Methane Lidar Camera

Confidently and unambiguously identify methane leaks.

Locate, visualize, and measure methane emissions, and prioritize remedial actions.

Report accurate methane emissions data continuously

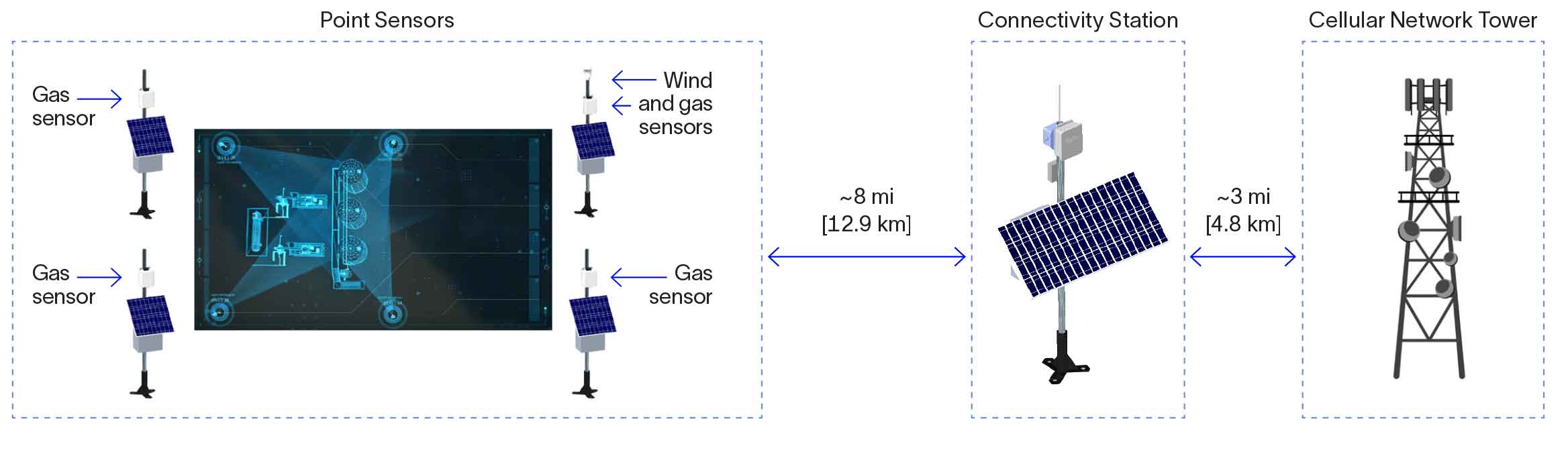

Many oilfield methane emissions come from sources that leak intermittently during normal operations. Continuous monitors can measure these emissions more accurately than is possible with mobile sensors mounted on satellites, airplanes, or drones. The methane point instrument from SLB End-to-end Emissions Solutions is a continuous methane monitoring system that uses IoT-enabled sensors to help you quickly and cost effectively detect, locate, and quantify these emissions. The instrument reports fully interpreted data specifying when the emission occurs, where the source is located, and the emission rate.

Using IoT-enabled sensors placed at the perimeter of the facility, the instrument’s multisensor system detects methane, accurately triangulates the leak location, and quantifies the emission rate. The sensors measure methane concentration with high accuracy under all conditions relevant to the oil field, using an inversion algorithm optimized in one of the world’s largest wind tunnels.

Installation and commissioning typically require less than 8 hours and no onsite ground preparation. Pole installation employs ground anchors and no excavator or concrete is needed, reducing environmental impact. The precommissioned, fit-for-purpose system requires minimal intervention in the field and no intervention once installed, and lack of moving parts minimizes maintenance. Hardware and software precommissioning and optional industrial-grade solar power provide simplicity, ease of maintenance, and cost efficiency at the wellsite. Data are transmitted to the cloud via IoT transmission to provide continuous, secure, real-time data acquisition.

For oil and gas production and processing facilities, onshore; and remote facilities almost anywhere worldwide.

Detects leaks as small as 1 kg/h

Locates the emission source with accuracy of within 19.7 ft [6 m]

Estimates leak rate within a ± factor of two, 68% confidence