Tech Paper Realising Lost Well Productivity via Wellbore Implosion

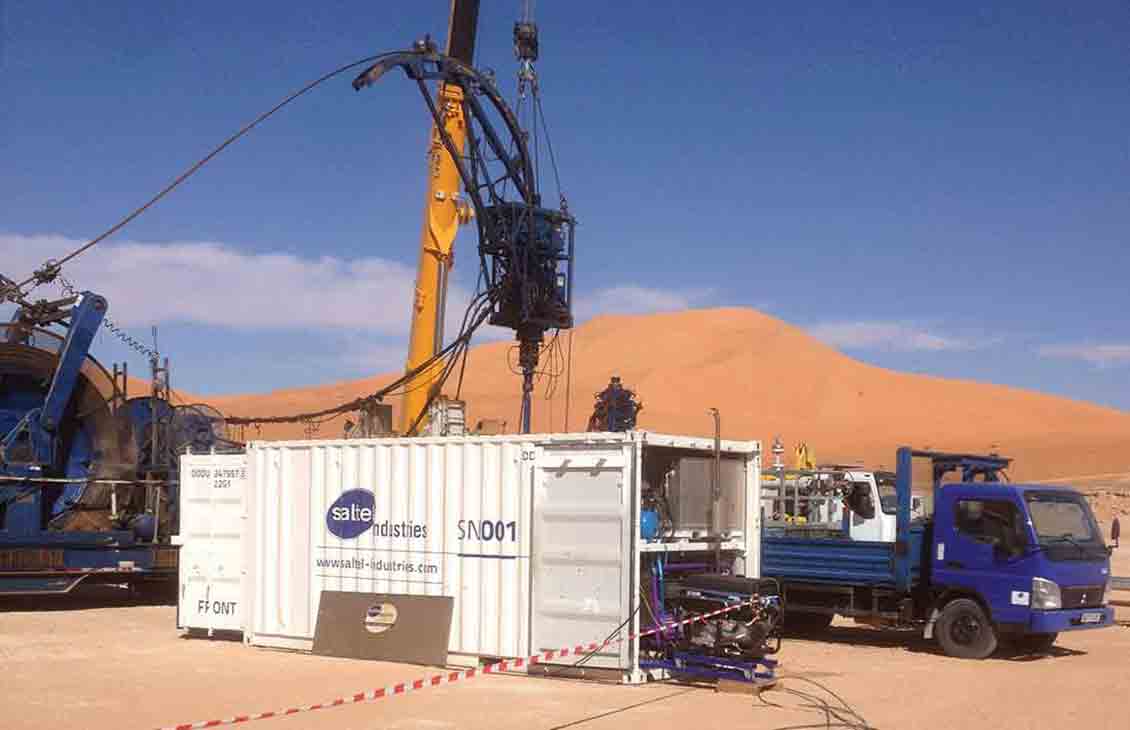

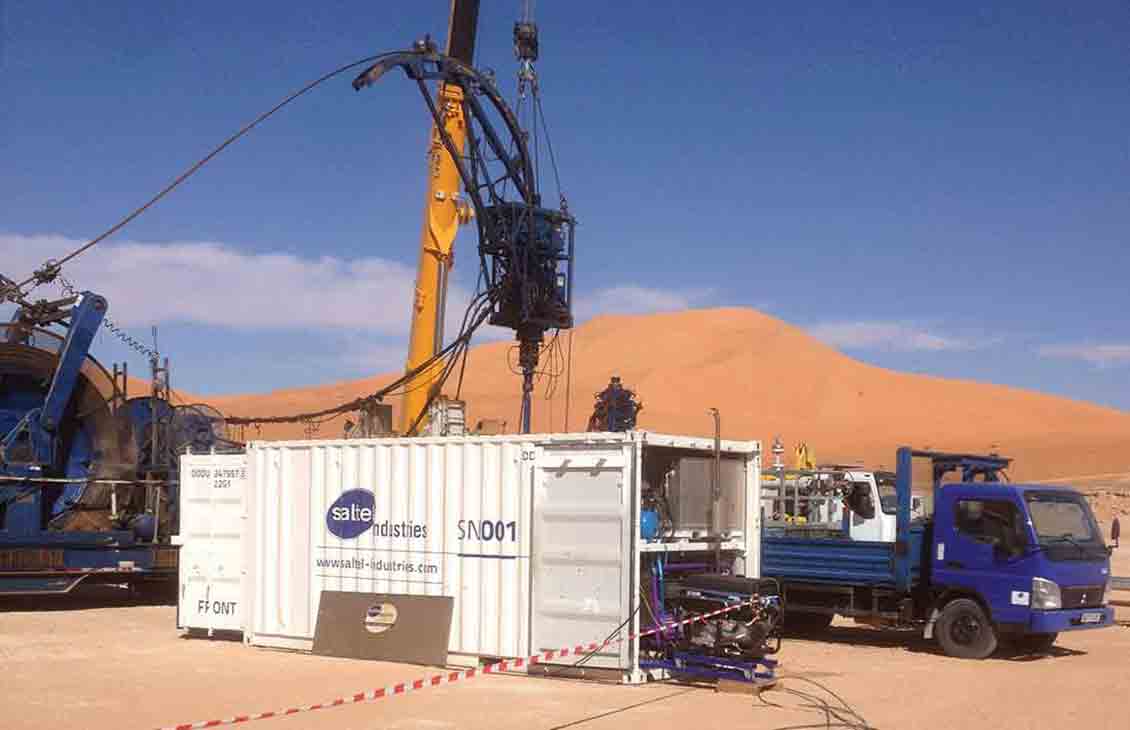

Successful application of WIC wellbore implosion technique in cleaning existing perforations.

