Case Study Radioactive Toolstring Retrieved After BHA Mishap

Flexible ReSOLVE iX Service Retrieved Nuclear Source Without Heavy Equipment or HSE Incidents

Reinvent your interventions

Winner of the OTC 2022 Spotlight on New Technology Award for ReSOLVE iX extreme-performance instrumented wireline intervention service

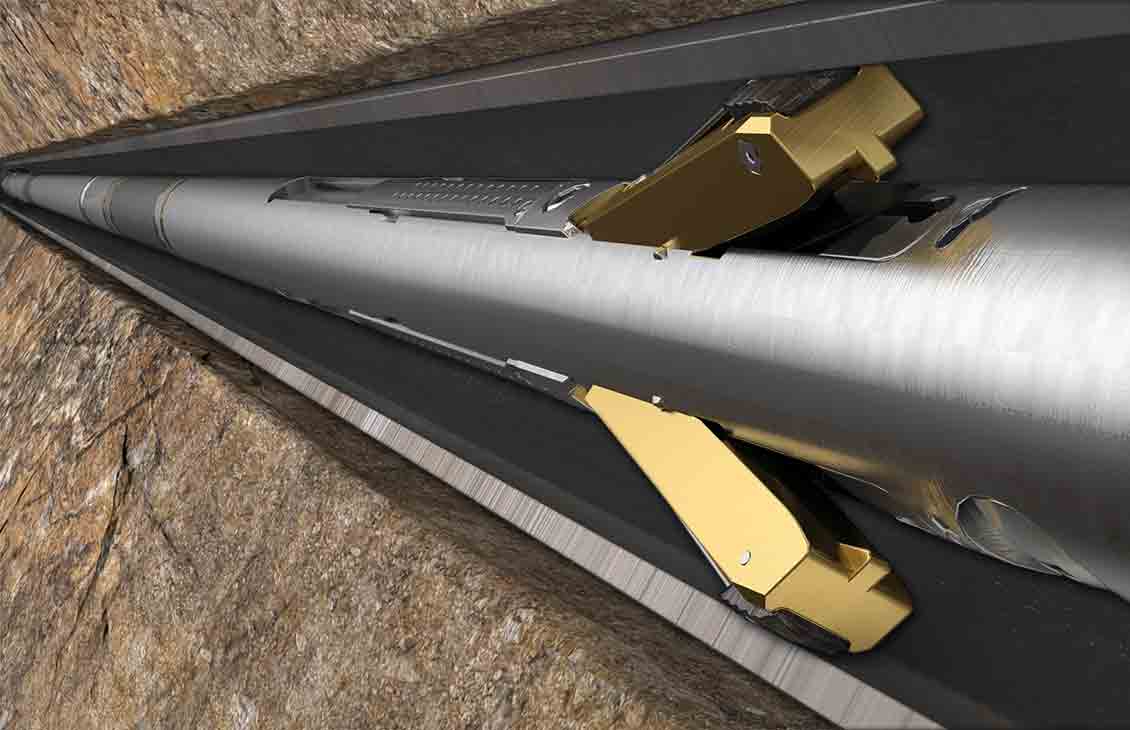

The wireline powered intervention services family expands the operating envelope and ensures a more successful outcome in well intervention—seamlessly integrating ReSOLVE Family instrumented wireline intervention services with StreamLINE iX extreme-performance polymer-locked wireline cable, TuffTRAC cased hole services tractor, and TuffTRAC iX extreme-performance wireline tractor.

