Product Sheet Production Chemicals Optimization on Delfi

Monitor at 1-minute frequency to optimize ESP corrosion and scale management by autonomous chemical injection.

For flow assurance and asset integrity in oil and gas applications

Our integrated chemistry technologies and services support your asset integrity and flow assurance objectives across your oil and gas operations—upstream, midstream, or downstream—regardless of complexity or geography.

Experienced teams of specialists work with you to identify the root cause of your concerns and develop targeted, value-driven integrated strategies that anticipate, address, and decisively remedy complex production issues. We work with you—using production chemistry, processing and separation technologies, services, and data-driven automation processes—to deliver differentiated technical solutions that enhance your experience and improve your business performance.

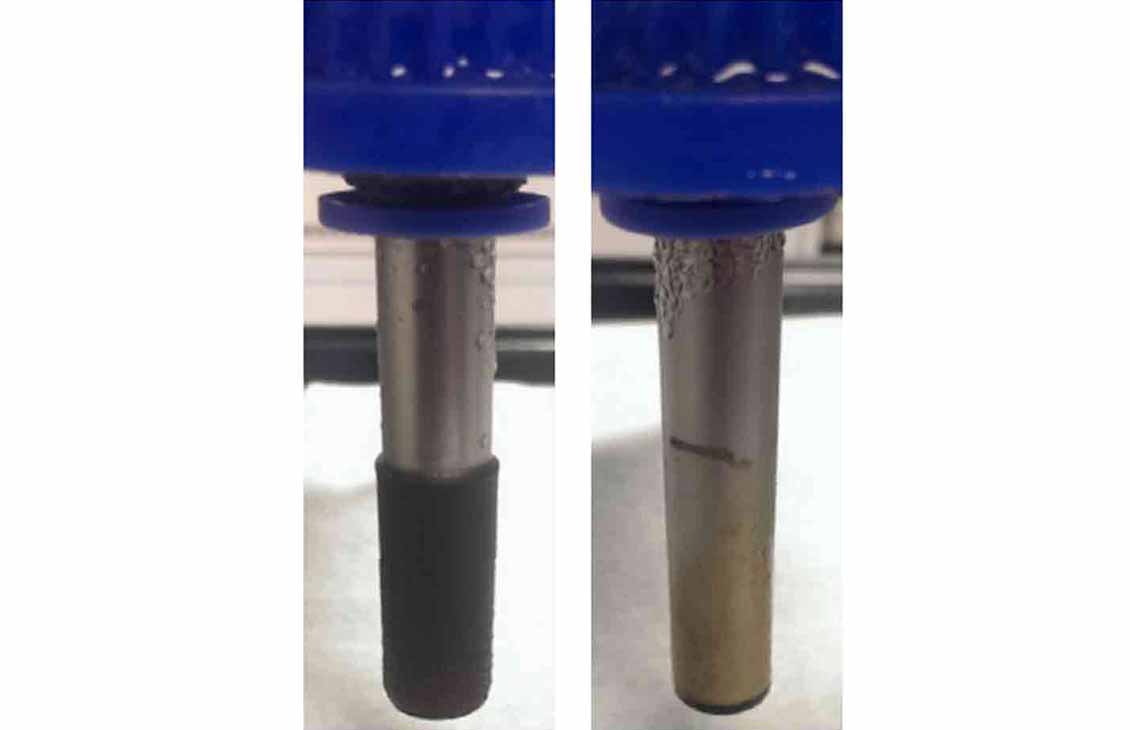

Corrosion is a pervasive aspect of oil and gas production—from wells through to the refinery. It has multiple causes, including CO2, H2S, bacteria, and solids deposition. Preventing corrosion and preserving the integrity of upstream, midstream, and downstream oil and gas facilities is essential to their safe operation, reliable production, and protection of personnel and the environment.

