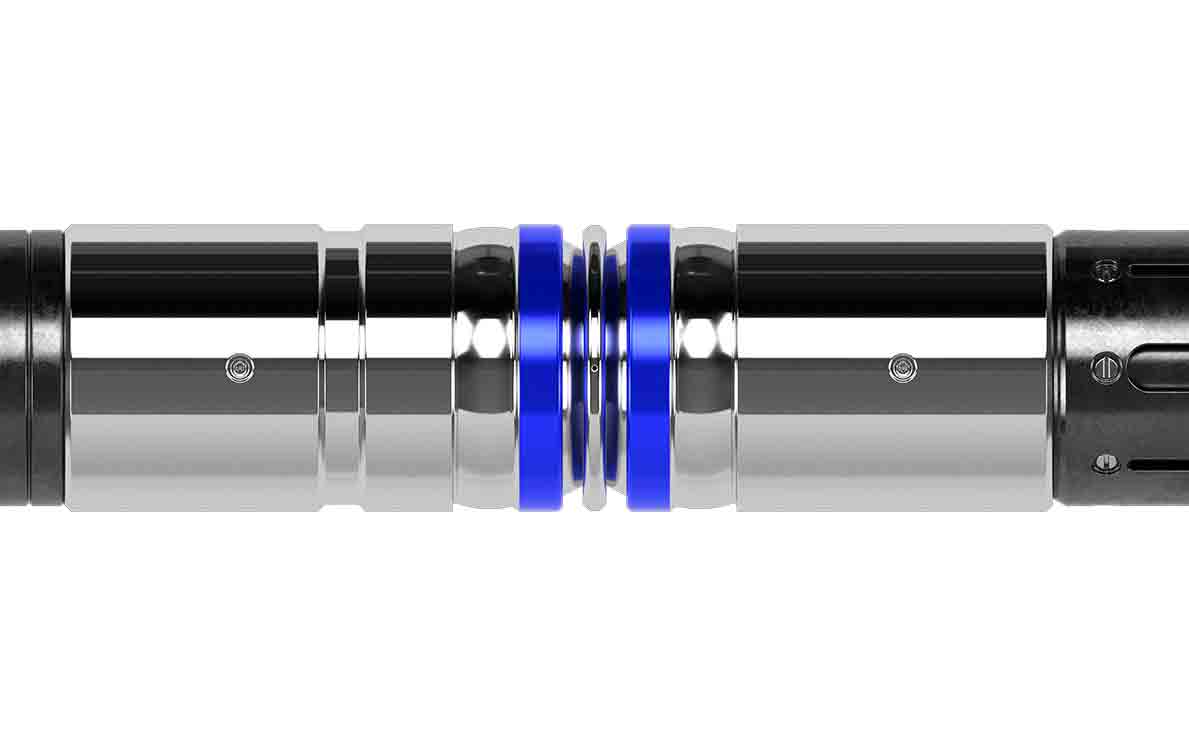

Case Study Wireline E-Cutter Salvages Rigless Pumpdown Operation

Nonexplosive Peak eCutter wireline cutter saves fishing job and enables fracturing to resume in 24 h.

Simply reliable flow control and mechanical well intervention

The simplicity and reliability of deploying advanced downhole tools designed and manufactured by Peak Well Systems bring numerous benefits. You can more easily sustain production, restore integrity, and enhance well performance with tools that are purely mechanically set on slickline or other conventional forms of conveyance.

This SPE paper outlines the features of the unique nonexplosive cutter and includes several case studies from onshore and offshore operations.

Read Tech Paper

By embedding safety and excellence in every aspect of our processes and activities, Peak Well Systems proactively identifies and mitigates risks to product quality and performance. We do the upfront work to make sure your slickline operations are simpler and safer to deliver reliable results.

Sealing integrity solutions

Key to reliable flow control is the sealing elements incorporated in the downhole equipment used to isolate one zone from another. This means that the fluid type and well temperature and pressure must all be considered—in addition to the well completion, regulatory requirements, and retrievability—when selecting the appropriate tools and equipment to deploy on slickline.

To meet these needs, we provide simple and reliable mechanically set plugs from the SIM sealing integrity management system.

