3D Far-Field Sonic Service

Automated subsurface feature extraction

Expedite processing and interpretation up to 10× faster than conventional methods.

Through-the-bit logging services

ThruBit™ through-the-bit logging services offer a comprehensive wireline suite built for performance in complex and unstable well environments. This unique conveyance platform provides a set of slim-profile (2 1/8-in) formation evaluation tools designed for advanced lateral measurements in all types of difficult-to-access wells.

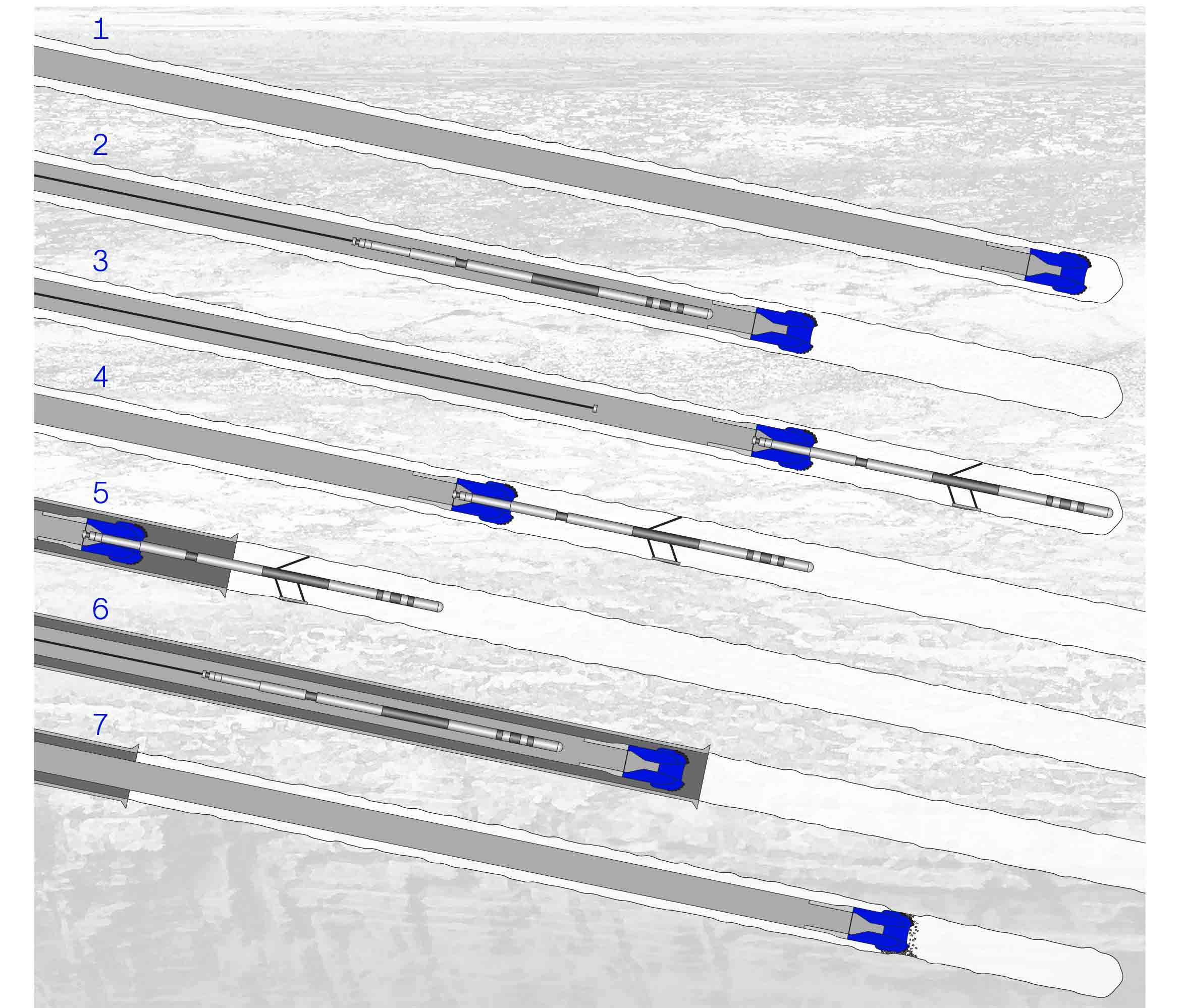

No longer are operators limited to time-consuming specialty conveyance equipment—or skipping logging altogether. A logging string with any number of ThruBit services measurement tools can be conveyed through the drillstring and the Portal™ pass-through bit to log the open borehole on wireline or as the drillpipe is tripped out of the hole. With ThruBit services, you get a much more complete lateral understanding of drilling challenges, to help eliminate uncertainties during fracturing and stimulation operations and fully optimize your stimulation plan.

Petrophysics

Geology

Acoustics and geomechanics

Geophysics

Drillers maintain complete drillstring control with easy tool retrievability—even in stuck-pipe situations—to facilitate and derisk fishing and pipe-freeing operations.

A wide range of advanced through-the-bit logging tools provide advanced lateral measurements to help eliminate assumptions during fracturing and stimulation.

Lateral measurements help improve your understanding of subsurface conditions to get the greatest potential production from your assets.

The ultraslim platform works well in slim holes and extremely rugose, deviated, or horizontal wells to provide the most accurate available inputs to your stimulation plan.