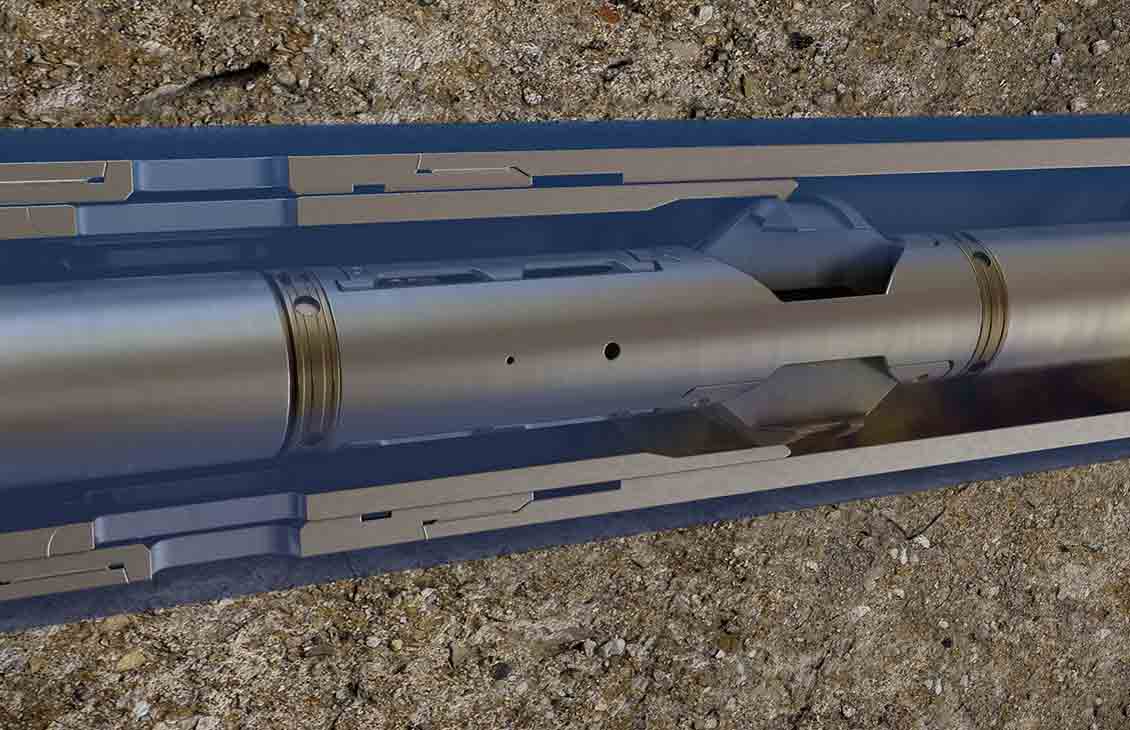

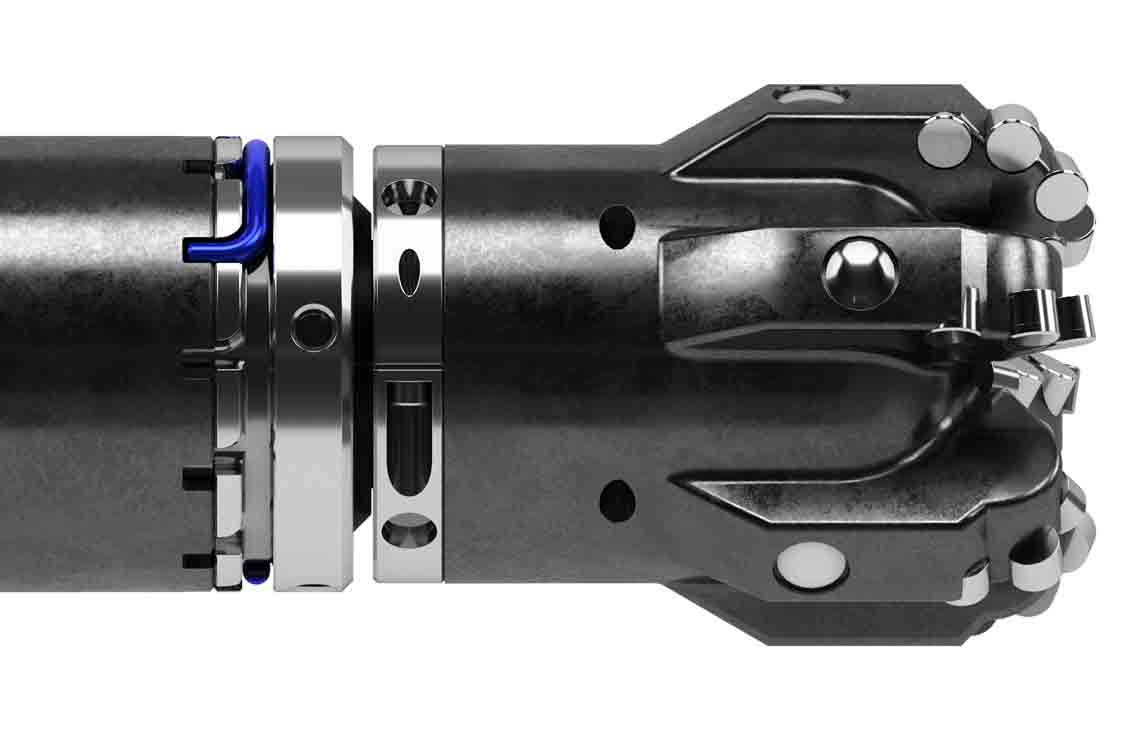

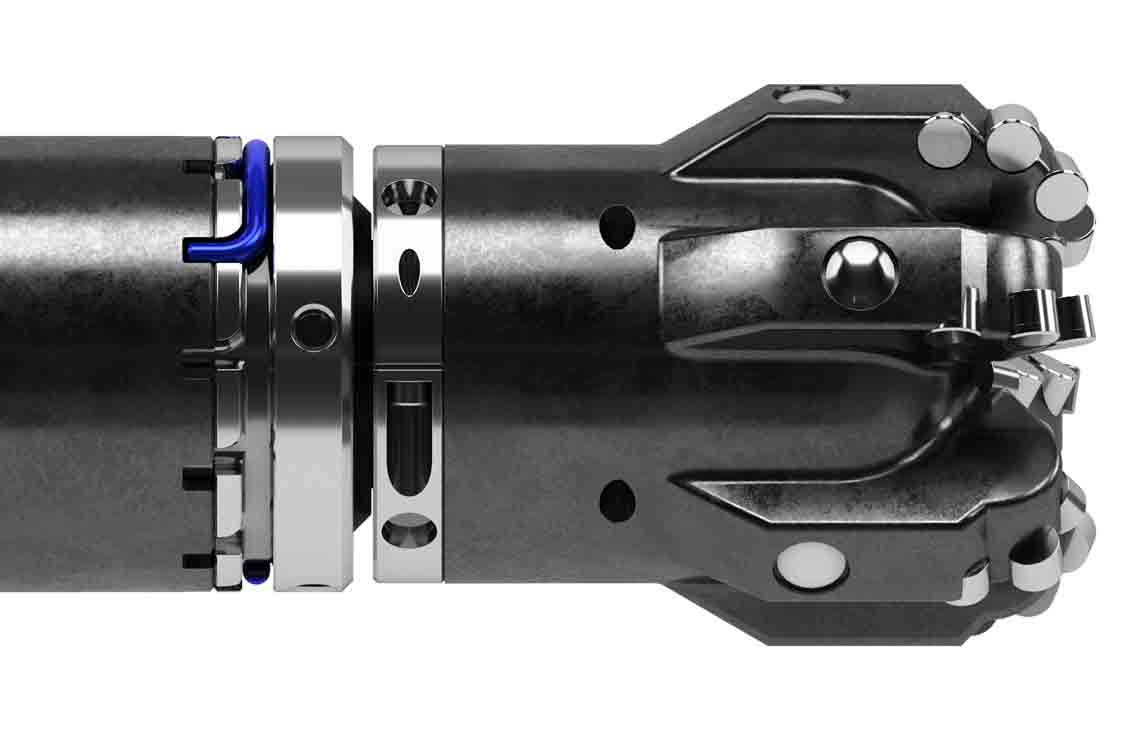

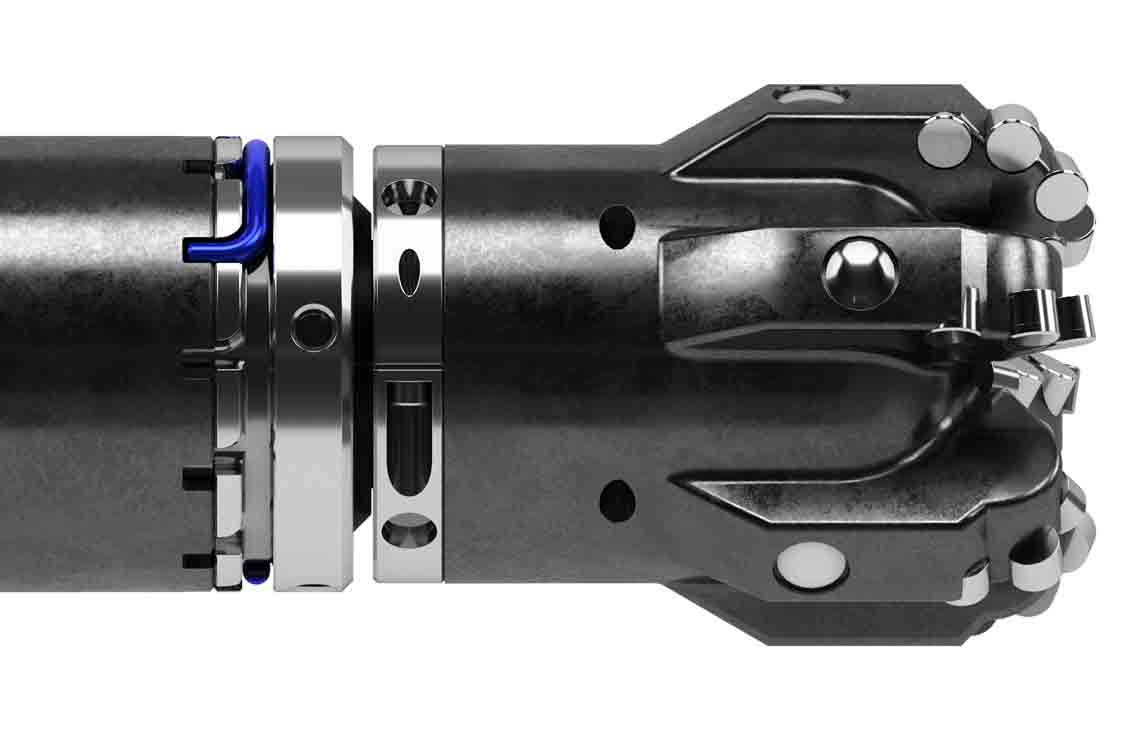

Now available in two sizes, ReSOLVE Family services comprise the 3 1/8-in ReSOLVE instrumented wireline intervention service and 2 1/8-in ReSOLVE iX extreme-performance instrumented wireline intervention service and can be adapted to meet your objectives and maximize intervention impact. ReSOLVE iX service capabilities are uncompromised by its size and enable intervention in extreme conditions, such as complex completions with small restrictions and sour and HPHT environments.