SIM system plugs are a vast array of slickline-conveyed and recoverable devices for effective flow control. These plugs and the tools for installing them are extensively qualified to different grades and can be set to provide a well barrier anywhere in the tubing, without the need for a nipple profile.

Reliably set, seal, and retract on slickline and seal with a hybrid metal-elastomer element. View

Fully certified grade V3 plugs provide a debris-tolerant retrievable barrier with no nipple profile needed. View

Install anywhere in your well, no nipple required, to hang gauges or provide a platform or suspension. View

Reliable, nippleless flow control for reduced operating costs, improved safety, and better well performance. View

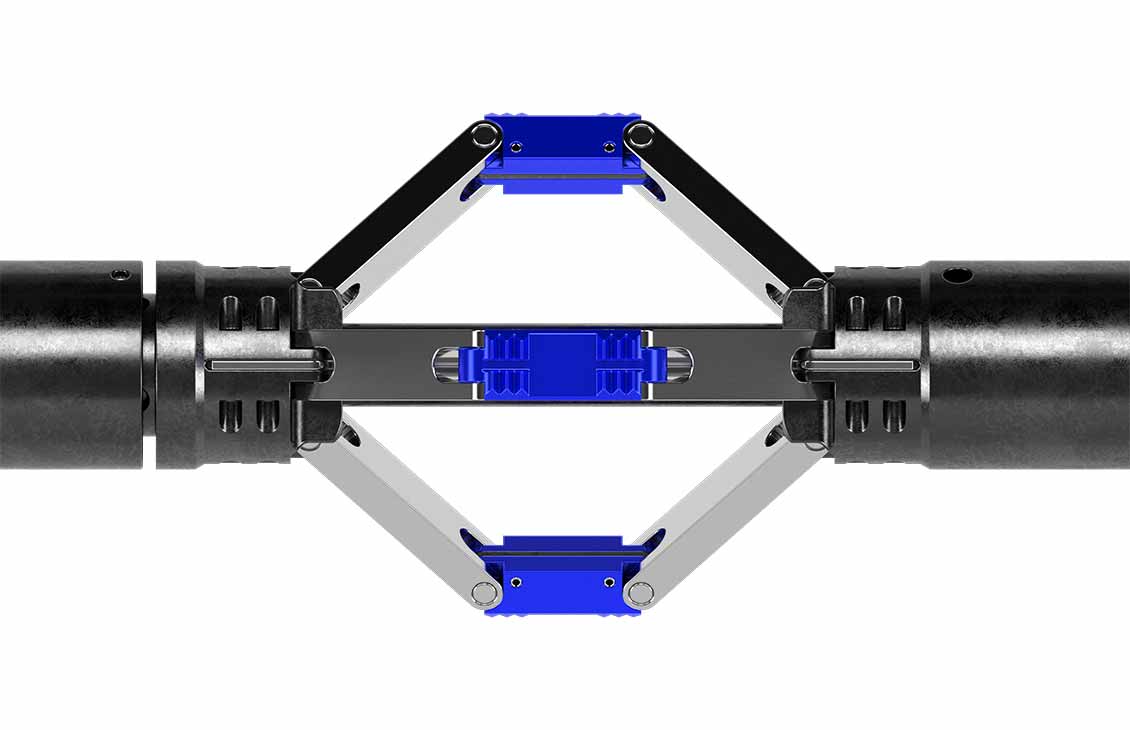

Advanced mechanically operated tools for wellbore intervention

When well intervention is needed to remove debris or cut the wire to a stuck toolstring, slickline operations can be the most economical solution for quickly resolving the situation. Slickline’s smaller footprint facilitates mobilization to save precious time.

By deploying mechanically operated tools, you’ll benefit from their high functionality and flexibility in getting the job done:

Battery-powered electronic activation reliably severs slickline or cable when a toolstring sticks downhole. View

Battery-powered electronic activation reliably severs heavy-duty cable to stuck tools in high temperatures. View

Jarring down mechanically efficiently removes sand and scale concretions. View

Leverage interchangeable rollers that assist wireline toolstring conveyance in high-angle wells. View

Innovative downhole technologies for well intervention