Restore production and completion integrity in unconsolidated formations

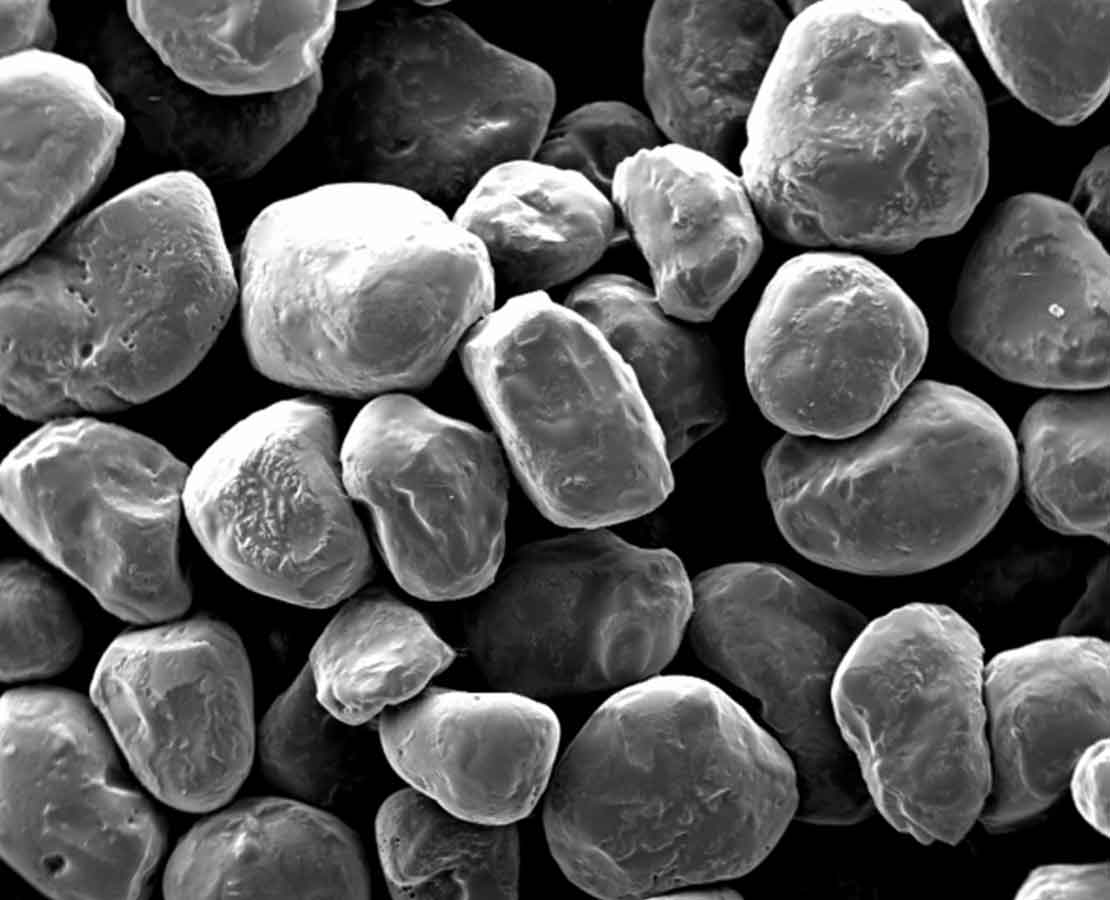

Sand management efforts are most effective when engineered and deployed early in the life of the well, but early water breakthrough or high drawdown in a mature well can lead to unexpected sand and fines that hinder production and damage lifting equipment. In addition, even the most robust, well-engineered sand control technologies require remediation after many years of corrosion, erosion, or plugging damage.

From conventional straddle packers that shut off a damaged screen to state-of-the-art chemical systems that stabilize sands with little permeability impairment, we have a full range of technologies to help you restore production and completion integrity and prevent further damage.

Restore production after sand, fines, scale, and other solids plug the completion or wellbore.

Perform wellbore cleanouts including sand lift, tubing-scale removal, sand screen cleaning, and near-wellborn skin removal. View