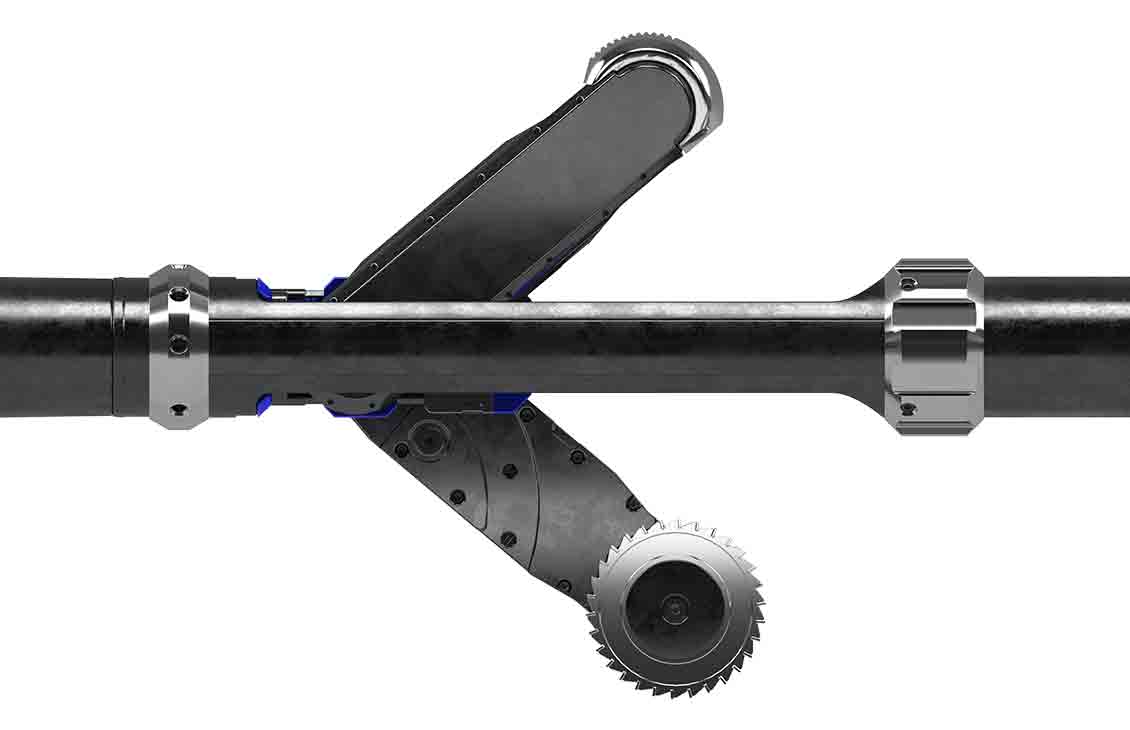

From completion accessory milling, wellbore fill or deposits removal, shifting, and fishing to plug setting and more, applications are unlimited and made possible by a wide range of cutting-edge hardware, powered by instrumentation, downhole automation, and digital capabilities. Our advanced application engineering (AAE) team can customize solutions to resolve your challenges. The ReSOLVE iX service award-winning slot cutter is the latest addition, developed by our AAE team within 9 months from concept to job execution.

The instrumentation enables more than 200 real-time downhole measurement and diagnostics, visualized in a user-friendly dashboard. You can now confirm operations as they happen and quickly adjust your actions to address downhole uncertainties without pulling out of hole.

Furthermore, ReSOLVE Family services are engineered with downhole automation to react faster and deliver the best results. There are more than 40 downhole automation sequences, from stroking, opening anchors, managing motor and voltage, milling, and many more.

Learn from our best practices and success stories and find out how we can customize our services and technologies to meet your objectives.