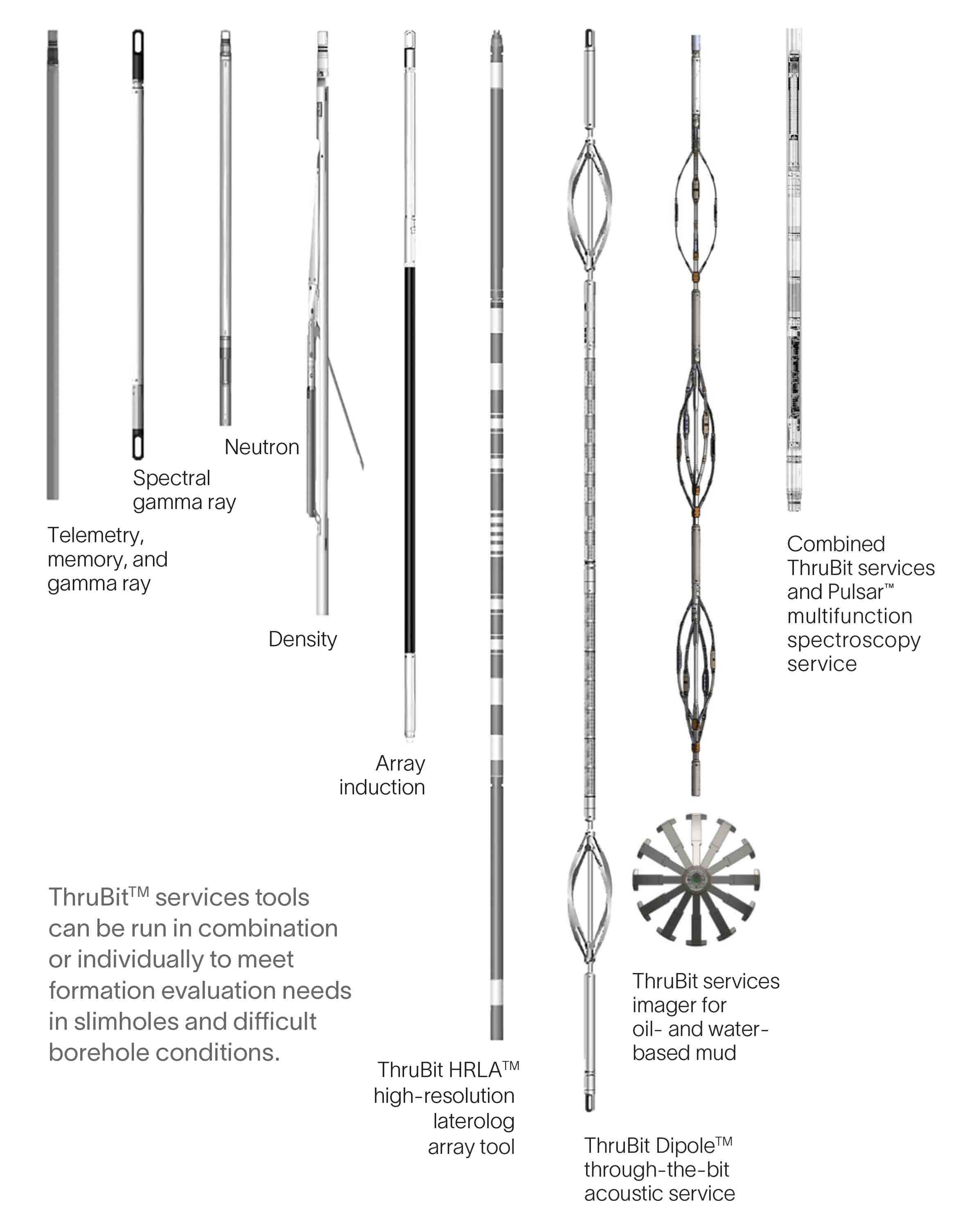

ThruBit services formation evaluation tools provide a complete suite of logging measurements for better insights in the most challenging environments. Packaged to fit a slim 2 1/8-in profile, these rugged, through-the-bit tools can deliver measurements ranging from the classic triple-combo suites to advanced offerings such as high-resolution laterolog, spectral gamma ray, dipole sonic, borehole imaging, and multifunction spectroscopy.

| ThruBit Services | Description |

| ThruBit services triple-combo | Neutron, density, and array induction resistivity combined with the telemetry, memory, and gamma ray device available with all ThruBit services tools gives you extensive data for your stimulation plan. |

| ThruBit HRLA™ high-resolution laterolog array tool | Measurement by focused arrays at multiple depths enables determining and correcting for environment effects, such as shoulder beds, and calculating uninvaded formation resistivity. |

| ThruBit services spectral gamma ray tool | Measurement of the total gamma ray spectra enables detection of potassium, thorium, and uranium, which are common in sands and shales. |

| ThruBit Dipole™ through-the-bit acoustic service | Both monopole and cross-dipole waveforms and Stoneley waves help determine whether the formation is isotropic or anisotropic—critical information for designing well paths, completions, and fracturing stages. |

| ThruBit services imagers | Designed for use with OBM or WBM, imaging and dip data covers 80% of the borehole in 6-in holes with .2-in image resolution for high-resolution structural, stratigraphic, and geomechanical understanding. |

| ThruBit services multifunction spectroscopy | Multiple detectors paired with a high-output pulsed neutron generator provide cased-hole formation evaluation and reservoir saturation monitoring data—all in a single tool. |

Eliminate additional trips and save rig time by deploying the toolstring and logging during hole conditioning.