A robust asset integrity program has many individual elements, such as chemical treatments, corrosion monitoring, inspection, and data management and interpretation. You can rely on our proven track record of devising bespoke corrosion control, corrosion monitoring, and data management programs to mitigate risk and support safer oil and gas operations.

Preserve asset integrity with a comprehensive portfolio of chemical treatments. View

We use a four-step integrated approach to detect, mitigate, and prevent microbially induced corrosion. View

Rapidly and cost-effectively evaluate the bacteria control strategy for your field. View

Mitigate corrosion in seawater injection systems, hydrotesting operations, and water treatment equipment. View

Reduce production risk and improve returns. View

Remove harmful H2S from liquid and water-saturated gas streams. View

Mixed-metal-oxides-based adsorbents to remove harmful H2S from liquid and dry and water-saturated gas streams. View

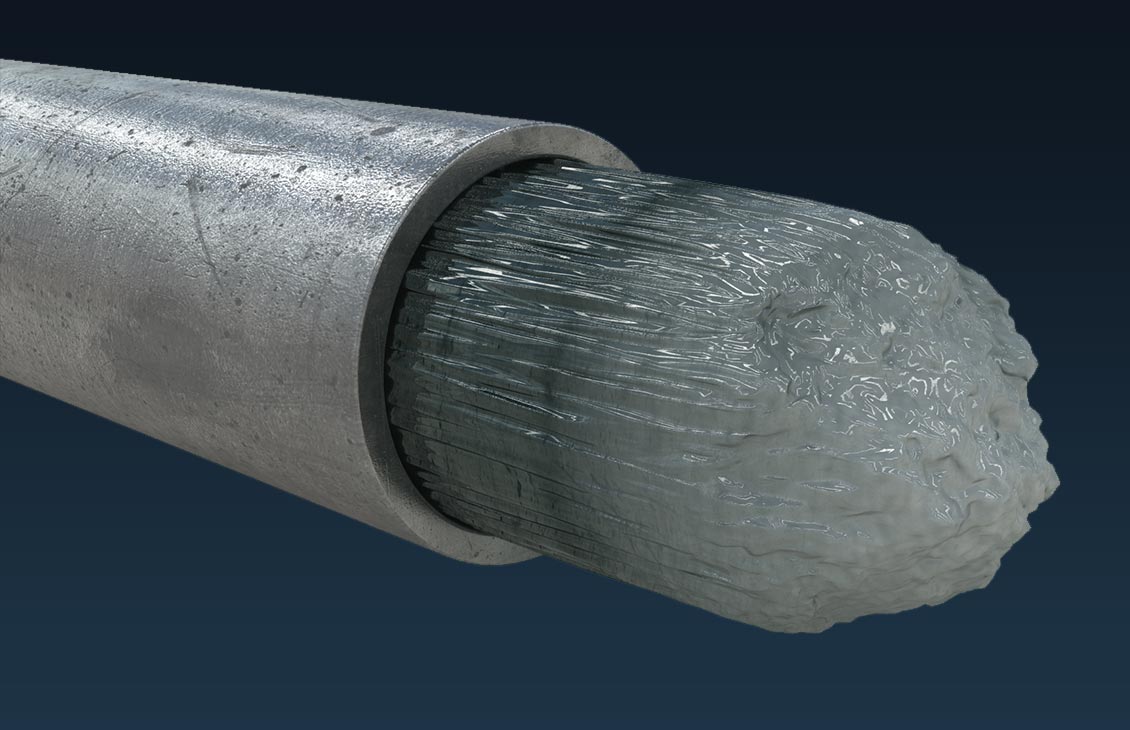

However hostile or difficult the environment, our highly effective and evolving portfolio of products and services can help you maintain optimal production by inhibiting or removing deposits of substances such as scale, paraffin, asphaltene, hydrates, and naphthenates that present flow assurance challenges. We also have a wide range of umbilical-friendly products for deepwater applications.

Remediation of existing flow restrictions can be accomplished with our extensive range of dissolvers and innovative technologies.

