-psi pressure differentials. View

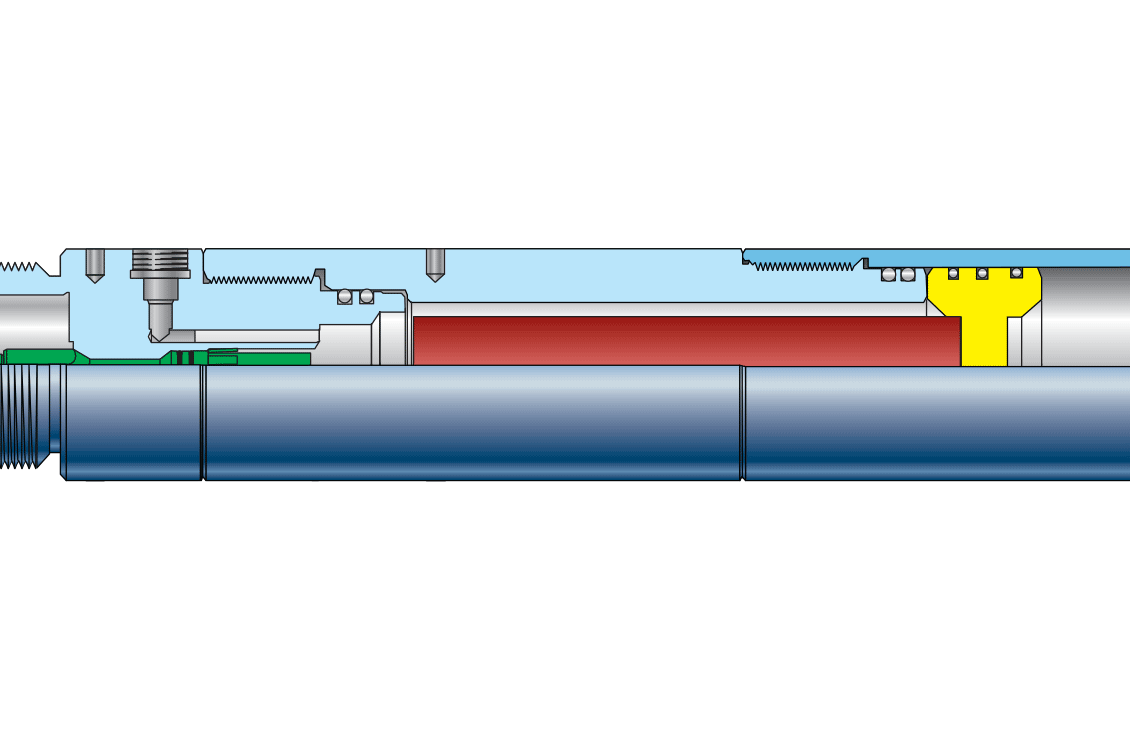

Isolate fluids and pressure in wells with intelligent completions using hydraulic and electric lines for data transmission or control. View

Enable passage of chemical injection or electrical lines, gas vents, or ESP accessories for cost-sensitive applications. View

Isolate single- or multizone intelligent completion with tubing-conveyed, retrievable hydraulic-set production and isolation packers. View

Enable intelligent completions with multiple ports for hydraulic and electric lines. View

Remediate a damaged well or casing, or isolate the openhole annulus with high integrity to ensure zonal isolation.

Set at low pressures to achieve zonal isolation. View

Improve sealing reliability, especially in irregular boreholes. View

Minimize costs and NPT with robust, high-pressure expandable steel annular packers that rapidly isolate zones, even in oval boreholes. View

