Video Process Live Service: GHG Control

Process Live service greenhouse gas management delivers data to help you proactively mitigate leaks while reducing costs from product loss or regulatory impacts.

Data-enriched performance service

Optimize the economic performance of your production network and process facility―from point source to enterprise level. Process Live data-enriched performance service leverages the support of OEM domain experts with a full system view that can reduce your costs while improving your profits.

Process operations rely on complex hardware and software systems to ensure optimal hydrocarbon processing and reservoir pressure support. Equipment failures, often stemming from inlet stream changes or degradation, lead to production deferment and unscheduled maintenance that detrimentally affect operation economics.

Traditionally, the industry has managed process equipment performance with scheduled maintenance that may not reflect rapidly changing source hydrocarbons or operational conditions. There is a step change in the industry tied to economics and environmental impact drivers. Operators increasingly need more in-depth equipment and process optimization using OEM knowledge and expertise.

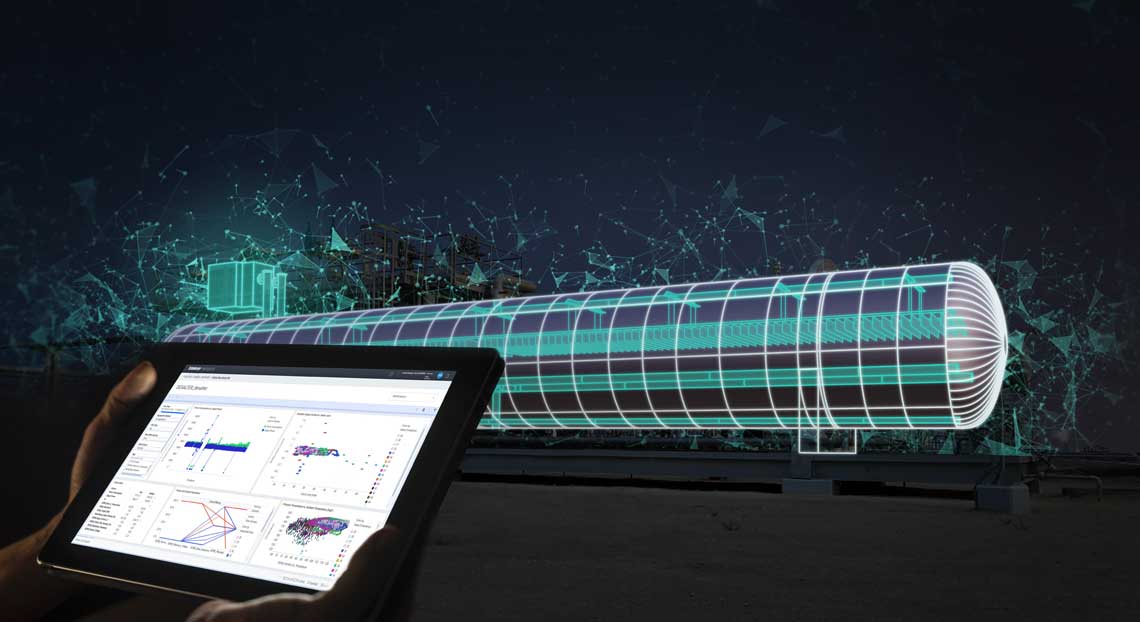

Process Live data-enriched performance service is a multifaceted offering for uptime assurance, process optimization, and greenhouse gas (GHG) control. It integrates digitally enabled equipment, collaboration with OEM experts, and maintenance to enhance asset life cycle management.

The first level of service focuses on equipment uptime assurance with data-driven condition-based monitoring and prognostic health management algorithms that give you actionable insights to help you optimize process equipment performance. We also embed automation algorithms to optimize the performance of your equipment. For example, at a North American facility that produces heavy oil, when the facility base sediment and water (BS&W) changes, the system automatically adjusts the oil treater unit voltage and frequency relationship to ensure on-spec throughput.

The digital solution also aggregates IIoT sensors to monitor and predict the health of critical valves—enabling the failure prediction and rapid remediation, saving millions in operational downtime and equipment repair.

The second level of service eliminates equipment downtime from your process. This is where we embed data-enriched models of your whole process into a digital avatar to deliver truly dynamic process optimization. Facility models are connected to the production network to provide rigorous fluid modeling from the sandface to the point of sales and proactively manage flow hindrance issues to reduce the cost of production deferment. In one gas processing facility, data-driven models are used to ensure the uptime of acid gas membranes. Specific optimization workflows are implemented to ensure on-spec throughput, adapting operating parameters to the process gas composition and membrane condition.