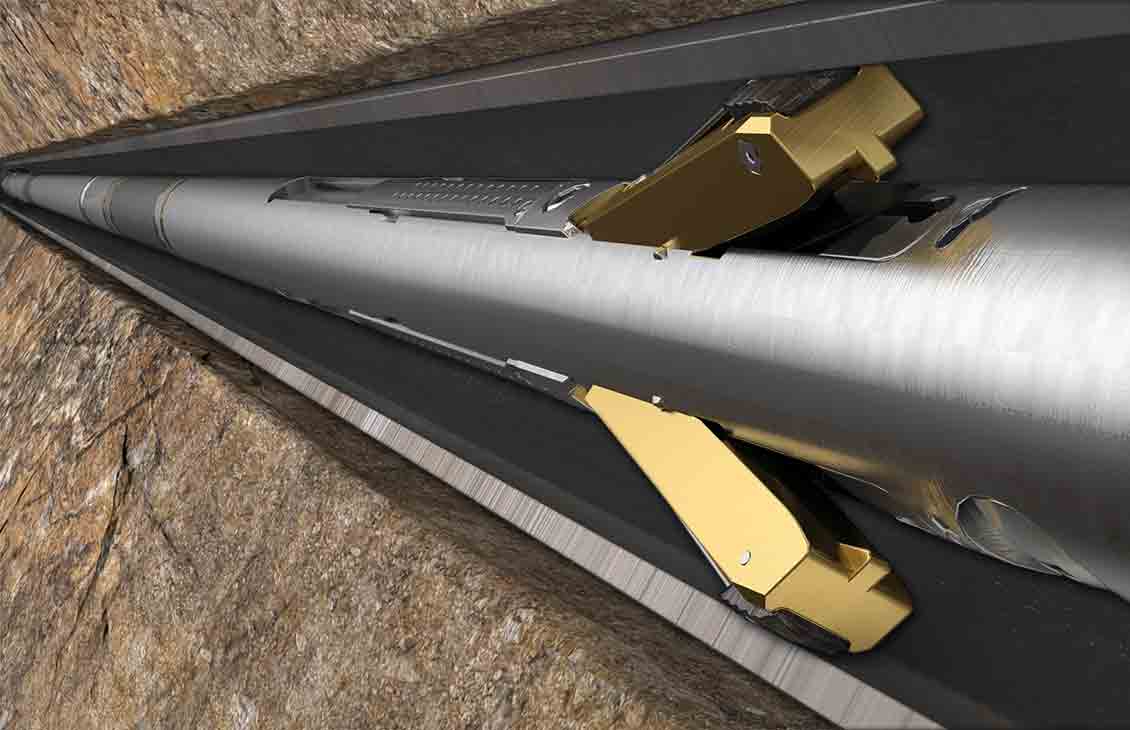

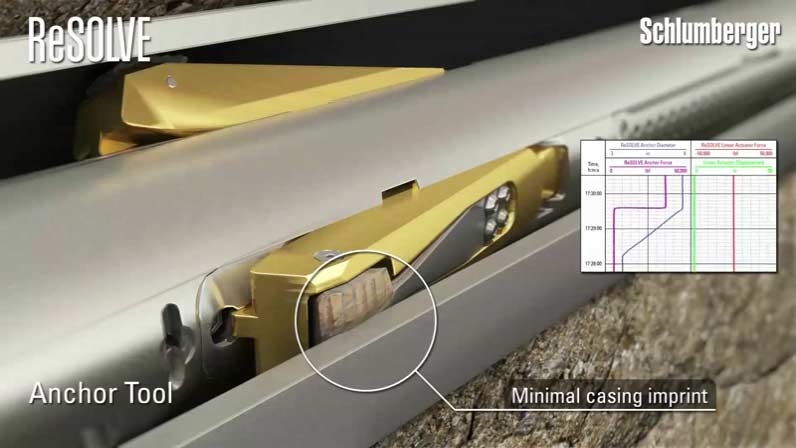

Employ controlled, high-force linear actuation with high-expansion anchoring capability. View