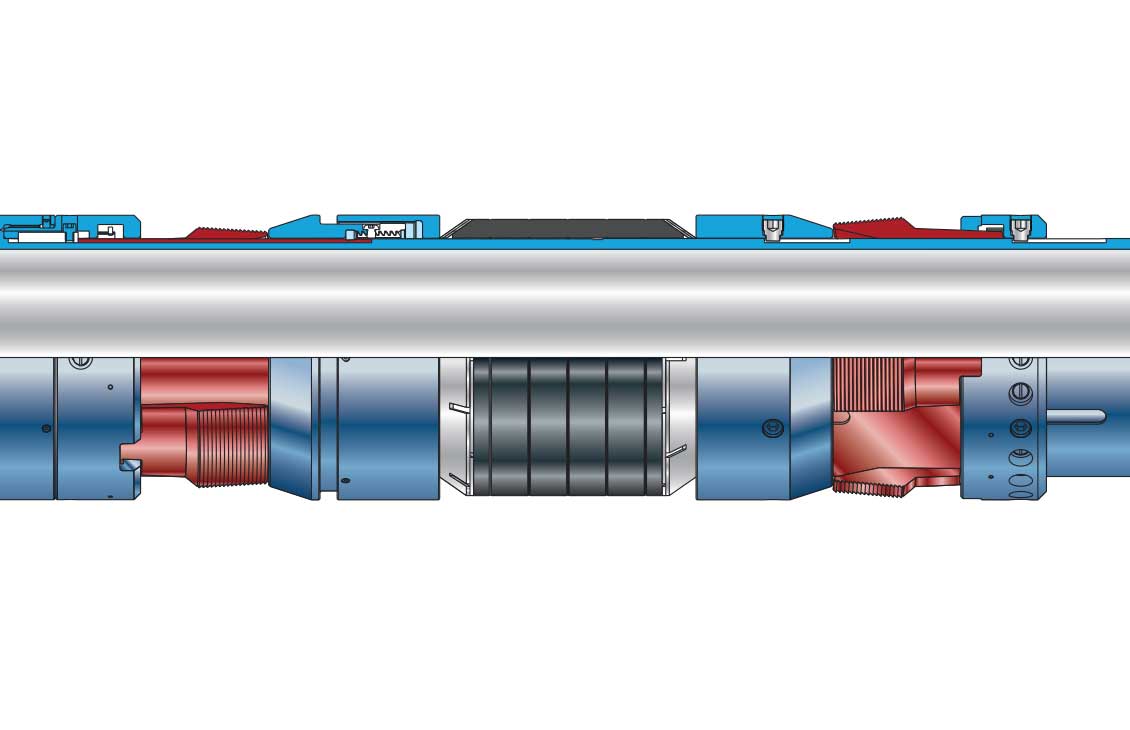

Seal reliably even in high pressures and extreme temperatures with robust technology validated for dependable performance under challenging conditions.

Isolate fluids and pressure in wells with intelligent completions using hydraulic and electric lines for data transmission or control. View

Reduce rig time with a permanent packer with no mandrel displacement, so multiple packers can be set in one string. View

Isolate fluids and pressures in high-rate production or water injection wells, and release with field-configurable options. View

Single-string device that can hold differential pressure from above or below. View

Single-string device that can hold differential pressure from above or below. View

Achieve fast installation with this robust high-pressure production or isolation packer. View

Maximize production and improve performance parameters in HPHT gravel and frac packing, production testing, and drillstem testing. View

Optimize multistage fracturing and ICD or sand screen completions with elements that seal the annulus even in high-pressure conditions. View

Enhance flexibility in single-string production or injection wells from low to ultrahigh temperatures and pressures. View

Save rig time in high-rate deepwater and subsea production and injection wells with single-trip completions up to HPHT conditions. View

Enable intelligent completions with multiple ports for hydraulic and electric lines. View

Ensure zonal isolation for gravel and frac packing applications in conventional and extended-reach wellbores through unconsolidated sands.

Save time on Alternate Path gravel-pack services with instantaneous packer setting, and enable future water and gas shutoff. View

Save rig time by running the QL packer as a production packer, gravel-pack packer, or sump packer in standard or H2S service. View

Achieve fast installation with this robust high-pressure production or isolation packer. View

Save rig time with a single-trip sand control solution for single- and multizone completions. View

Enable efficient performance in high-rate production wells, dual-bore completions, and gravel pack completions. View

Maximize production and improve performance parameters in HPHT gravel and frac packing, production testing, and drillstem testing. View

Simplify onsite feed-through and connection of electric and hydraulic conduits for intelligent completions with gravel packs. View

Streamline running and setting in deviated wells with single-trip gravel-pack completions, and use any QUANTUM packer accessories. View

Facilitate packer installation and inventory for ICD completions, gravel-packing, and acidizing in openhole and cased hole wells. View

Optimize multistage fracturing and ICD or sand screen completions with elements that seal the annulus even in high-pressure conditions. View

Optimize production, injection, or cleanup treatments with mechanically set, retrievable packers.

Run in rapidly on wireline and hold pressure from above and below for treating, remediation, and testing operations in cased hole wells. View

Isolate the annulus for squeeze cementing, stimulation, or testing in wells up to 10,000 psi. View

Manage the most challenging thermal applications with robust, reliable technology designed for wells undergoing extreme temperatures and temperature cycling.

Simplify installation with rotation and improve reliability in thermal applications with nonelastomer elements. View

Maximize isolation and flexibility with liner hangers in conditions that exceed temperature and pressure limits for elastomers. View

Deliver the force required to set packers, plugs, and cement retainers at the ideal depth, even in horizontal and deviated wells.

Reliably sets bridge plugs, cement retainers, and packers on wireline. View

Run and set packers, bridge plugs, and cement retainers on a workstring, production tubing, or coiled tubing. View

Connects frac plugs and production packers to a wireline assembly. View

Create an effective barrier in cased hole wells for well abandonment or remedial cementing.

Create an effective barrier in cased hole wells for well abandonment or remedial cementing above the plug. View

Bidirectional barrier in cased hole wells for well abandonment or remedial cementing below the retainer. View