Benefit from a comprehensive approach to managing scale and an extensive portfolio of solutions. View

Address the challenge of paraffin deposits, which form when hydrocarbons depressurize and cool. View

Optimal solutions based on field and fluid data, testing, and performance evaluation. View

Cost-effective flow assurance in subsea, deepwater, and unconventional applications. View

Kinetic and antiagglomerant hydrate inhibitors to suit your fluid and field characteristics. View

Stop complex soap formation and remove naphthenate deposits to restore production. View

Maintain optimal operation of your hydrocarbon assets. View

To ensure umbilical-friendly production chemicals for wells in water depths greater than 1,500 ft. View

SLB production chemistry solutions help mitigate the effects of emulsions and foaming, improve operational efficiency, maximize clean oil production, minimize water quality issues (e.g., in produced water for disposal or reinjection and in industrial water), and reduce environmental impact throughout the lifetime of your system.

Optimally dehydrate crude oil and clean aqueous discharge streams. View

Remove oil and insoluble matter from aqueous production streams. View

Unload water and condensate from gas wells. View

Defoamers are highly cost efficient, working at injection rates of just a few parts per million. View

Reduce energy needed for artificial lift, surface boosting, processing, and pipeline distribution of crude oils. View

We supply chemical products to remove contaminants from a variety of gas and liquid streams.

Our industry-leading, cost-effective adsorbents for the selective removal of H2S or mercury are used in fixed-bed processes that are simple and easy to operate and require minimal user attention. During the adsorption process, gas or liquid flows through the adsorbent media, and the contaminant chemically reacts with the media to form a stable by-product. The flexibility of the fixed-bed process enables the system to adapt to variations in process conditions. Product consumption depends only on the amount of contaminant that passes through the bed.

Liquid H2S scavengers can be applied as a solution in bubble towers for gas treatment or via direct liquid injection. A wide range of triazine, aldehyde, and non-nitrogen products are available.

SLB experts can help you select the most appropriate technology and product for your application, based on the process conditions and operational requirements.

Reduce production risk and improve returns. View

Remove harmful H2S from liquid and water-saturated gas streams. View

Mixed-metal-oxides-based adsorbents to remove harmful H2S from liquid and dry and water-saturated gas streams. View

Advanced materials for the treatment of gas and liquid streams. View

Control odor with one universal solution. View

Higher H2S removal capacity compared with activated carbon. View

Our portfolio includes

Our domain experts carry out field surveys, analysis, and laboratory testing to diagnose and recommend the proper combination of specialized chemicals. We pride ourselves on providing a custom approach to each project to ensure cost-effective solutions that are practical and provide value for you.

Maximize your flowline efficiency with customized chemical cleaning services, technologies, and workflows. View

Understand flow to optimize your applications. View

We provide a suite of digital products, tiered to meet any operational requirement and expectation. From data integration and distribution to fully remote or autonomous chemical injection, your chemical program status is always current, contextual, and available on demand. This is achieved through innovative edge intelligence, cloud-based visualization, and autonomous data-driven actions.

Our standardized digitalization approach is applicable to single-well operations, large facilities, and across multifield and global enterprises. Its foundation is data, your single most valuable asset. Acquisition and preservation of source data, identification of information gaps, and real-time collaboration are the fundamentals of this approach. SLB production chemistry digital solutions provide unparalleled perspective, enable timely response, and pave the way to chemical program optimization.

Removes administrative tasks from your team with chemical data management software. View

Monitor at 1-minute frequency to optimize ESP corrosion protection and run-life extension. View

Throughout product and service delivery, our Chemical Management Service (CMS) Standard confirms and ensures supply of the resources and activities required to identify, develop, and secure production technology enhancements that will deliver value to your operations while achieving excellence in QHSE performance.

Successful deployment of our customized chemical solutions and management services is supported with the ChemWatcher integrated chemical management system, enabling you to maximize production, mitigate NPT, and minimize total operational cost.