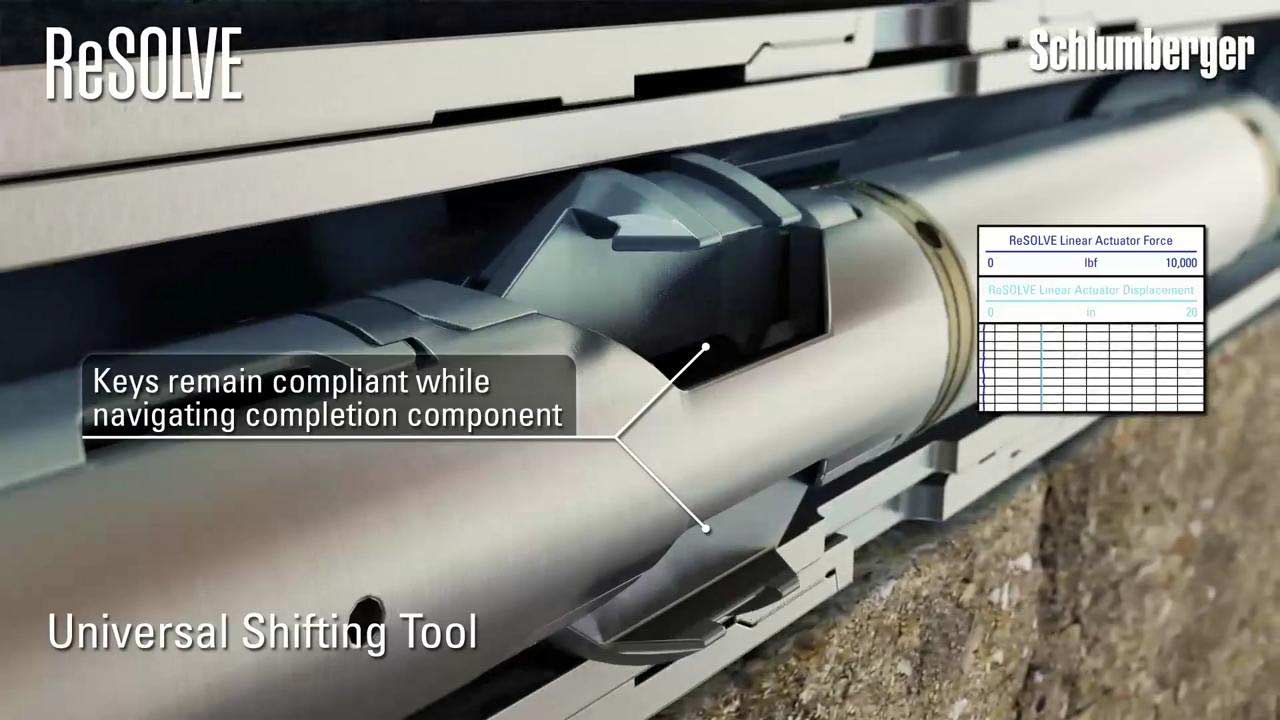

Perform multiple measured shifts in any direction to single or multiple components. View

Innovative linkage designs enable passage through 2.2-in-diameter restrictions and deployment in casings up to 5-in ID. View

Monitored debris collection and confirmed valve shifting to replace time-consuming coiled tubing operations with just two wireline runs, Gulf of Mexico. View

Precise control and real-time confirmation of selective openings in multizone horizontal well, the Middle East. View

ReSOLVE iX service tools diagnose two previously inaccessible sliding sleeves in ultradeepwater well, GOM. View

Demonstrates the unique capability and the flexibility of the service possibilities with the shifting tool. View

Reliably apply controlled axial force to well components. View

Makes multiple shifts in any direction in a single run to one or multiple components in multizone completions. View

Precise machining of completion elements with real-time measurement of milling progress. View

Tractors deploy and power wireline milling tool from light well intervention vessel. View

Design features that made a step change in the efficiency and usability of milling services. View

Maximizes milling efficiency and prevents stalling using seamless integration with the TuffTRAC tractor. View

Maximizes milling efficiency and prevents stalling using seamless integration with the TuffTRAC tractor. View

Commence and optimize debris collection using real-time measurements. View

Design features that made a step change in the efficiency and usability of milling services. View

MillOptimizer autonomous milling system seamlessly integrates milling tool and UltraTRAC tractor for optimized WOB, offshore Norway. View

Rigless intervention with ReSOLVE iX service clears debris fill that couldn’t be bailed to access disc. View

New tool efficiently collects fine solids and viscous slurries of solids and pipe dope. View

Monitored debris collection and confirmed valve shifting to replace time-consuming coiled tubing operations with just two wireline runs, Gulf of Mexico. View

Employ controlled, high-force linear actuation with high-expansion anchoring capability. View

Maximizes milling efficiency and prevents stalling using seamless integration with the TuffTRAC tractor. View

Where a conventional tractor failed in Bakken well, linear actuator strokes 68 times to release and move plug past restrictions, Williston basin. View

Real-time monitoring of downhole forces characterizes the downhole pressure differential, North Sea. View

Reliably and securely set plugs and packers without explosives. View

Hydraulically powered, providing a large force of up to 78,000 lbf for setting plugs and packers. View

Tubing gap and restrictions successfully negotiated for the nonexplosive setting tool to install plug with real-time confirmation. View

Real-time monitoring of downhole forces characterizes the downhole pressure differential, North Sea. View

Real-time downhole measurements confirm set quality on conventional wireline in Tahiti field for Chevron. View

Precise, versatile cutting for various downhole well intervention applications View

Watch how the ReSOLVE iX service slot cutter enables up to 200 cuts per wireline run. View

Precise, reliable, safer mechanical tubing cutting View

ReSOLVE Family services comprise the ReSOLVE instrumented wireline intervention service for regular 3 1/8-in OD applications and ReSOLVE iX extreme-performance instrumented wireline intervention service for more complex, 2 1/8-in OD applications.

Maximize milling efficiency using the MillOptimizer autonomous milling system for seamless orchestration with the TuffTRAC tractor or TuffTRAC iX extreme-performance tractor.

Commence and optimize debris collection using real-time measurements.

Enable efficient and effective pushing and pulling with 1-mm displacement measurement resolution.

Perform multiple measured shifts in any direction to single or multiple components in one run.

Reliably and securely set plugs and packers without explosives.

Deliver up to 200 cuts per run and at up to 60% faster than other mechanical methods.

Machine completion elements with precise, real-time measurement of milling progress.