Isolate zones in chemically harsh and high-temperature environments. View

Improve intervention effectiveness with real-time downhole measurements. View

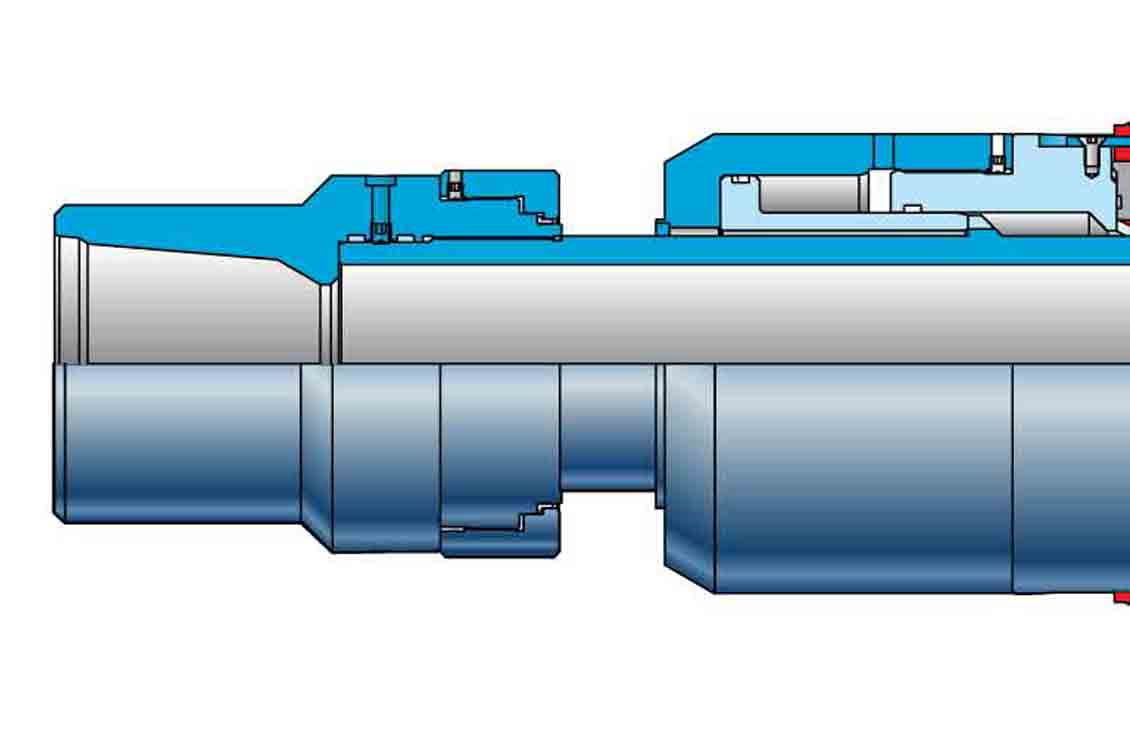

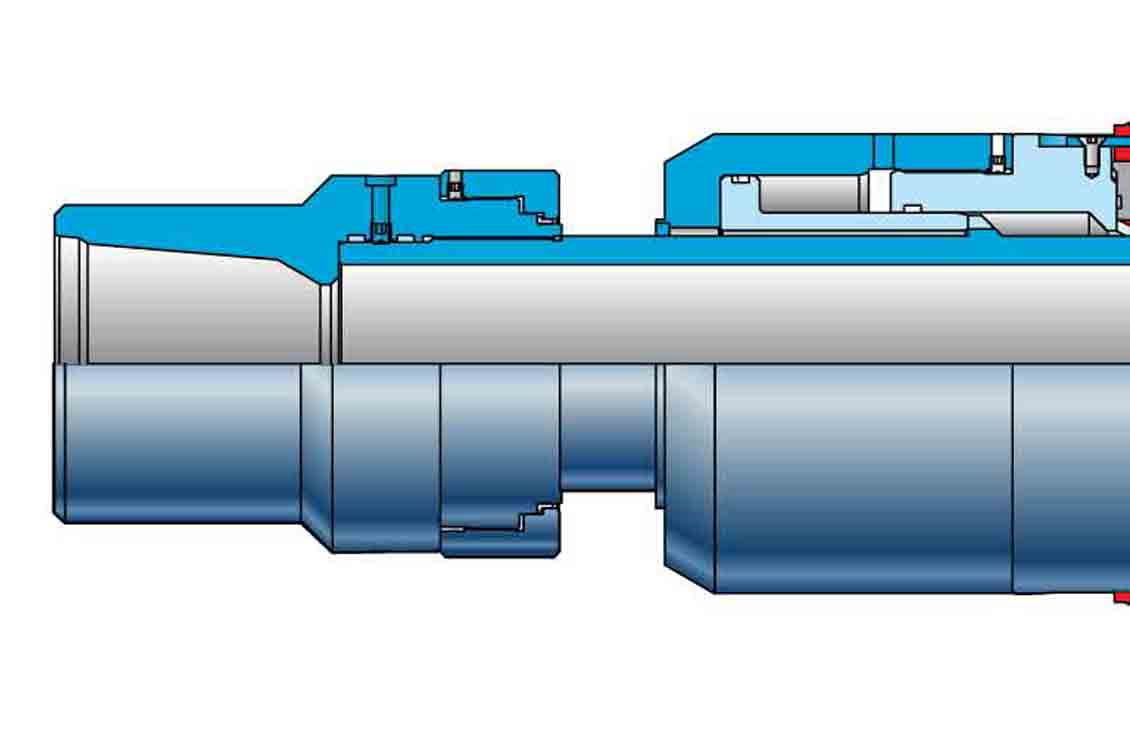

Remediate or replace eroded, corroded, and damaged sand screens—without pulling the whole completion.

For casing leak repair, perforation shutoff, tubing repair, and geothermal well integrity restoration. View

Isolate the annulus for squeeze cementing, stimulation, or testing in wells up to 10,000 psi. View

Prevent screen and completion damage. View

Shut off perforations or zones after water or gas breakthrough to restore deeper hydrocarbon production.

Isolate the annulus for squeeze cementing, stimulation, or testing in wells up to 10,000 psi. View

Improve hydrocarbon recovery and sweep efficiency by balancing flow across intervals with permeability variations. View

For casing leak repair, perforation shutoff, tubing repair, and geothermal well integrity restoration. View

Manage or shut off water and gas production with application-specific permeability modifiers, chemical blocks, or cements. View